At one of the photovoltaic farms an investor asked with a slight smile:

“Why does this transformer say 15.75/0.42 kV when our grid is 15 kV? Is that a design error?”

This question comes up surprisingly often. And while it sounds simple, it goes straight to the heart of what designers and contractors in the medium-voltage world grapple with every day: the transformer voltage ratio.

Because the ratio is not just about “what goes in and what comes out.”

It is a mathematical promise that voltage and current will behave exactly as required by the grid, the inverter, and the Distribution System Operator.

In this article, we will explain what a transformer voltage ratio is, where common ratios come from, how to interpret them, and what they really mean for the efficiency and safety of your installation.

You will also learn why those “odd numbers” on the transformer nameplate are sometimes exactly what saves your investment from overvoltage issues and grid non-compliance.

Estimated reading time: approx. 8 minutes.

What is a transformer voltage ratio and how does it work in a real grid?

The voltage ratio of a transformer is one of those terms that sounds harmless—almost like the proportion of ingredients in a pancake recipe. And yet, in practice, it is a key parameter that determines whether the transformer will function properly or simply become an expensive piece of decoration in the substation.

By definition: what exactly is it?

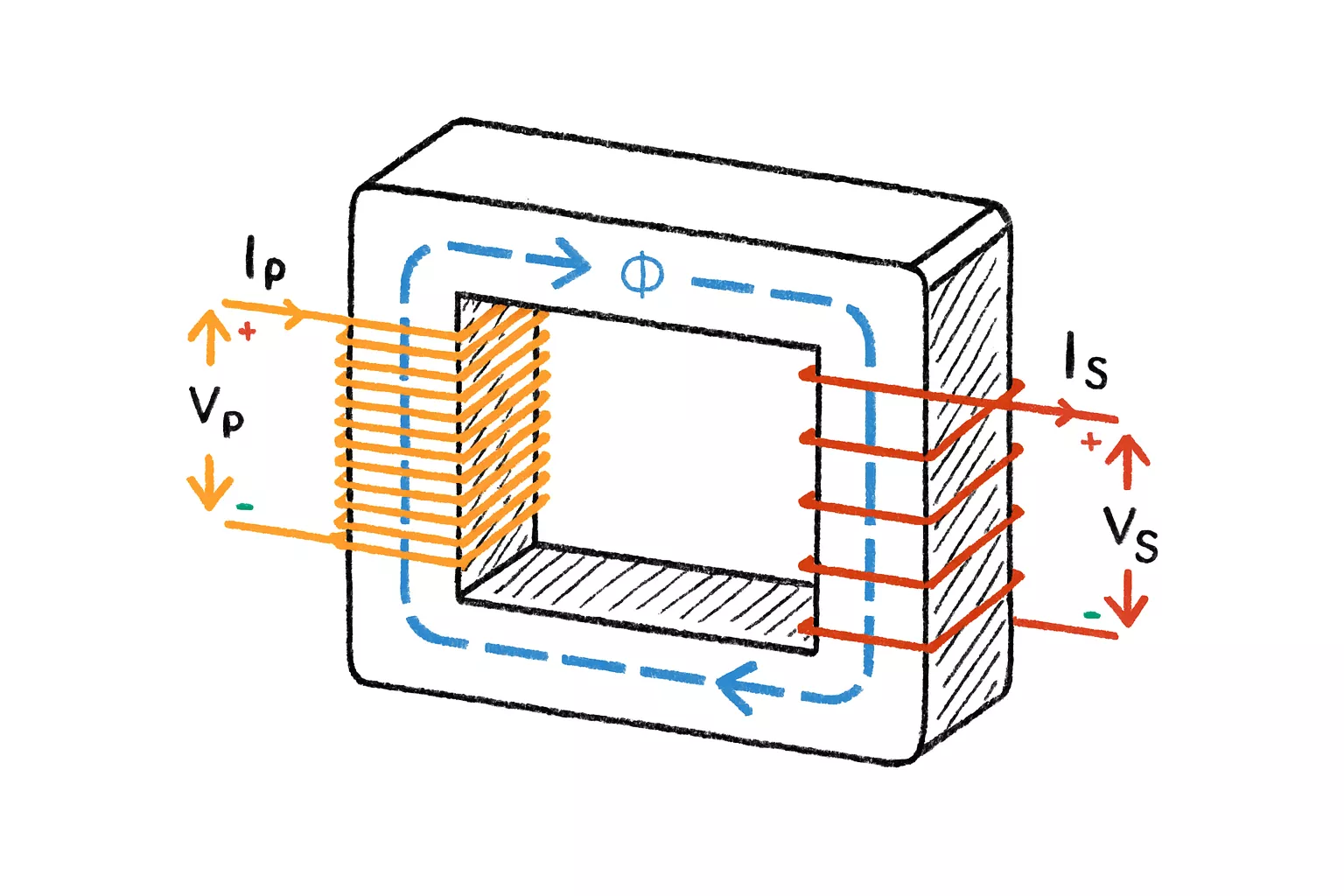

The transformer voltage ratio defines the relationship between the voltage on the primary (input) side and the voltage on the secondary (output) side.

If we have a voltage ratio of 15,000 V / 400 V, it means the transformer steps the voltage down from 15 kV to a safe level of 400 V—suitable for end-use devices such as inverters, servers, machines, pumps, or even a humble electric kettle in a production hall.

According to the law of conservation of power (neglecting losses), the transformer must "balance" voltage and current. If voltage goes down, current goes up—and vice versa.

How does it work in a real grid—not just in the textbooks?

In theory, it’s simple: the grid supplies 15 kV, the transformer steps it down to 0.4 kV, and that’s it. But in reality, things look a bit different. The grid doesn’t hold the voltage steady.

On a hot day, with a million air conditioners running, voltage drops. At night, when barely anything is drawing power, voltage rises. Add solar panels pushing excess energy back into the grid on sunny days, and… you get a rollercoaster.

This is why transformer designers have to account for these fluctuations.

A 15/0.4 kV ratio might work in theory—but what if the grid voltage rises to 15.4 kV? On the low-voltage side, that becomes 411 V instead of 400 V—and that could exceed the tolerance of the inverters.

This is where the magic of engineering comes in: tap changers.

The transformer is equipped with the ability to adjust its voltage ratio by ±2×2.5%—meaning it can raise or lower the input voltage without physically changing the windings.

It works like a thermostat: the transformer adapts to real operating conditions.

A good voltage ratio is one that:

fits the actual voltage at the point of connection (not just on paper),

provides the proper voltage for inverters and loads,

includes a margin for regulation,

allows appropriate selection of protection and switching devices without oversizing.

And that is exactly why transformer nameplates often show values like 15.75/0.42 kV instead of the “neat” 15/0.4 kV.

Because the world isn’t uniform, and the transformer needs to understand that.

Where do typical voltage ratios come from — a story of compromise, grid maps, and engineering flexibility

Imagine an electrical map of Europe, but not with mountains and rivers, but with voltage levels:

10 kV, 15 kV, 20 kV, 30 kV, 13.2 kV…

Each country has built its own system, its own habits, and its own standards—often due to historical, technological, and logistical reasons.

On this map, the transformer is like a multilingual translator who must speak the dialect of a given country, not just in words (voltage), but in tone (current, regulation, tolerances).

Typical voltage ratios—such as 10 kV / 0.69 kV, 15.75 kV / 0.42 kV, 20 kV / 0.4 kV are the result of three forces that every transformer manufacturer must balance:

Local medium voltage (MV) grid levels.

In Poland, the most common voltages are 15 kV and 20 kV.

In Germany, you will find 10 kV, 15 kV, and 30 kV.

In Spain, 13.2 kV and 21 kV are often used.

The transformer must “fit into” this local grid reality, which is why part of the voltage ratio comes directly from the region’s MV level.Output voltage—what the equipment needs.

These are typically around 0.4 kV, 0.42 kV, or 0.69 kV—depending on the installation design, device requirements, and local low-voltage standards.

The output voltage must match what PV inverters or energy storage systems need to operate efficiently.Voltage buffer, tap changer range, and network tolerances.

The grid rarely delivers exactly 15,000 V—it’s often 15,200 V, 15,400 V, or even 14,900 V.

The transformer must include a margin for tap changer adjustments (± a few percent).

That’s why you’ll often see numbers like 15.75 kV—slightly above nominal—to allow room for adjustment without losing synchronization with the inverter.

Those fractions (like 0.75 kV) are not a mistakes, they are a result of engineering precision.

Examples of typical voltage ratios and when to use them

In the world of medium-voltage transformers, there are certain classics—ratios that show up on construction sites as reliably as coffee at 6 a.m. in a design office. Each one has its own logic and technical rationale, shaped by decades of practice, grid conditions, and real-world experience.

Let’s break them down—not just by the numbers, but by their personalities.

The first evergreen: 10 kV / 0.69 kV

This one is a favorite in environments where high power meets smart electronics—think large-scale energy storage systems or EV charging stations.

Why? Because many industrial inverters operate at a nominal voltage of 690 V AC, which aligns perfectly with this ratio.

What makes this setup so effective is its low voltage ratio, which keeps secondary current at manageable levels without overloading the windings. Less stress on copper means better performance and a longer lifespan.

In simple terms: if your project includes power electronics with big appetites, this ratio offers pure stability on a silver platter.

The engineers’ favorite: 15.75 kV / 0.42 kV

Call this one the sweet spot for solar farms in Poland and Germany.

It’s a smart compromise between:

MV grids typically running at 15 kV, and

inverters working best around 400–420 V.

The extra 0.75 kV on the primary side gives headroom for voltage regulation, especially when tap changers come into play. This makes it easier to hit that Goldilocks zone on the LV side—not too high, not too low, just right.

It’s like finding perfect tire pressure for your electric car: quiet, efficient, and ready for any terrain.

This ratio is often chosen when engineers need grid synchronisation and inverter compatibility without the drama of last-minute design changes.

The all-time classic: 20 kV / 0.4 kV

This duo has been powering European infrastructure for decades.

You’ll find it across public distribution systems, municipal buildings, industrial parks—anywhere where compatibility, reliability, and simplicity are king.

It’s a straightforward setup:

20 kV primary, straight into the grid, and 0.4 kV secondary, ready for standard low-voltage panels.

There’s nothing fancy about it—but that’s exactly the point. It’s the transformer equivalent of a solid handshake: dependable, familiar, and trusted by generations of engineers.

Each of these voltage ratios is like a language dialect—speaking the same physics, just with a different accent.

One speaks fluent inverter.

Another chats easily with distribution grids.

The third bridges both worlds with confident ease.

And that’s why the world of transformers is never boring. Behind those neat numbers on the rating plate lies a dance of engineering pragmatism, grid diplomacy, and yes—just a touch of poetry.

How transformer voltage ratio works – in a nutshell

Put simply, a transformer’s voltage ratio defines the relationship between the primary (input) voltage and the secondary (output) voltage.

If a transformer is rated at 15,000 V / 400 V, it means that for every 15,000 volts on the medium-voltage side, there will be 400 volts available on the low-voltage side.

From a user’s perspective, this means the transformer:

steps down the voltage from the MV grid to a safe level for downstream equipment, and

increases the current on the LV side inversely proportional to the voltage ratio.

In other words:

The higher the voltage ratio, the higher the current on the low-voltage side—and vice versa.

This is why we calculate transformer power using the formula:

S = U₁ × I₁ = U₂ × I₂

Where:

S – apparent power (in kVA)

U – voltage (in V)

I – current (in A)

Let’s look at a real-world example:

A transformer rated at 1000 kVA, with a 15/0.4 kV voltage ratio:

Primary current (MV side):

I₁ = S / (√3 × U₁) ≈ 1000 / (1.732 × 15,000) ≈ 38.5 ASecondary current (LV side):

I₂ = S / (√3 × U₂) ≈ 1000 / (1.732 × 400) ≈ 1443 A

As you can see, the same transformer delivers dramatically different currents depending on the voltage.

That’s why selecting a voltage ratio without understanding the load characteristics, protection devices, and grid conditions is a fast track to problems—like tripping breakers, overheated windings, or inverter synchronization failures.

In transformer design, math is not optional—it’s your first line of defense.Phase configurations and their impact on voltage ratio

Sometimes, the winding connection scheme (such as Y-Δ, Δ-Y, Δ-Δ, Y-Y, etc.) affects the effective voltage ratio in a way that differs slightly from the nominal nameplate values.

For example, in Dyn11 configurations (a star-delta transformer with a 30° phase shift), the actual voltage ratio may require correction compared to what’s printed on the rating plate—especially when you're considering line-to-line versus phase voltages.

And if the configuration includes a neutral point (like Dyn11 with "n"), things get even more interesting. The presence of the neutral introduces new considerations for grounding, fault behavior, and voltage balancing. It’s one of those "small details" that turns out to be not so small when your system doesn't behave as expected.

Taps and voltage regulation

Most modern transformers offer tap changers on the primary winding, typically allowing ±2 × 2.5% adjustment range. This enables tuning of the input voltage to match real-world conditions.

So, when you see a transformer rated at 15.75 kV, don’t assume that’s a rigid number. It’s actually the center point of an adjustable range, giving engineers room to fine-tune voltage levels to ensure compatibility with both the grid and downstream inverters.

Think of it like a tone control knob on an amplifier—just enough to correct the pitch without needing to redesign the whole orchestra.

Losses, efficiency and standards

Every transformer design aims to minimize losses—both no-load (core) and load (copper) losses.

European regulations like Ecodesign 548/2014 require new transformers within specified power ranges to meet strict efficiency standards (e.g. Energy Efficiency Level 2 – EEF2).

And here's where the voltage ratio plays a surprisingly indirect role:

A poorly chosen ratio can lead to higher conductor losses,

reduced efficiency in voltage regulation,

and increased heat generation within the windings.

It’s a domino effect. One decimal point off in your voltage ratio, and suddenly your whole installation is dealing with hotter cables, louder hum, and unhappy electronics.

Bottom line?

The voltage ratio is more than a number on a plate—it’s a fine-tuned parameter that balances thermal performance, energy costs, and compliance with regulations.

Why voltage ratio is key to synchronizing with the DSO grid

Distribution System Operators (DSOs) have very precise requirements when it comes to nominal voltage levels at connection points. That’s why a transformer’s voltage ratio must reflect the actual voltage present in the local grid, which often isn’t exactly 15,000 V but rather values like 15,750 V or 15,400 V.

This is crucial to ensure:

Stable operation of PV inverters, which require a supply voltage strictly within the 400–420 V AC range,

Maintaining medium voltage (MV) levels within the ±5% tolerance,

Compliance with standard PN-EN 50160 on voltage quality parameters.

This is precisely why designers often select a 15.75/0.42 kV voltage ratio. It offers enough headroom for safe tap changer regulation (±2 × 2.5%), without risking loss of synchronization or breaching inverter specifications.

Differences between grids in Poland, Germany and Spain

Europe is a mosaic of medium voltage levels.

In Poland and the Czech Republic, the most common voltages are 15 kV and 20 kV.

In Germany, you often find 10 kV, 15 kV, and 30 kV networks.

In Spain, the typical values are 13.2 kV, 15 kV, and 21 kV.

As a result, a substation designer must not only know the nominal parameters of the grid, but also understand the “philosophy” and legacy of local distribution system operators.

For example:

In Germany, there are still 10/0.4 kV networks in operation, where transformers with a 10.5/0.4 kV ratio are commonly used. This allows for proper tap regulation and coordination with old and new infrastructure.

In Spain, 21/0.42 kV transformers are often used because the nominal voltage of 21 kV stems from historical 3×12 kV networks that were later modernized to a 21 kV standard. It’s a legacy system with modern adaptation.

In Poland, the 15/0.4 kV ratio remains the standard in most cases. However, for industrial energy storage systems and high-power inverters, the 20/0.69 kV configuration is gaining popularity due to improved current distribution and lower cable losses.

These variations help explain why the same transformer might be labeled differently depending on the country of delivery.od kraju dostawy.

We design our units in standard voltage ratios like 10/0.4 kV, 15.75/0.42 kV, and 20/0.69 kV, with voltage regulation options of ±3×2.5% or ±2×2.5%, to meet the technical requirements of DSOs in Poland, Germany, and Spain.

Ask us about a configuration tailored to your project.

Once upon a time: the voltage ratio that saved the project

During the commissioning of a PV farm in Lower Silesia (Poland), the team discovered that the actual voltage at the point of connection was 15.6 kV, not the expected 15 kV.

If the transformer had a 15/0.4 kV ratio, the low-voltage side would have supplied 416–418 V to the inverters – exceeding their acceptable input range.

As a result, the system would have shut down every time the grid slightly boosted the voltage.

The use of a transformer with a 15.75/0.42 kV voltage ratio completely solved the issue. That seemingly small 0.75 kV margin on the MV winding turned out to be critical for stable operation and DSO compliance.

For the investor, this made the difference between a running PV farm and one that was non-operational.

Voltage ratio and protection equipment selection

The voltage ratio also determines the rated currents, which affects the selection of cables, current transformers (CTs), circuit breakers, and protection relays.

In real-world practice, an incorrect voltage ratio assumption can flip the entire logic of the project:

Too small a ratio = too high current on the LV side = cable overheating, higher I²R losses, and accelerated aging of insulation.

Too large a ratio = too low LV voltage = inverter undervoltage errors, disconnections, or decreased energy yield.

That’s why standards such as PN-EN 60076-1 and EN 50588-1 recommend that designers always consider the actual voltage at the point of connection, including ±5% tolerance, and the load characteristics (resistive, inductive, capacitive).

In PV and EV systems, an additional factor comes into play: dynamic voltage ratio performance. This refers to the transformer’s ability to compensate for fast changes in voltage, caused by inverter activity or rapid load variations from DC chargers.

It is no longer just about steady-state values – modern transformers must adapt to dynamic grid behavior in real time.

How to select a transformer voltage ratio – a practical example

Let’s assume you are designing a 2 MW substation for a PV farm connected to a 15 kV network, using inverters operating at 420 V AC.

You are choosing between two transformer voltage ratios: 15/0.4 kV or 15.75/0.42 kV.

For an apparent power of 2000 kVA:

15/0.4 kV configuration:

I₁ = S / (√3 × 15 000) = 77 A

I₂ = S / (√3 × 400) = 2887 A

15.75/0.42 kV configuration:

I₁ = S / (√3 × 15 750) = 73 A

I₂ = S / (√3 × 420) = 2747 A

The differences may seem small, but in practice they result in lower LV current, reduced power losses, and lower operating temperatures for the windings.

Over time, this translates into improved system performance and extended equipment lifespan.

Smart and adaptive transformers

A transformer is no longer a passive component in the power network – it has become an active player in maintaining system balance.

Integrated voltage regulators continuously analyze real-time values on both MV and LV sides and adjust the voltage ratio within a ±5% range.

This allows the substation to maintain optimal output voltage, even when loads fluctuate due to inverter operation or DC charging cycles.

This functionality is crucial in next-generation projects, where energy flows both to and from the grid.

In PV farms, battery storage systems, or e-mobility hubs, where the direction of power flow shifts constantly, a transformer with an adaptive voltage ratio becomes the system’s stabilizing core.

Moreover, an increasing number of distribution system operators (DSOs) across Europe are incorporating such features into their grid connection requirements.

It makes perfect sense. As networks become more distributed and less predictable, they require equipment that can think and react.

From an investor’s standpoint, this is not just about performance – it is about pure economics:

Lower energy losses

Reduced O&M costs

Longer inverter lifespan

No need for manual corrections – the substation begins to learn its own load profile.

In a world heading toward smart grids, the voltage ratio becomes a strategic parameter, not just an electrical one.

It defines your system’s energy efficiency, grid compliance, and resilience.

You could say that the transformer of the future is made not only of steel and copper, but also of logic and algorithms.

The future

Just a decade ago, voltage ratios were considered set in stone.

Once selected, a transformer would operate for 30 years unchanged, regardless of network variations or load shifts.

Today, that is no longer the case.

Modern designs – such as Energeks MarkoEco2 – offer automatic voltage regulation based on real-time load conditions.

This means the voltage ratio is no longer fixed – it can adapt within a ±5% range, keeping the LV side voltage stable even when the MV grid fluctuates.

Such solutions are now often required by DSOs in large-scale PV plants, energy storage systems, and EV charging stations.

As a result, the voltage ratio is evolving from an electrical specification into a strategic asset for ensuring system efficiency and long-term reliability.

If you are planning to invest in a transformer that understands the new logic of the grid, take a look at our offer:

→ Medium voltage transformers – full Energeks portfolio

You are also welcome to join our Energeks LinkedIn community, where we share knowledge, real-world experiences, and insights into the future of energy – always with gratitude for every partnership.

Because while technology builds the hardware, it is people and relationships that create a system that truly works.

Źródła:

European Commission – Regulation (EU) 2019/1783 supplementing Regulation (EU) 548/2014: Ecodesign requirements for power transformers

Forbot: Transformator – budowa, zasada działania i zastosowanie

Reviews

No reviews!