Specifications that make a difference. Costs that might surprise you. Choices that can shape a decade of reliability.

You know that feeling when you're facing a decision about equipment worth hundreds of thousands of euros, yet you're still unsure if it's the right choice? Most offers look the same: modern technology, compact housing, easy maintenance. But what about the differences in insulation types, permissible duty cycles, or the total cost of ownership after 15 years of operation?

This guide was created to clear those doubts and give you an edge. We’re not a vendor – we’re a technology partner with years of experience delivering switchgear to industry, renewables, grid operators, and infrastructure construction.

Who is this article for and what will you learn?

If you’re an investor, designer, electrician, technical manager, or responsible for purchasing switchgear, this article will help you:

assess key technical parameters not visible in brochures,

understand the lifecycle of switchgear – from service costs to loss of efficiency,

spot common sales tricks and avoid expensive traps,

compare the most frequently used types: AIS, GIS, and hybrid,

discover the differences in type testing and certifications – things your supplier won’t tell you outright.

At the end of the article, you'll also receive a ready-to-use buying checklist for negotiations with vendors.

Reading time: 4 minutes.

Every second is an investment in the safety and profitability of your infrastructure.

Why investing in wisely selected switchgear matters – the numbers don’t lie

Switchgear is not a “buy and forget” item – it’s the nervous system of your power infrastructure. The right choice at this stage can mean years of smooth operation, and the wrong one? Well, a costly lesson. According to the European Medium Voltage Reliability Survey (2022), as much as 58% of MV infrastructure failures were linked to improperly selected switchgear configurations or components.

What does this mean in practice? The average cost of production downtime in an industrial plant ranges from EUR 15,000 to even EUR 25,000 per day. And that’s not counting reputational damage, contractual penalties, or the stress on your technical team. In other words – saving a few thousand upfront can end with a six-figure invoice by the end of the decade.

Types of switchgear in 2025: AIS, GIS, hybrid – what has changed in recent years?

The world of switchgear isn’t standing still – on the contrary, the last few years have brought a real revolution in design, materials, and investor expectations. AIS (Air Insulated Switchgear) is the classic – easy to service, spacious, but requiring large volumes. GIS (Gas Insulated Switchgear) is the opposite – compact, sealed, precise. And hybrids? A clever mix of both worlds.

Data from the European market shows that between 2018 and 2023, the price gap between GIS and AIS decreased by around 18%, and hybrid solutions (often with partial gas or vacuum insulation) have started gaining significant traction in industrial and urban applications. There’s also the spatial aspect – reducing the footprint by just 1 m² today can save up to EUR 500–600 in construction and ventilation costs. The choice of type is no longer just about price, but about the overall strategy of the investment.

Indoor medium voltage switchgear with control panels and air insulation, Photo Credit: Muhammed Shazin/unsplash

5 key technical parameters every investor should know

Don’t be fooled by glossy folder renders. If you’re unfamiliar with these five parameters, you risk choosing equipment that doesn’t match real-world requirements:

Rated current (In) – determines the maximum safe load. Too low? Expect overheating and shortened service life.

Short-circuit current (Isc) – ensures resilience in critical situations. There’s no room for compromise here.

Insulation level (kV) – affects safety during atmospheric or grid-related overvoltages.

Number of switching cycles – because no one wants to replace a device after just 3 years simply because it exceeded its operational limit.

Protection and communication systems – in an era of automation, a switchgear without a communication interface is like a car without a steering wheel.

Without this data, choosing switchgear is like guessing the calories in a cake without a label – it might work out, but it could just as easily lead to serious indigestion.

Switchgear lifecycle costs: the purchase is just the beginning

You’ll see the supplier’s price once. But operational costs? They’ll appear every year — in service invoices and modernization quotes. That’s where the real story begins.

A well-selected switchgear can have a 30–40% lower Life Cycle Cost (LCC) compared to “bargain” models. A real market example: a device priced at €60,000, poorly adapted to environmental conditions, generated €90,000 in operating costs over 10 years — mainly due to frequent maintenance, component replacements, and unplanned downtime.

Meanwhile, a model that was 15% more expensive, but better tailored, cost just €27,000 to operate in the same timeframe. The difference? The price of a decent electric SUV.

Hidden traps in offers – how to spot them and protect your budget

In the world of technical offers, not everything that shines is a solid choice. Sometimes a tempting price hides an omitted parameter, a simplified test or… serious risks down the road. That’s why it pays to stay vigilant — not out of distrust, but out of care for safety and long-term ROI.

Here are a few things to look out for:

Underrated Internal Arc Classification (IAC)

It sounds technical, but it means that in case of a fault, the internal pressure might not be safely discharged — posing a real threat to both personnel and infrastructure.

Lack of type testing (type-tested switchgear)

If the switchgear hasn’t been fully tested as a system, you can’t be sure how it will behave in real-world conditions. It’s like testing seat belts separately from the car.

Unclear service conditions

Some offers include perks like a “free first inspection”. But what if the technician is only available from a foreign HQ, and the response time exceeds 5 days? That’s not support — that’s a lottery.

Shortened warranty on critical components

Always check what exactly is covered. Five years for the enclosure but only twelve months for the circuit breaker? That’s like getting a longer warranty for your wardrobe door than for the lock itself.

Don’t hesitate to ask questions. It’s not a sign of distrust — it’s a sign of responsibility. After all, you’re the one who bears the consequences of this investment. You deserve to know whether you're buying an armored vehicle built to last — or an aluminum scooter with Wi-Fi and a “premium” sticker..

Certifications, testing and standards compliance: what the nameplate tells you — and what you should ask

The nameplate is a great starting point — it gives you the basics like voltage, current, and applicable standards. But if you're aiming for a complete picture of your switchgear’s safety and quality, it's worth digging deeper.

Ask whether the equipment has passed internal arc tests according to IEC 62271-200, whether the manufacturer shares type test reports, and whether those tests were conducted under conditions that reflect the real operating environment of your installation. These technical nuances make a massive difference — especially in long-term infrastructure projects.

Reliable manufacturers are usually open with documentation: IAC reports (e.g. AFL 20 kA/1s), results of humidity resistance, UV exposure, or corrosion resistance tests. If a supplier responds quickly and thoroughly, it’s a strong sign they know their product inside out — and that you can count on them.

Pro tip: If you don’t get a clear technical answer within 24 hours — maybe wait a bit before signing that order. This is a decision for decades, not months.

Real-world cases: when switchgear selection shaped the future of an investment

Straight from the field (unfortunately):

Case 1: A chemical plant selected AIS switchgear without analyzing ambient humidity. After just 3 years — short circuit, 14-day production halt, total damage: €260,000.

Case 2: An investor installed GIS, but didn’t factor in SF₆ gas recovery after 15 years. End-of-life service cost: €18,000.

Case 3: A city authority opted for a low-cost Chinese product. After 5 years — no spare parts available. Entire installation had to be replaced. Total cost? 138% more than the original investment.

The lesson? Learn from others’ mistakes. And know the people who’ve already been there.

Summary + Checklist

Thank you for taking the time to dive into the topic of switchgear selection. We know this isn’t an easy decision — it takes knowledge, awareness, and a sense of responsibility. But the fact that you're here means you're committed to making smart, informed choices. And that already says a lot.

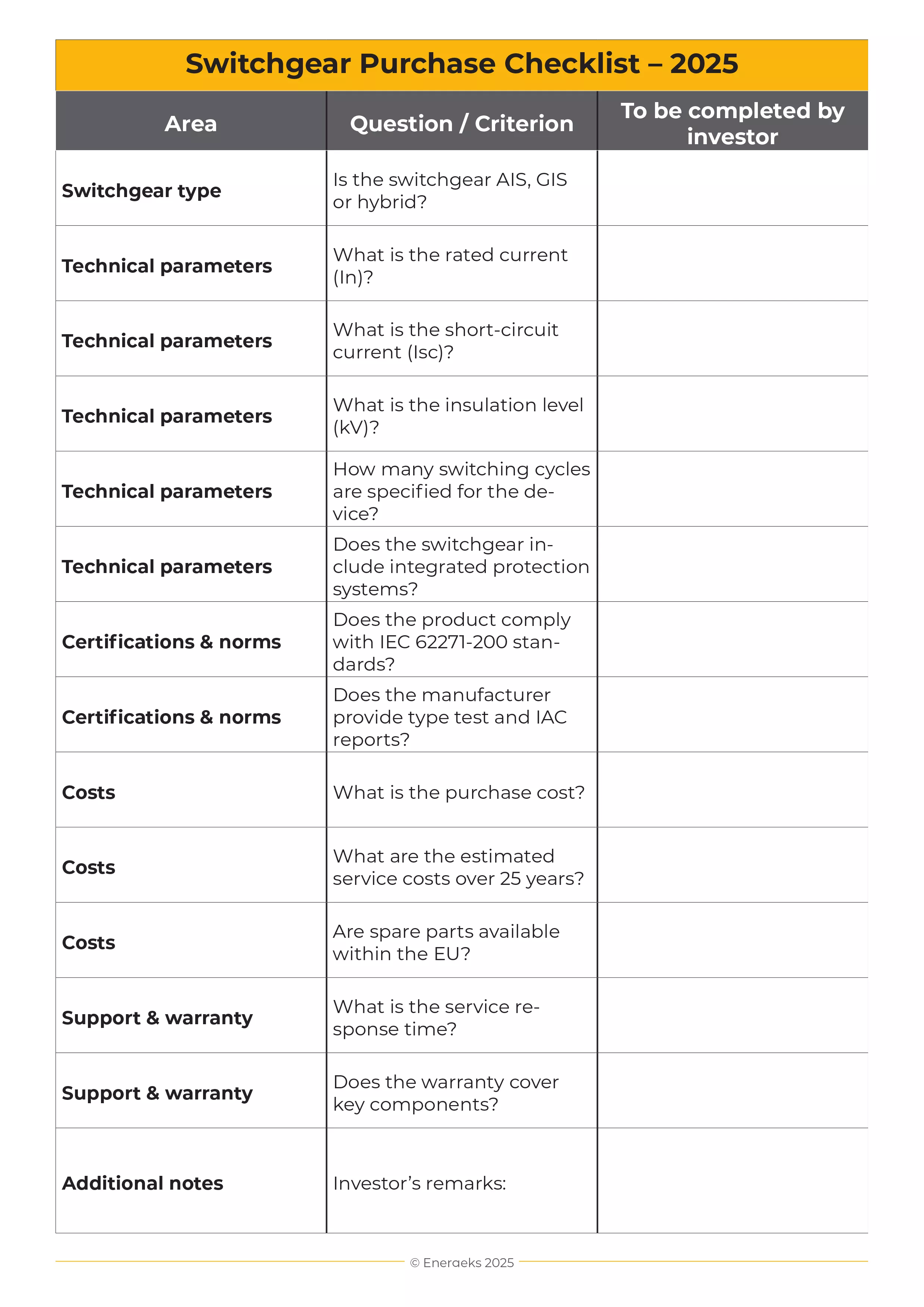

To wrap things up, we’ve prepared a simple, practical checklist you can:

bring with you to supplier meetings,

use while analyzing offers,

treat as a reference point for risk assessment and long-term ROI.

Inside, you’ll find:

questions about standards compliance, testing, and documentation,

fields to fill in the most important technical parameters,

indicators to help evaluate serviceability and life cycle cost.

Switchgear Purchase Checklist, 2025 © Energeks

A switchgear unit is more than just infrastructure — it’s an investment in safety, operational continuity, and long-term peace of mind. If this guide helps you make a decision that pays off in the long run, then we know we’ve done something truly meaningful. Below, you’ll find a preview of the checklist, ready to download or save as an image. Feel free to adapt it to your specific needs.

And if you're looking for ready-made solutions — we’re closer than you think

If, after reading this, you’re ready to take the next step — whether that means finding reliable switchgear or sourcing a transformer that doesn’t have to cross half the globe in a container — you’re in the right place. At Energeks, we believe technology should be available exactly when you need it. That’s why we keep some of our transformer champions in stock, ready to deploy faster than you can say “IEC 62271”. Explore our full transformer portfolio — it’s not just a catalog of promises, but a selection of proven solutions that can power your project today.

Thank you for being here. We’re here to support your technical decisions — wisely, respectfully, and with real-world experience. Join us on LinkedIn and let’s shape the future of power systems together!

Sources:

IEC Standards – Official Site of the International Electrotechnical Commission

Electrical Engineering Portal – Medium Voltage Switchgear Guide

Reviews

No reviews!