Every transformer is an engineering masterpiece, and its efficiency and durability largely depend on the proper design of its windings. These components are responsible for energy transfer, as well as the electrical and mechanical stability of the device, acting as the backbone of the entire structure. Dive into the fascinating world of transformer windings and discover how their precise construction impacts the reliability of power networks. Reading time: 1.5 minutes.

Foundations of Winding Design

Transformer windings must meet a range of requirements to satisfy both technical and economic demands:

Cost Efficiency:

The choice of materials, such as copper or aluminum, depends on their market prices and the potential for production cost optimization.Thermal Resistance:

Exceeding permissible temperatures significantly shortens the device's lifespan, much like overloading a car engine.Mechanical Stability:

Windings must withstand the forces generated during short circuits, which can reach destructive levels.Electrical Strength:

High voltages and surges demand precise selection of insulation and proper winding arrangement.

Often, these requirements are contradictory – higher current density reduces the amount of copper used but increases energy losses. It’s an engineering art of compromise, akin to balancing on a tightrope between efficiency and durability.

Materials: Copper or Aluminum?

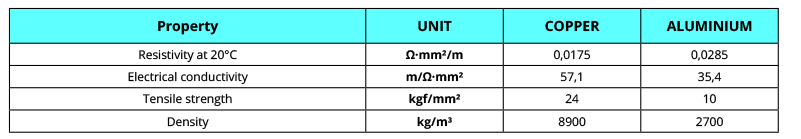

The primary materials used in windings are copper and aluminum, each with unique properties:

Tab 1.

Copper, like an Olympic sprinter, offers excellent conductivity and mechanical strength. Aluminum, being lighter and cheaper, requires larger cross-sections to match the performance of copper.

When to Choose Copper and When Aluminum?

Copper:

Preferred in high-power transformers where efficiency and mechanical stability are crucial, such as in transmission or industrial energy systems.Aluminum:

Suitable for devices where cost and weight reduction are essential, such as distribution transformers or mobile applications.

Thanks to the variety of available materials, a transformer can be precisely tailored to the technical and economic requirements of a given project.

Winding Geometry: The Art of Precision

The design of transformer windings can be compared to bridge architecture – every element must fit perfectly to ensure stability and durability. Precise winding arrangements provide not only electrical reliability but also optimal cooling conditions and minimized energy losses.

Concentric Windings

Concentric windings are widely used in core-type transformers. They feature a configuration where high-voltage (HV) and low-voltage (LV) windings form coaxial rings.

This arrangement offers several benefits:

Cooling:

The spaces between windings enable effective circulation of transformer oil, which efficiently dissipates heat.Insulation:

This configuration makes it easier to provide the required level of electrical insulation, especially at high voltages, which is critical for safety and reliability.

Concentric winding arrangements are mainly used in high-power transformers where mechanical stability and uniform magnetic field distribution are priorities.

Examples of Concentric Winding Applications:

High-Voltage Transmission Transformers:

In transmission networks of 220 kV and above, concentric windings are used in high-power transformers (e.g., 400 MVA), where mechanical stability and uniform cooling are crucial. These transformers are typically employed in major substations transmitting energy over long distances.Industrial Transformers for Foundries and Mines:

Concentric windings are highly effective in transformers handling high current values (e.g., in aluminum smelters or copper mines), where heavy loads occur. Efficient oil cooling allows operation in demanding environmental conditions.Hydropower Plant Transformers:

Hydropower plants often use transformers with a capacity of 100 MVA or more, where concentric windings provide high reliability. These devices must handle load fluctuations and ensure efficient heat exchange in remote installations far from maintenance services.Railway Electrification Transformers:

The high demands for continuous operation and mechanical resistance in transformers used for railway power systems (e.g., 25 kV AC) highlight the effective use of concentric windings. They help minimize the risk of failure under continuous load.Offshore Transformers:

Concentric windings are used in transformers on drilling platforms and offshore wind farms. They offer resistance to harsh environmental conditions, and their construction allows for effective cooling in limited spaces.Data Center Transformers:

In large data centers, where transformers operate at full capacity 24/7, concentric windings help maintain voltage stability, minimize losses, and ensure efficient heat dissipation.

Sandwich Windings

Sandwich windings dominate in shell-type transformers. Their characteristic feature is the alternating arrangement of HV and LV winding sections, which effectively reduces leakage reactance.

Operating Temperature Range

Sandwich windings in shell-type transformers must be designed with efficient heat dissipation in mind. Typical operating temperature ranges are:

Insulation operating temperature: 105–180°C (depending on the insulation class, e.g., Class H: up to 180°C).

Transformer oil temperature rise: Typically limited to 50–65°C above ambient temperature.

Effective cooling, facilitated by numerous spaces between winding sections, maintains temperatures within safe limits, extending the transformer’s lifespan.

Leakage Reactance Values

The alternating arrangement of HV and LV winding sections significantly reduces leakage reactance. Typical values are:

Leakage reactance: 3–6% for standard shell-type transformers.

Energy loss reduction: Up to 10–15% compared to other winding types, especially under nominal load.

Low leakage reactance increases transformer efficiency, which is critical for applications requiring high voltage stability.

Cooling Optimization

Numerous gaps between the sections of sandwich windings enable more effective circulation of transformer oil, significantly reducing the risk of overheating. In practice:

Cooling Efficiency:

Sandwich windings can lower operating temperatures by 5–10°C compared to concentric windings.Insulation Degradation Reduction:

Improved cooling significantly extends the lifespan of insulation and the entire device, reducing the risk of failure.

Examples of Applications for Sandwich Windings

Transformers for Steel Mills:

Sandwich windings are preferred in electric arc furnace (EAF) transformers with capacities up to 200 MVA. Low leakage reactance allows for precise control of the metal melting process.Transformers for Power Systems:

In critical substations, such as those supplying hospitals or data centers, the reduced leakage reactance of sandwich windings minimizes energy losses and stabilizes voltage, increasing the reliability of power supply.Traction Transformers:

Sandwich windings are used in shell-type transformers for electric railways. Their efficiency in reducing energy losses and rapid cooling capability ensures reliable operation in highly demanding systems.Industrial Transformers in the Chemical Sector:

In chemical production facilities, where transformers must operate under harsh environmental conditions, sandwich windings provide predictability and stability in managing heavy loads.

Other Types of Windings

Depending on the application and technical requirements, various types of windings are used, each with unique properties:

Cylindrical Windings:

These have a layered construction and are used in medium-voltage transformers, primarily for HV and LV windings in smaller units.Helical Windings:

Ideal for high-power transformers where current is high and the number of turns is small. Special spacers between layers improve cooling efficiency.Crossover Windings:

Mainly used in high-voltage windings of small transformers, where a large number of turns are needed with a small conductor cross-section.Continuous Disc Windings:

These are characterized by a design with discs connected in series or parallel. They are used in both HV and LV windings of large transformers.

Each of these types is designed to address specific engineering challenges, offering unique advantages for transformers of different capacities and purposes. Optimizing winding geometry is therefore key to achieving maximum efficiency, durability, and safety of the device.a.

Current Distribution Optimization

In modern transformers, minimizing energy losses is one of the most critical engineering challenges. Eddy current losses, which occur in conductors under the influence of a varying magnetic field, can significantly reduce the efficiency of the device.

To prevent this, an advanced technique called conductor transposition is employed.

How Does Conductor Transposition Work?

Transposition involves interweaving conductors in such a way that each section occupies different positions relative to the magnetic field of the transformer core. This process can be likened to the meticulous weaving of a tapestry, where every piece is precisely placed to create a harmonious pattern. In technical terms:

Current Balancing:

Conductors are interwoven to eliminate differences in impedance between individual sections.Minimization of Energy Losses:

Reducing the effects of eddy currents leads to less winding heating and improved transformer efficiency.Reliability Improvement:

Uniform current distribution protects conductors from excessive localized loading, thereby increasing the device's lifespan.

Practical Application of Transposition in Windings

Conductor transposition is used in both high- and low-voltage windings. It is particularly crucial in high-power transformers, where intense eddy currents can greatly impact the performance and safety of the device.

The transposition process can be compared to a symphony orchestra, where every instrument – despite its unique tone and sound – must work in perfect harmony to create a unified melody. Similarly, the conductors in a transformer, even when positioned differently relative to the magnetic field, cooperate to ensure uniform current flow. Without this precision, "discords" in the form of energy losses, overheating, and efficiency drops would arise.

Conductor transposition is therefore one of many advanced engineering techniques that optimize transformer performance and set new standards in the energy sector.

Benefits of Conductor Transposition

Uniform Current Distribution:

Transposition eliminates differences in impedance between individual conductor sections, ensuring that current is evenly distributed. This prevents localized overloading, which could lead to insulation degradation and overheating.Energy Loss Reduction:

The process minimizes the effects of eddy currents, which would otherwise cause unnecessary heating of the windings. In practice, this can result in power loss reduction of up to 10–15%.Extended Lifespan:

Even current distribution reduces localized overheating of conductors, increasing the durability of insulation and conductive materials. As a result, the transformer can operate reliably for a longer period.Improved Electrical Stability:

Conductor transposition minimizes magnetic disturbances that could affect neighboring system components, enhancing the overall stability of transformer operation

The Future in Your Hands: The Perfect Transformer by Energeks

A transformer is more than just a device – it is the heart of modern energy infrastructure. We know that only innovative approaches and the highest quality can meet the challenges of the future. That’s why we invest in advanced technologies and materials to make our transformers more efficient, lighter, and more reliable.

Our transformers are designed for long-term, trouble-free operation.

Precise selection and design of windings are the foundation on which we build our devices. This ensures that every unit delivers reliability you can count on, regardless of project scale – from local substations to large industrial installations.

Your needs come first. At Energeks, we believe that reliability is not just about technology but also about building relationships with our clients. We provide comprehensive support at every stage of your order: from technical consulting and design to delivery and service. Our goal is not just to supply devices but to build trust and shared success.

Get in touch with our team of experts. Together, we’ll create a transformer that meets your requirements and rises to the challenges of the future.

Energeks – The Power of Trust and Technology!

Sources:

Reviews

No reviews!