Energy infrastructure security

Accessories and equipment for transformers. What's worth having on hand?

Anyone who has worked with transformers for more than one season knows this scenario.

The documentation checks out, the parameters are calculated, the handover passed without remarks.

The transformer is in place. It's operating. And for a long time, nothing happens.

Then one day, an alarm sounds, there's a smell of heated oil, or irritating vibrations spread through the entire station. That's when the sentence we all know is uttered:

But everything was brand new! 🤬

The problem is that a transformer is never a solitary device.

It's the center of a small ecosystem. Current, heat, vibrations, moisture, dust, mechanical stresses. They all circulate around it daily. Accessories aren't just aesthetic or catalog add-ons.

They are the tools that allow this ecosystem to remain stable.

This article is a map for thinking about which transformer accessories are worth considering from the start, because later they become the answer to questions that arise under stress, often after the fact.

Reading time: ~10 min

Why transformer accessories determine trouble-free operation

A transformer ages slowly and very consistently.

Insulation loses its properties with temperature.

Oil degrades faster if it's not monitored.

Mechanical vibrations, even minor ones, can over years cause more damage than a single overload.

These are processes you can't see at first glance.

That's why experienced operators say plainly: a transformer without monitoring accessories is a device operating in the dark. And working in the dark always ends in reaction instead of prevention.

In the following chapters, we'll go through the most important groups of accessories.

From electrical components, through temperature measurement and monitoring, to mechanics and cooling.

Each one addresses real problems that genuinely occur.

Insulators and connections, or the first line of electrical peace

It always starts with the connection.

And that's not a coincidence or a figure of speech.

All the electrical systems in the world, regardless of voltage and power, boil down to one question:

how to safely and stably transfer energy from one element to another?

Cable, busbar, transformer termination.

It is precisely at this point that two orders, which by nature don't get along, meet.

The electrical order and the mechanical order.

On one hand, we have voltage, electric field, current, temperature.

On the other, mechanical forces, vibrations, thermal expansion, the weight of conductors, and movements resulting from the operation of the entire system.

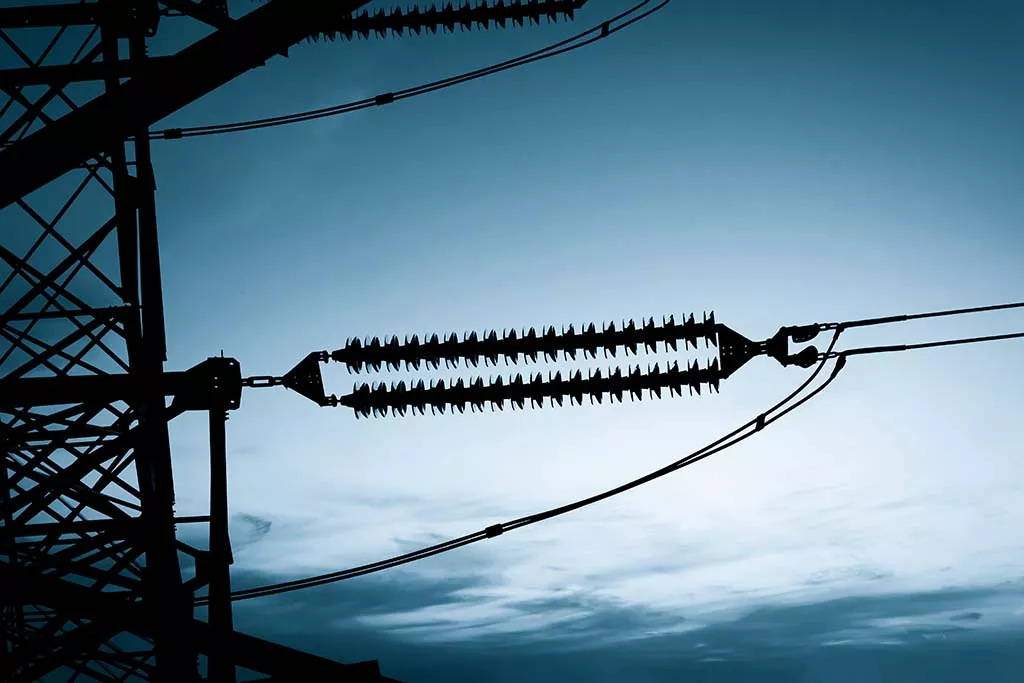

The insulator is the element that must reconcile these worlds.

It must provide electrical insulation while simultaneously transferring mechanical loads.

It must maintain the geometry of the connection while preventing discharges.

It must be invisible in daily operation but absolutely reliable for years.

It is precisely at these connection points where problems most often begin, remaining hidden for a long time.

Local overheating due to insufficient contact pressure.

Surface micro-discharges that don't yet trigger protection but already degrade the insulation.

Slight loosening of connections caused by heating and cooling cycles.

The transformer as a whole may appear healthy, while its weakest points are operating at the edge of tolerance.

In the case of medium-voltage cable terminations, the method of securing the conductor is fundamental. A cable is not a static element. It changes its length with temperature, transmits vibrations, and is sometimes subjected to additional installation stresses. If the connection lacks controlled pressure, contact resistance appears.

And where there is resistance, heat appears.

In practice, the question often arises: what insulator to choose for a medium-voltage cable termination?

In such cases, medium-voltage cable terminal insulators are used, which provide a stable connection and controlled conductor pressure. Their task is not just electrical insulation.

They actively stabilize the connection.

They ensure uniform and repeatable conductor pressure, regardless of whether the installation is operating in winter at low temperatures or in summer under full load.

This solution is particularly important in stations where cables are long, heavy, or routed in a way that generates additional mechanical forces.

A well-chosen insulator with a terminal ensures the connection maintains its parameters not just on the day of handover, but also after 5 or 10 years of operation.

In installations based on busbars, the problem looks somewhat different.

A busbar is rigid, massive, and transmits much greater forces.

There is no room for random tolerances here.

Precision in positioning and resistance to vibrations resulting from high current flow and electrodynamic phenomena are what count.

Insulators with busbar clamps serve as precise support and guide points.

They maintain a constant system geometry, prevent busbars from shifting, and protect connections from loosening. Thanks to them, contact parameters remain stable even during prolonged operation under high load. This is especially important in industrial installations where a transformer doesn't operate occasionally, but daily, often close to its design limits.

Oil-air bushings are a separate category.

They are responsible for one of the most difficult tasks in the entire transformer.

Safely transitioning voltage from the oil-filled interior to the outside, to the air environment. In this single element, different dielectrics, different tempreatures, and different environmental conditions meet.

An oil-air bushing must be sealed, resistant to aging, contamination, and moisture.

Any weakening of its properties can lead to surface discharges, and in extreme cases, to a loss of the transformer's seal. Silicone versions are increasingly chosen today because silicone handles contamination, rain, UV radiation, and variable weather conditions excellently. Even when the insulator's surface isn't perfectly clean, silicone retains its dielectric properties.

This is precisely why silicone oil-air bushings have become the standard in modern transformer stations. Not because they are trendy, but because they better withstand the real world.

And the real world, as we know, is rarely laboratory-clean ;-)

In environments requiring particular mechanical flexibility, EPDM (Elastimold) insulators are also used. EPDM is, in simple terms, a special type of technical rubber, designed to work where ordinary materials would quickly give up. It's not soft rubber like in a tire nor brittle like plastic. It's an elastomer, i.e., an elastic material that, after deformation, returns to its shape and doesn't lose its properties for years.

You could compare it to a very durable seal that doesn't harden in the frost, doesn't crack in the sun, and doesn't crumble over time. EPDM withstands continuous vibrations, temperature changes from frost to high heat, and the effects of moisture and ozone present in the air.

In practice, this means that components made of EPDM don't 'age nervously'.

They don't crack suddenly, don't lose elasticity, and don't require frequent replacement.

Therefore in compact transformer stations and prefabricated solutions, where everything works close together and is subject to constant micro-movements, EPDM performs significantly better than rigid insulating materials.

Tapered bushings, or safe passage through the housing

A tapered bushing is a component rarely talked about until it starts causing problems.

And it is precisely this component that is responsible for one of the most critical points in a transformer:

the passage of voltage through the housing.

Leaks, micro-cracks, improper installation.

Any of these factors can lead to moisture ingress into the insulation and, consequently, to accelerated transformer aging.

That's why tapered transformer bushings are no place for compromises.

A well-chosen bushing ensures electrical stability, oil tightness, and mechanical strength. In practice, its quality directly translates to the lifespan of the entire device.

In many cases, upgrading the bushing solves problems that were previously attributed to the windings or oil.

Oil and winding temperature, or what really ages a transformer

If there is one parameter that most affects a transformer's lifespan, it's temperature.

A transformer doesn't wear out because it's old.

It wears out because it's too hot.

Sometimes just a little too hot, but for long enough.

In the physics of electrical insulation, there is no mercy or romanticism. There is temperature and time. The rest are consequences.

For decades, it has been known that every increase in winding temperature above the design value dramatically accelerates insulation aging. Every 6 to 8 °C above the nominal operating temperature can halve the insulation's lifespan.

This isn't a textbook curiosity; it's hard operational reality.

For a transformer, this means a reduction in life not by a few percent, but by half.

And most interestingly, this process happens quietly. Without sparks, without noise, without an alarm at startup.

The oil in a transformer cannot be treated solely as an insulating medium.

It is primarily a carrier of information about the device's condition. Its temperature speaks volumes about what's happening inside, even when the windings are still invisible and inaccessible. Therefore, measuring the oil temperature is not an add-on or a premium option. It's an absolute minimum if we want to know how the transformer is really performing.

The simplest and still very effective form of control is transformer oil temperature indicators. Mechanical, without electronics, resistant to environmental conditions. Their huge advantage is immediacy.

A single glance is enough to know whether the device is operating within a safe range or is starting to approach limits that are better not exceeded too often.

When the installation becomes more demanding and loads variable, information alone is no longer enough. This is where temperature controllers, such as the CCT 440, working with PT100 sensors, come into play. This is no longer just measurement. This is temperature management.

Automatic cooling activation, alarm signals, the possibility of integration with a superior system. The transformer stops being mute and starts actively communicating its state.

PT100 sensors for transformers have become standard for a reason.

They are stable, precise, and predictable.

They can be used for both oil temperature measurement and direct winding measurement.

It is precisely they that provide the data which allows for a reaction earlier, before elevated temperature turns into a real operational problem.

DGPT2 Monitoring and RIS Systems - or when a transformer starts to speak

A transformer communicates with its surroundings constantly.

It never operates in silence. It is always signaling something.

It changes oil temperature, reacts with increased pressure inside the tank, generates gases resulting from insulation aging or local overloads.

These phenomena occur regardless of whether anyone is observing them.

The problem is that without appropriate sensors, these signals remain unnoticed.

For the transformer, this is its natural language. For a person without monitoring, it's just background noise.

And it is precisely in this space between phenomenon and information where failures occur, later labeled as 'sudden'.

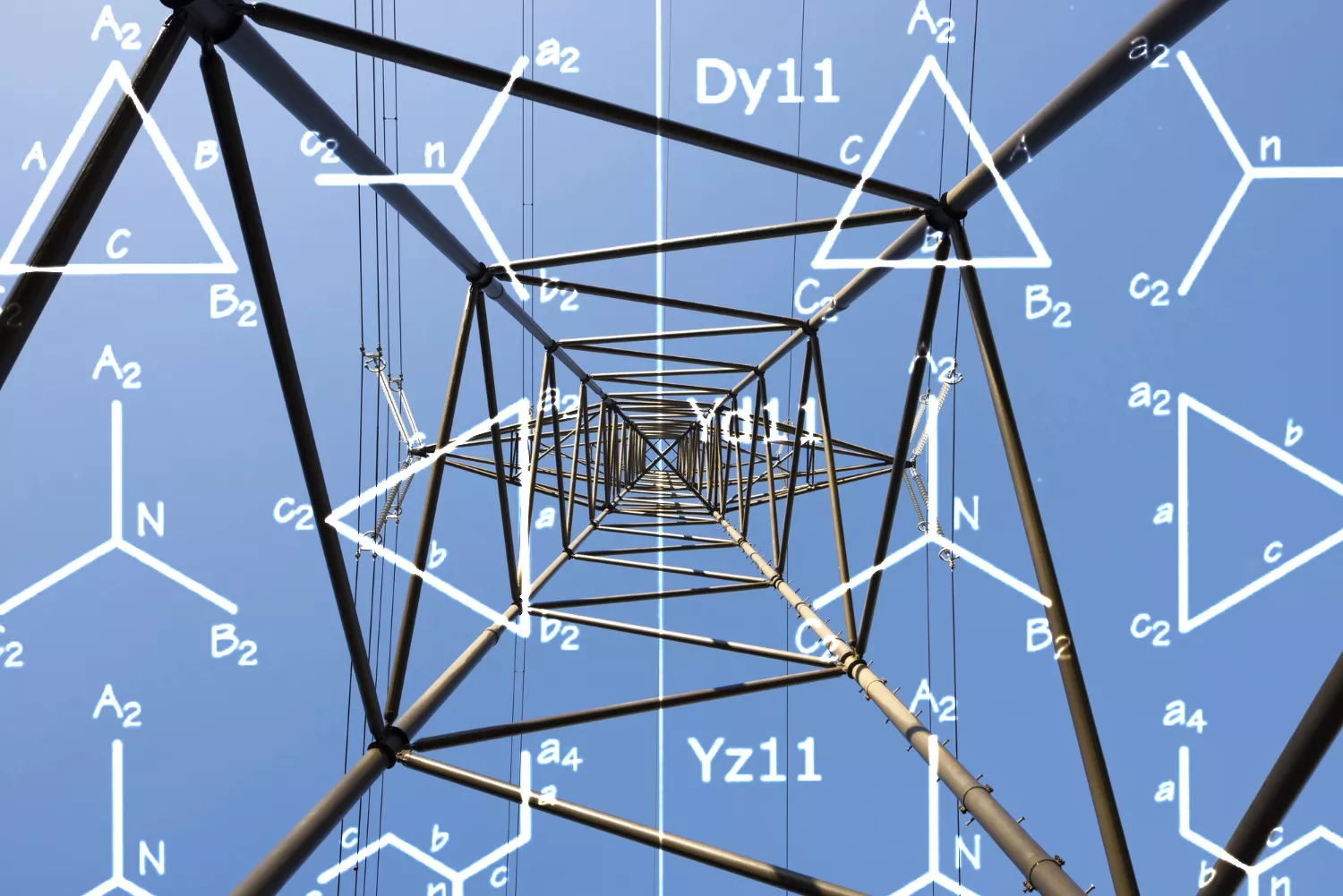

The DGPT2 system is a classic protective and measuring device used in oil-immersed transformers.

It monitors three basic parameters: Gas, Pressure, and Temperature.

The presence of gas signals processes occurring in the oil and insulation.

A rise in pressure informs about dynamic changes inside the tank.

Temperature allows for assessing the transformer's thermal load.

DGPT2 operates locally and provides clear alarm signals or triggers protective actions.

The RIS system, on the other hand, is a strictly monitoring solution focused on observing trends and analyzing the transformer's condition over time.

It collects data, archives it, and enables interpretation without the need to shut down the device.

Thanks to this, an operator can see not only that a parameter was exceeded, but also how it happened. Whether the temperature rose gradually or suddenly. Whether pressure changes are one-off or repetitive.

Not long ago, both DGPT2 and RIS systems were mainly associated with large transmission stations. Today, they are increasingly used in medium-sized industrial installations and renewable energy farms.

The reason is simple and very pragmatic.

Installation downtime costs more than a monitoring system.

Thanks to such solutions, the operator doesn't learn about a problem at the moment of failure or protective device operation.

They learn earlier, when they still have time to make a decision.

They can schedule maintenance, adjust the load, or check cooling conditions.

The transformer ceases to be a black box and starts being a device that speaks before it starts screaming.

Vibrations and mechanics, the signs of a transformer's life

A transformer vibrates.

Always.

Even a brand new one, fresh after handover, that still smells of paint.

This is not a factory defect or a sign of problems.

The magnetic field, electrodynamic forces, and the core's operation cause the device to live by its own, very subtle rhythm. This isn't visible in catalog data, but it's audible and tangible in the real world.

The trouble begins when these natural vibrations don't stay where they should.

Instead of dissipating within the transformer's structure, they travel further.

To the foundation, to the station housing, to building walls, and sometimes even to neighboring equipment. Then a faint humming appears, followed by irritating noise, and after years, minor cracks, loosened bolts, and components that have... simply shifted apart.

Vibration damping pads for transformers are one of those accessories that rarely impress at the project stage but earn huge points during operation.

They act like shock absorbers. They isolate vibrations from the rest of the structure, reduce noise, and ensure the foundation doesn't have to participate in every impulse of the transformer's work.

It's a simple, somewhat underappreciated, and very effective solution.

In many facilities, it's precisely the lack of vibroacoustic separation that turns out, after years, to be the cause of mechanical problems described with one word: wear and tear.

And the truth is often more prosaic. The transformer was simply gently reminding everyone of its existence the whole time, and no one gave it pads so it could do so more quietly.

Ventilation and cooling, or when nameplate power meets summer

Every transformer has its proud rated power listed in the documentation.

The numbers match, the calculations too. The problem is that these values are very often derived under conditions with only moderate connection to reality. A friendly ambient temperature. Proper ventilation. No heatwaves, no dust, no enclosed station standing in full sun.

And then summer comes.

Concrete heats up like a frying pan. The air in the station stands still.

The transformer does exactly what it always does: dissipates heat.

Only suddenly, it doesn't really have anywhere to put it.

And here begins the real verification of nameplate power.

Transformer overheating rarely starts dramatically.

First, there are a few extra degrees on the oil. Then more frequent fan operation, if there are any at all. Sometimes the need arises to limit load during peak hours.

Seemingly nothing serious, but each such episode adds its brick to the accelerated aging of the insulation.

AF fans for transformer cooling are the answer precisely for this moment when theory meets climate. Their task is simple and very specific. To increase heat exchange where natural convection is no longer sufficient.

Without interfering with the transformer's construction, without replacing it, without a revolution in the design.

That's why AF fans are used both in new installations, as a planned element from the start, and in the modernization of existing stations.

They often appear where a transformer is technically sound, but its operating conditions have changed over time. Greater load. A different consumption profile. Higher ambient temperatures than a decade ago.

In practice, it's precisely additional cooling that very often solves a problem that previously seemed serious.

Instead of constantly balancing on the edge of its power rating, the transformer returns to calm operation.

Instead of plans for costly replacement, reasonable support for heat dissipation is enough.

Cooling doesn't magically increase a transformer's power.

It allows it to safely utilize what it already has.

And in operation, that can be the difference between comfort and constantly worrying if it's going to be too hot again today.

Accessories as a system, not an add-on

The biggest mistake in approaching transformer accessories is treating them like a list of options to tick off at the end of a project. One here, another there, just to have them.

Meanwhile, in real operation, they don't work separately.

They cooperate. They form a system of safety, control, and daily operational comfort.

Insulators ensure energy has a stable path.

Bushings guard the boundary between the interior and the external world.

Sensors and monitoring provide information before a problem appears.

Vibration pads and fans take care of mechanics and temperature, things that work continuously, even when no one is looking.

Each of these elements addresses a very specific situation that, in practice, happens more often than we'd like.

A transformer equipped with such accessories isn't more complicated.

It's simply more resilient to reality. To summer, to variable loads, to vibrations, to time. And time, as we know, is the most demanding test for any installation.

If you've made it to this point, it means you think about transformers not as catalog objects, but as systems that need to work for years.

At Energeks, we believe in a partnership approach. We don't look at a transformer as a single device taken out of context, but as an element of a larger system that must operate stably for years. That's why, when designing and selecting transformers, we always consider the operating conditions, future load, and the realities of operation.

If you want to see which transformers and system solutions best fit your installation, we invite you to explore the Energeks offer.

And if you'd like to stay longer, exchange knowledge, and see what the world of transformers really looks like behind the scenes, join us on LinkedIn.

This blog is an invitation to systems thinking. And to further conversations.

Sources:

IEC 60076-1: Power Transformers - General Standard via studylib.net

Winter rarely arrives with a bang.

It more often creeps in quietly.

First, a few chilly mornings.

Then dampness that doesn't disappear even at noon.

And finally, small, easy-to-ignore signals. The transformer is operating. Parameters are still within spec. Nothing is whining. Nothing is sparking. And that's precisely when the problem begins.

Water vapor condensation inside a transformer tank doesn't produce spectacular symptoms.

It doesn't shut down the grid in one day. It doesn't send an SMS alarm. It works like a slow corrosion of trust. Accumulating on the tank walls, in the paper insulation, and in the oil, it systematically reduces the electrical withstand strength of the system.

This is a topic that returns every winter. And almost always when it's already too late.

For years, we have worked with medium-voltage transformers in real operating conditions.

We have seen transformers that were correctly sized electrically, met EcoDesign Tier 2 requirements, had complete documentation, and new oil.

And yet, after two or three winter seasons, they started causing problems.

The common denominator was very often moisture.

Water vapor condensation is not a manufacturing defect. It's a physical phenomenon.

This text is for everyone who wants to understand what really happens inside a transformer tank in winter and how to prevent it before the quiet killer starts counting the losses.

After reading, you will know where the water in a transformer comes from, why the problem intensifies in winter, what the real consequences are for the insulation, and how to mitigate the risk through both design and operation.

Reading time: 12 minutes

Where does water vapor in a transformer tank come from

Air always contains water.

Even when it seems dry.

Relative humidity is not an abstract parameter from a weather forecast. It is the actual amount of water vapor that can condense when the temperature drops.

A transformer tank is a closed space, but it is rarely perfectly sealed in the physical sense. Even hermetic constructions have micro-phenomena of diffusion.

Add to this moments of opening, transportation, installation, oil filling, and maintenance work.

If air with a specific humidity enters the tank interior, and then the temperature of the tank walls drops, water vapor begins to condense.

The dew point is often reached faster than we expect.

In winter, this mechanism works mercilessly.

During the day, the transformer operates, the oil heats up, and the air inside increases its capacity to carry moisture.

At night, everything cools down.

The water vapor seeks the coldest surface.

Most often, these are the upper parts of the tank and structural components

Why winter acts as a catalyst for the problem

Winter is a season of large temperature amplitudes. A difference of several dozen degrees between day and night is not unusual. For a transformer, this means the cyclic breathing of the oil and air volume.

The key concept here is the dew point. This is the temperature at which air with a given relative humidity can no longer keep water vapor in a gaseous state.

For example, air with a relative humidity of 60% at a temperature of 20°C reaches its dew point at around 12 degrees.

This means that any surface colder than this threshold becomes a site for condensation.

The walls of a transformer tank in winter very often have a temperature significantly lower than the air inside. Especially the upper parts of the tank, the covers, and structural components protruding above the oil level. That is where water vapor condenses first.

In breathing transformers, every cooling cycle means drawing in air from the outside. If the air dryer is worn out, incorrectly sized, or simply forgotten, moisture enters the interior. At temperatures near zero, the air's capacity to store water vapor drops sharply, so condensation occurs almost immediately.

In hermetically sealed transformers, the phenomenon is subtler but still exists. Oil changes volume with temperature.

With a temperature drop of 20°C, the oil volume can decrease by about 1%.

In a tank with a capacity of several thousand liters, this means real changes in pressure and the performance of seals.

Moisture doesn't enter through the door, but it enters through the window of physics. The diffusion of water vapor through sealing materials is slow but non-zero. Winter gives it time and favorable conditions.

Additionally, in winter, the transformer often operates under a higher load. Heat pumps, electric heating, electric vehicle charging infrastructure. More heat during the day, more cold at night.

Ideal conditions for condensation.

What happens to water after it condenses

Water inside a transformer tank does not behave like a puddle on concrete. Its fate depends on many factors.

Some of the condensed water flows down the tank walls and enters the oil.

Transformer oil has a limited capacity to dissolve water.

At a temperature of around 20°C, this is in the range of several dozen ppm*.

*ppm = parts per million - equivalent to 1 milligram per liter of substance (mg/l) or 1 milligram per kilogram (mg/kg) of water.

Excess water migrates into the paper insulation. And electrical insulation paper acts like a sponge. Once absorbed, moisture is very difficult to remove from it.

Each percentage point increase in water content within the paper dramatically lowers its electrical withstand strength and accelerates aging. This is not a linear process. It's a curve that suddenly begins to spike.

Olej i wilgoć. Toksyczny duet

Olej transformatorowy pełni dwie kluczowe funkcje. Izoluje i chłodzi. Wilgoć uderza w obie naraz.

Rozpuszczalność wody w oleju transformatorowym silnie zależy od temperatury.

W temperaturze 20° C typowy olej mineralny jest w stanie rozpuścić około 30 do 50 ppm*

Przy 60° C ta wartość może wzrosnąć nawet trzykrotnie.

To oznacza, że w ciągu dnia olej wchłania wilgoć, a w nocy, gdy temperatura spada, nadmiar wody zaczyna się wytrącać.

Już niewielki wzrost zawartości wody w oleju powoduje spadek napięcia przebicia.

Przy poziomie 20 ppm napięcie przebicia może wynosić ponad 60 kV.

Przy 40 ppm spada często poniżej 40 kV.

To różnica, która w warunkach zwarciowych decyduje o przeżyciu lub porażce izolacji.

Zimą zdradliwy jest efekt pozornej poprawy.

Pobierając próbkę oleju w niskiej temperaturze, można uzyskać wynik wskazujący niższą zawartość wody rozpuszczonej. Część wilgoci znajduje się wtedy już w papierze lub w postaci mikrokropelek, których standardowe badania nie zawsze wychwytują.

Do tego dochodzi przyspieszone starzenie oleju.

W obecności wody i podwyższonej temperatury rośnie tempo reakcji chemicznych.

Tworzą się kwasy. Zwiększa się liczba kwasowa.

Olej traci swoje właściwości szybciej, niż przewiduje IEEE.

Oil testing in winter - 3 key methods

In winter, interpreting oil test results requires particular caution.

Three tools become crucial.

The first is determining water content using the Karl Fischer method.

The result must always be referenced to the oil temperature at the time of sampling and the transformer's operational history. A low ppm result from a cold sample does not mean moisture is absent. It may mean it has already left the oil.

The second tool is the analysis of Dissolved Gases (DGA).

Elevated concentrations of hydrogen and carbon monoxide in the absence of classic fault gases can be the first signal of insulation paper degradation caused by moisture.

The third element is observing trends, not single data points.

In winter, comparing results from different seasons is especially important.

Spikes in water content between summer and winter tell more than the absolute value.

Analysis of transformer oil allows for detecting the effects of water vapor condensation before it leads to degradation. This type of analysis helps identify insulation threats before winter failures occur. Photo CC: Freepik/13628

A transformer doesn't fail on the day it's tested. It tells a story that one must know how to read.

Paper insulation. The weakest link

At first glance, paper insulation seems like a secondary element.

It's not visible from the outside, it doesn't have parameters easily sold in a table, it doesn't impress like power or efficiency. And yet, it is very often what determines the real end of a transformer's life.

Electrical insulation paper ages by definition.

The process of cellulose depolymerization always occurs, even under ideal conditions.

The problem begins when moisture enters the game. Even a small increase in the water content of the paper acts as an aging catalyst. It is accepted that each doubling of the paper's moisture content significantly accelerates the degradation of cellulose chains.

What does this mean in engineering practice?

A drop in the mechanical strength of the windings. The paper ceases to serve as a stable spacer, and the windings lose their resistance to the electromechanical forces that appear during faults.

A transformer can operate correctly for years, until the first major grid test. Then, weak insulation doesn't fail spectacularly. It simply doesn't hold up.

Moisture is not a failure. It's a process.

A quiet killer that doesn't destroy immediately but systematically erodes the transformer's safety margin. And that's precisely why paper insulation is often the weakest link in the entire system.

Not because it is bad, but because it is merciless towards neglect.

Hermetic transformer or one with a conservator? Differences in moisture risk

In winter, a transformer quickly reveals which school of construction it comes from.

A hermetic transformer, by definition, limits contact with external air. The oil, gas space, and tank form a closed system. For moisture, this is a difficult situation. There are no revolving doors, no daily invitations for water vapor to enter. This is a huge advantage during the heating season.

But a hermetic transformer is not a magical vacuum capsule.

It's still steel, seals, and people doing the assembly. One poorly tightened connection, one gasket installed on a humid day, and moisture has a subscription for years. No dryer, no vent, no evacuation route. Silence, calm, and very long-term consequences.

Constructions with an oil conservator work differently.

Here, the oil volume is compensated by contact with atmospheric air.

This is a known, proven, and still common solution. However, in winter, it requires character.

An air dryer is not a decoration. It's the security guard at the gate. If it's asleep, moisture walks in without asking. And in winter, a dryer tires out faster than in summer. The gel loses effectiveness, indicator colors can lie, and every night's cooling cycle is another dose of moisture sucked inside.

In short, it looks like this. In a hermetic transformer, the design and installation are responsible. In a transformer with a conservator, operation is responsible. Physics is impartial, but very meticulous.

Therefore, the choice shouldn't start with the question which is better, but rather who will take care of it during winter.

We've already covered this topic in more detail here:

Transformer oil conservator – what it is, how it works, and when it is needed

Because water vapor doesn't have a favorite technology.

It simply checks where it can enter without knocking.

Common installation mistakes

Moisture is rarely the fault of the equipment itself.

More often, it's the result of small oversights:

✖ Opening the tank in humid conditions without protective measures.

✖ Leaving the transformer without oil for extended periods.

✖ Transport and open-air storage without protective covers.

✖ Lack of preheating before startup in winter.

Each of these elements seems harmless on its own. Together, they build the perfect environment for condensation.

Symptoms that are easy to ignore

The first signals of moisture presence are subtle:

✖ Slight changes in oil parameters.

✖ A gentle increase in the dissipation factor (tan delta).

✖ A minimal reduction in breakdown voltage.

They often end up in a periodic test report and remain there for years. Without any action (✖!) because, after all, the transformer is operating. The problem is that physics doesn't read reports.

How to reduce the risk of condensation

It's impossible to completely eliminate moisture.

But it is possible to manage it.

From a design perspective, it's worth opting for hermetic constructions.

Ensure appropriate oil volume reserves and solutions that minimize temperature fluctuations.

From an operational perspective, discipline is key.

Inspections, oil testing, responding to deviations.

In winter, the startup procedure becomes particularly important.

Gradual loading.

Avoiding sudden heating and cooling cycles.

A modern approach to MV transformers

Modern transformers are designed with such scenarios in mind.

Winter will always come.

Water vapor condensation doesn't make noise.

It doesn't flash red.

But it leaves a mark every season.

Conscious design, correct installation, and attentive operation allow you to erase that mark before it turns into a costly failure.

That's why the choice of a transformer is increasingly not just a decision about power and voltage.

It's becoming a decision about resistance to real operating conditions.

If you are considering purchasing or replacing a transformer, our current range of oil-immersed transformers has been designed precisely for scenarios where moisture, temperature variability, and seasonal load changes are the norm, not the exception.

They are complemented by dry-type transformers for where environmental conditions or the nature of the installation require a different approach.

We also invite you to the Energeks community on LinkedIn, where we regularly share knowledge from the power engineering industry.

SOURCES:

IEEE Power and Energy Society. Moisture effects in oil filled transformers.

CIGRE Technical Brochures on transformer insulation ageing.

IEC publications on insulating liquids and moisture management.

Cover Photo: Freepik/2148635097

There is a moment like that.

The transformer is already on its foundation, the oil is filled, everything looks solid, and someone half-jokingly says, "Well, that's one thing off our plate."

The unit is in place, voltage is present, the network is operational. At first glance, the matter is closed.

Except an oil transformer doesn't know the concept of "off our plate."

It is only just beginning its work.

And it remembers very well how it was installed, the conditions it operates in, how it was treated in the first months of service, and whether anyone even glanced at its documentation after commissioning.

When writing about the installation and maintenance requirements of oil transformers, we are not revisiting theory for theory's sake.

We are revisiting experiences from project implementations, whose origins almost always lie much earlier than it seems. Often in decisions that, at the moment of installation, seemed minor, obvious, or "done this way for years."

This article is for designers, contractors, investors, and maintenance personnel who want to have calmer heating seasons and fewer phone calls that start with the words, "something's up with the transformer."

To start, we'll talk about why installing a transformer is more than just correctly placing it on a foundation.

Next, we'll look at daily operation and what the transformer "tells" us through its behavior long before a failure occurs.

Finally, we'll return to maintenance, understood not as a checklist of tests, but as a way of thinking about a device that is meant to operate stably for decades.

reading time ~10 min

Installation of an oil transformer, or the moment you create your future or problems in installments

Installing an oil transformer is not just a "logistical operation."

It is not just unloading, placing, and signing a handover protocol. It is the moment when this device gets its character. Like a person at the start of their career. You either set them up for success, or later you'll be hauling them to workshops. Except this involves costly, time-consuming hassle.

A transformer pays you back for everything in failures.

A shoddily made foundation is a classic.

Concrete, sure. Rebar, sure. There was a design, sure.

The level was checked once because they were in a hurry. "It's almost level."

And here, the first red light goes on. An oil transformer is patient, but it's not naive. It remembers every millimeter of tilt, every makeshift solution, and every solemn "we'll fix it later." "Later" usually never comes.

At first, everything looks proper. Oil is filled, the tank stands, cooling works.

Except with even a slight tilt, the oil inside starts working differently than the manufacturer intended. Cooling becomes uneven, windings experience conditions no one predicted, and the transformer begins to age faster than it needs to. This isn't visible immediately. It shows up over time. Always over time.

Ventilation is another topic that often loses to reality.

An oil transformer doesn't like standing in a stuffy corner, even if it looks like a chunk of solid iron. A too-tight enclosure of a prefabricated transformer substation, a lack of sensible airflow, poorly chosen clearances. A classic. The first season is quiet. The second one too.

And then questions start about why temperatures don't match the theory.

If anyone wants to see how much operating conditions can change the rules of the game, it's worth revisiting the topic of transformer substations operating in heavy industrial conditions:

Otoczenie, montaż i projekt to jeden organizm, a nie trzy osobne tematy:

How not to burn a million? Principles for building a transformer substation for heavy industry

The environment, installation, and design are one organism, not three separate topics.

Grounding is a separate story

"It's connected, the resistance tested out, the protocol is done."

Everyone has heard that.

Except that grounding doesn't exist for paper. It's there to protect the transformer, the installation, and people. A poorly executed one will take its revenge during the first disturbances, overvoltages, or lightning strikes. And again, not always immediately. Most often, when nobody has time for it.

Installation is not a cost. It is an investment. An investment in whether you'll sleep soundly in five years or be nervously sifting through documentation wondering who signed off on the foundation back then.

Operation of an oil transformer, or: it's talking all the time, you just have to stop pretending not to hear it

An oil transformer in operation is not a "grey box."

It is not a device that either works or it doesn't. It talks non-stop.

Just not via email or alarms, until it absolutely has to. It talks through sound, temperature, smell, and behavior. The problem is that many people consider this background noise.

At first, everything is by the book.

It runs, voltages match, load is normal. And then the most dangerous phrase in power engineering appears: "It works, don't touch it." Hearing that phrase, an oil transformer starts planning its revenge, only spread out over time.

The first signal is often sound.

A soft hum is normal, everyone knows that. But a change in the sound's character is not normal. A deeper tone, a metallic resonance, irregularity. This isn't "the charm of an old network." It is information. Ignored information.

Then come the temperatures. Someone glances at the readings and waves it off.

"Summer, it's warm, higher load." Sure, it happens.

But if the transformer regularly runs warmer than before, it's not a whim of the weather. It's a signal that something in the operating conditions has changed. Cooling, oil, ventilation, surroundings. Something is off.

The smell of oil near the transformer is something many people only notice when it's already really strong.

A pity. Transformer oil can tell you a lot much earlier. A change in smell, color, clarity. These are trivialities only for someone who doesn't want to see them. For the transformer, it's a full-fledged language of communication.

Oil leaks are one of those signals that everyone sees, but many pretend it's "nothing serious." A drop here, slight dampness near a gasket, a trace on the oil sump.

At this moment, the oil transformer isn't screaming. It's just raising its hand and calmly saying that something is no longer sealed. Ignoring such small things is a straight path to accelerated insulation aging, cooling problems, and costs that always appear at the least opportune moment.

That's why if someone wants to understand why oil leaks are not a cosmetic issue but a real warning signal, it's worth checking out the separate article dedicated to this topic:

Oil leaks in transformers – do not ignore these signals

There you can see in black and white that oil doesn't escape without reason, and every leak is information about the state of the transformer, not just the state of a gasket.

Operation is also about loading.

An oil transformer can handle overloads because it was designed for that.

But it handles them short-term. Permanently operating at the power limit is not proof that "we managed with a reserve." It is a very consistent and very predictable way of shortening the device's life.

An oil transformer doesn't spring surprises. It is predictable to a fault.

You just have to want to listen, not assume that if the light is green, the issue doesn't exist.

Maintenance of an oil transformer, or why revisiting the beginning saves the future

Maintenance has terrible PR.

It's associated with paperwork, costs, and an obligation that can always be pushed to later. Preferably to the next quarter. Or the next year.

Meanwhile, for an oil transformer, maintenance is the purest form of ensuring longevity. Without it, even the best-designed device starts showing signs of fatigue sooner.

And here it's worth going back to basics for a moment.

To the moment when the transformer was installed and commissioned. Because very often, what we call an operational problem today is not a new failure or some malicious fault of the equipment. It is a consequence of how the installation was done at the start.

An oil transformer doesn't change the rules mid-game. It simply delivers on what it was given at the beginning.

If something was rushed during installation, if something was done by eye, if the handover was quick because the deadline was looming, then maintenance will show it sooner or later. Temperature changes, unusual sounds, faster oil aging, cooling problems. These aren't new phenomena.

They are the effects of earlier decisions, just stretched over time.

Oil testing is the best example here.

It's not a manufacturer's whim or a standard's invention. It is the simplest and cheapest way to look inside a transformer without taking it apart. Physicochemical parameters, dissolved gas content, oil moisture level say more than many a visual inspection.

And yet, in practice, tests are done irregularly or only "for handover," as if the oil stopped working after the protocol was signed.

Seals, accessories, electrical connections, and grounding also age.

A transformer doesn't stand in a sterile lab. It operates under variable temperature, humidity, vibration, and pollution. Every season adds its share. A lack of regular inspection means small problems have time to grow. And then everyone is surprised that something that seemed cosmetic suddenly becomes an emergency issue.

That's why returning to the installation stage when operational and maintenance questions arise is one of the best things you can do.

Checking whether the foundation truly met the assumptions, whether ventilation works as intended, whether grounding was executed according to the craft, not just according to the protocol. This often explains more than hours of analyzing current parameters.

The specific stages that have a real impact on how the transformer behaves later in daily operation, and why some units work quietly for years while others start acting up much sooner, are described here:

Power transformer installation – a comprehensive checklist

The most important thing is the approach

Maintenance is not a checklist to tick off or an obligation imposed by standards.

It is a way of thinking about a transformer as a device that should operate stably for twenty, thirty years. Every test, every note, and every review shorten the list of surprises.

An oil transformer does not spring surprises.

It is predictable to a fault. If something starts happening, it is very rarely a coincidence. Usually, it's a response to the conditions it has been given. Except the response comes with a delay, at a time when everyone is already convinced the matter was closed long ago.

If you want smooth operation, you need to honestly look at the beginning and regularly check in along the way.

An oil transformer doesn't require flattery or gifts. It requires attention.

And attention pays back with interest, most often when others are busy putting out fires.

Don't stop at the start

An oil transformer is not a matter to "tick off." It is a piece of infrastructure that either works quietly for years or regularly reminds you of itself at the least opportune moments.

Transformer installation, operation, and maintenance are not three separate worlds.

It's one story, written from the day the transformer was placed on its foundation. Every decision at the beginning works in the background later. Either for you or against you. An oil transformer doesn't create drama. It simply adds up the facts.

That's why if you're planning an investment, a modernization, or simply want peace of mind in operation, it's worth looking broader than just the moment of purchase.

At Energeks, we have been working with oil transformers in real grid, industrial, and infrastructure conditions for years. Our offering includes both oil-filled and dry-type (resin-insulated) units, selected for specific operating conditions.

Everything is in the EcoDesign Tier 2 class, with full documentation and certificates:

You can find the current transformer offering here.

Thank you for taking the time to read this text.

If even one thought stayed with you, it means it was worth it. And if you want to stay updated, I invite you to Energeks on LinkedIn.

Winter is when everything comes to light.

For most of the year, the installation works correctly.

The oil transformer has a power reserve. Voltage stays within limits. There are no complaints, no alarms, no phone calls from users.

And then the first cold wave hits, and suddenly something no one planned for begins to happen.

Flickering lights. Notifications about voltage being too low.

Heat pumps that shut down exactly when they are needed most.

In the background, a transformer that according to the documentation "should handle this," but in reality is operating on the edge of stability.

This isn't a story about faulty technology.

It's also not a tale of user errors.

It's a story about the collision between a new way of using energy and infrastructure that was designed under completely different circumstances.

Heat pumps have changed the network load profile.

They did it quickly, massively, and often without a parallel shift in thinking about medium voltage transformers. The annual energy consumption still adds up. The nameplate power looks reasonable.

And yet, in winter, voltage drops, alarms, and questions arise that are difficult to answer in a single sentence.

Why do problems start precisely when the temperature drops below zero?

Why does an oil transformer, which operates calmly in summer, react completely differently in winter?

And why does the classical approach to power rating selection stop being sufficient in a world of mass-scale heat pumps?

This article was created to organize these phenomena.

Without scaremongering about failures. Without oversimplifying the physics. Without shifting blame to one side.

We will show what the load generated by heat pumps really looks like during the heating season, how an oil transformer reacts to it, where voltage drops occur, and why they are not random.

And what can be done before the only answer becomes a costly modernization.

If you are responsible for the network, a project, a facility, or investment decisions, this text will help you look at the problem from a broader perspective. One that considers both the technology and the real operating conditions.

Reading time: approximately 13 minutes

How heat pumps really stress the grid in winter

In summer, a heat pump is almost invisible to the grid.

It operates sporadically, mainly for domestic hot water. Its momentary power draw is moderate, and its load profile blends into the background of other consumers. An oil transformer sees it as just one element among many in the landscape.

In winter, the situation changes radically.

The heat pump stops being an add-on. It becomes the primary source of thermal energy, and therefore a device operating for long periods, intensively, and often in sync with hundreds of other similar installations on the same network.

One key word here is: momentary power.

Project documents most often analyze annual consumption. The kilowatt-hours add up, the SCOP coefficients look good, and the energy balance seems reasonable. The problem is that a transformer doesn't see kilowatt-hours. It sees amperes, here and now.

And in winter, "here and now" looks different than in summer.

When the temperature drops below zero, the demand for heat increases. The heat pump's compressor runs longer and more frequently. Its momentary efficiency drops, so generating the same amount of thermal energy requires more electrical energy. Add to this the defrost cycles of the evaporator, which generate short-term but repetitive power draw spikes.

On the scale of a single house, this still looks innocent.

On the scale of a housing estate, a facility, or an area supplied by one MV/LV transformer, the cumulative effect begins.

Everyone heats at the same time.

The coldest days mean peak load occurs at exactly the same morning and evening hours. The grid has no time to "breathe," and the transformer enters prolonged operation near the limits of its thermal and voltage capabilities.

This is where the first paradox appears, which often surprises investors and designers.

An oil transformer may not be overloaded in terms of power, yet it can still cause problems.

Why?

Because the problem isn't always exceeding the nameplate rating. Often, it is the voltage drop resulting from the nature of the load.

Heat pumps, especially inverter-driven ones, are not linear loads. Their current draw changes dynamically. At low temperatures, the current on the low-voltage side increases, and every additional ampere means a greater voltage drop across the transformer's impedance and the supply line.

In summer, the same transformer operates at a higher secondary voltage, lower current, and with a large regulatory margin. In winter, that margin disappears.

If we add to this networks designed decades ago with the assumption that the main loads would be lighting, appliances, and occasional electric heating, the picture becomes clear.

This isn't a failure.

This is a change in boundary conditions that the infrastructure simply wasn't designed for.

In the next part, we'll take a closer look at how an oil transformer reacts to such a load from a physics perspective. Without myths about "overheating in winter" and without magical explanations. Only what really happens in the core, windings, and oil when the grid starts breathing frost.

What really happens inside an oil transformer during a frost

From the outside, a transformer looks the same in July and January.

The same enclosure. The same oil. The same parameters on the nameplate.

The difference begins on the inside.

An oil transformer does not react to winter in an intuitive way. The low ambient temperature is not a problem in and of itself. Quite the contrary. Cooling is more efficient then. The oil dissipates heat to the surroundings more easily, and the thermal headroom seems larger than in summer.

And it's right here that a false sense of security is born.

Because in winter, the problem is not the transformer's temperature. The problem is voltage and current.

When the load on the low-voltage side increases, the current in the windings rises. Along with it, copper losses—proportional to the square of the current—increase. This phenomenon is well known and accounted for in design.

But simultaneously, the voltage drop across the transformer's impedance increases.

Every transformer has its short-circuit impedance. This is not a flaw or a random feature. It is a design parameter that determines how the transformer will behave under load and during a short-circuit.

The greater the current, the greater the voltage drop.

In summer, this drop is hardly noticeable. In winter, under prolonged load close to peak, it begins to be felt by the connected equipment.

Heat pumps are particularly sensitive to this.

The inverters controlling the compressors have their own lower voltage thresholds. When the voltage drops too low, the electronics react immediately. First, it limits power. Then it goes into an alarm state. Finally, it shuts the device down.

From the user's perspective, this looks like a random failure.

From the transformer's perspective, it's a logical consequence of operating under conditions the network wasn't designed for.

A further domino effect occurs.

When some heat pumps shut down due to low voltage, the load temporarily decreases. The voltage bounces back up. The devices attempt to restart. The inrush current appears simultaneously at many points in the network.

The transformer receives a series of load impulses that further destabilize the voltage.

This is not an overload in the classical sense.

It is an operational instability resulting from the nature of the loads and their synchronization.

This often leads to a question about the transformer's tap changer.

If the voltage is dropping, maybe it's enough to raise it.

Sometimes this helps. Sometimes it just shifts the problem elsewhere.

Raising the secondary voltage increases the margin for heat pumps, but it also raises the voltage during hours of lighter load. This can lead to exceeding permissible voltage levels for other consumers. Especially where the network is short and has low impedance ("stiff").

A transformer does not operate in a vacuum. It is a part of a system.

If the system has changed, the transformer begins to reveal its weak points.

In the next part, we will examine why classical methods for selecting transformer power ratings are becoming insufficient in a world of mass-scale heat pumps and what warning signs appear long before the first winter alarm.

Why the classical power rating selection method stops working

For years, everything was logical and predictable.

Selecting a transformer was based on installed power, simultaneity factors, and annual energy consumption. Add a small safety margin—sometimes 10 percent, sometimes 20. In most cases, that was enough.

Because the loads were passive and spread out over time.

Lighting, motors, household appliances. Each had its own operating rhythm. Even if several devices turned on at the same time, the scale of the phenomenon was limited.

Heat pumps have changed this order.

Not because they are faulty. Not because they draw "too much current." They changed it because they introduce a strong temporal correlation of load.

When it gets cold, they all want to run. At the same moment. For many hours without a break.

Classical simultaneity factors begin to lie. On paper, everything adds up. In reality, the network sees nearly the full load for a long time, not short inrush peaks.

Another element, often overlooked in analyses, comes into play.

A transformer is selected based on active power. Winter problems very often start with reactive power and the nature of the current.

The inverters in heat pumps improve the power factor (cos φ), but they don't completely eliminate current distortions. Harmonics, especially lower-order ones, increase the effective current without a proportional increase in active power. The transformer sees a greater current load, even though the energy meter doesn't show it directly.

This is another reason why "the kW adds up," but the voltage drops.

In practice, this means a transformer selected perfectly according to the old methodology can operate in winter under conditions no one considered. Not as a short-term exception, but as a new norm.

The first warning signs appear early.

They are not failures or protection tripping.

They are subtle symptoms that are easy to ignore.

Voltage at the lower limit of the norm in the morning hours. An increased number of voltage alarms in the inverters. User complaints that "something sometimes flickers." Logs from monitoring systems showing long periods of high load without distinct peaks.

This is the moment when the network is still working. But it has no margin left.

Many investment decisions are made only after the first serious problem appears. In winter, under time pressure, user dissatisfaction, and weather conditions. This is the worst possible moment for a calm analysis.

That's why, in the next part, we will move on to what can be done earlier.

What diagnostic tools truly provide answers, how to distinguish a power problem from a voltage problem, and when a transformer is actually undersized, versus when it's simply poorly matched to a changed network.

What to check before a real problem begins

In winter, the network doesn't forgive illusions.

If the first signs of instability appear, it means physics has already sent a warning signal. It's just not screaming yet.

The most common mistake is trying to answer with a single parameter. Transformer power rating. Cable cross-section. Protection setting. However, winter problems rarely have a single cause.

It starts with measurements. But not the kind that last a few hours on a random day.

A seasonal picture is needed.

Load profiles from summer and winter periods. At least several weeks of data. Preferably with fifteen-minute or shorter resolution. Only then can you see whether the load is impulsive or continuous. Whether the voltage drops slowly or collapses sharply at specific times.

A transformer rarely lies. It simply shows what the network is doing to it.

The next step is to analyze voltage at several points in the low-voltage network, not just at the transformer terminals. The voltage drop at the transformer might look acceptable, while at the end of a supply line it exceeds permissible limits.

This is especially important where heat pumps have been added to existing buildings without upgrading lines and distribution boards.

It's also worth looking at what happens with reactive power and effective current.

If the current rises faster than the active power, it's a signal that the transformer is being loaded in a way that isn't visible in standard energy consumption summaries. Harmonics, phase imbalance, and uneven switching of loads can eat up the margin faster than you think.

A frequently overlooked element is voltage regulation.

Transformer tap settings are often based on historical conditions, from before the facility's modernization. Changing one tap step can improve the situation in winter, but only if preceded by an analysis of voltages across the entire load range. Otherwise, the problem will shift to summer.

This brings us to an important distinction.

Not every winter problem means the transformer is too small.

Sometimes its power rating is sufficient, but it's operating in a network with too high impedance. Sometimes it's correctly sized, but the load is too strongly time-correlated. And sometimes the limit has indeed been exceeded, but no one wanted to call it by its name earlier.

A good diagnosis allows you to choose the right tool.

Upgrading the transformer is one of them. But it's not always the first, nor the most sensible, option.

We've covered this topic in more detail in a separate article:

Renovate or replace? The last chance for your transformer!

In the next part, we'll show which action scenarios are realistic in practice. From the simplest operational adjustments, through changes in network configuration, to investment decisions that only make sense when they are based on data, not winter panic.

How to design and operate transformers in a world of heat pumps

The biggest change in recent years hasn't been about the transformers themselves.

It's about the way we think about the network.

For decades, design was an attempt to predict averages. Average consumption. Average peaks. Average customer behavior. This model worked as long as appliances had different rhythms and didn't respond en masse to the same stimulus.

Heat pumps respond to temperature. Simultaneously. Without negotiation.

This means the network must be designed for extreme scenarios, not just for the annual balance.

A transformer ceases to be merely a source of power. It becomes an element of voltage stabilization under conditions of prolonged load. This changes the selection criteria.

Increasing importance is placed not only on the nameplate rating, but on the transformer's impedance, its voltage regulation characteristics, and its cooperation with the rest of the infrastructure. Two transformers with the same power rating can behave completely differently in winter if they have different short-circuit impedances or different regulation capabilities.

Operation also requires a new approach.

Instead of reacting to failures, it's worth observing trends. Are minimum voltages dropping year by year? Is the operating time under high load lengthening? Is the number of power electronic loads growing faster than assumed?

These are signals that appear long before a crisis.

A well-designed network with oil transformers is not afraid of winter. It has a margin. It has flexibility. And above all, it has the awareness that the way energy is used has already changed and will not return to the state before mass-scale heat pumps.

Therefore, the key question today is not: will the transformer survive this winter?

The question is: will it still operate stably in five years within a network that is increasingly reactive to weather, automation, and simultaneity?

If the answer isn't clear, the best time to act is now. Calmly. With data. Without winter panic.

Because winter will always come. And the network should be ready for it before it gets truly cold.

In the end, it's worth putting a period in a place that doesn't close the topic, but opens up possibilities.

Today, the oil transformer is no longer a passive piece of infrastructure.

In the reality of mass-scale heat pumps, it becomes a tool for conscious management of voltage, losses, and network stability. A well-chosen, properly configured unit that meets current Ecodesign Tier 2 requirements — like the MarkoEco2 from Energeks — can regain the margin that is most sorely missed in winter. Not through oversizing, but through better power quality, lower load losses, and a true match for modern operating profiles.

Our current transformer offering has been designed precisely for such scenarios, where the network must operate stably not only today but also in the heating seasons to come.

It includes both oil transformers, proven in demanding operating conditions and resilient to prolonged winter loads, and dry-type transformers, chosen where fire safety, environmental conditions, or indoor installation are of key importance.

In both cases, the starting point is the same. Voltage stability, low losses, compliance with current energy efficiency requirements, and a genuine fit for modern load profiles—where heat pumps are no longer the exception, but the norm.

Thank you for your time and attention. If you are interested in such analyses, real project experiences, and thoughtful conversations about how the energy sector is changing from within, we invite you to our community on LinkedIn.

Sources:

International Energy Agency (IEA)

https://www.iea.org/reports/the-future-of-heat-pumps

ENTSO E

https://www.entsoe.eu/publications/system-development-reports/

Autumn-winter morning.

Dawn is just beginning to filter through the pine needles. On a white meadow, a transformer station stands alone, yet alive.

A light mist rises from the tank, like a breath in the frosty air. The engineer beside it looks up at the silvery vessel above the transformer. It is the oil conservator.

A metal safety shell that many mistake for an unnecessary accessory.

The question keeps coming back like a boomerang: does a transformer need an oil conservator?

In practice, the choice between an oil-immersed transformer with a conservator and a hermetically sealed design depends on the operating environment, load profile, diagnostic strategy, and requirements of the distribution system operator (DSO).

This article gathers both textbook knowledge and field experience in one place, clarifying concepts and showing the technical implications of each approach. We do not promote either option; instead, we compare them fairly so that the decision can be made predictably over the transformer’s entire life cycle.

At Energeks, we work with medium-voltage substations, transformers, and switchgears in diverse climatic and operational conditions. We see where hermetically sealed designs shine with simplicity and minimal maintenance, and where an additional compensating volume and traditional diagnostics provide operational peace of mind. This text distills those lessons into practical criteria.

The decision is not about conservator versus modernity.

It is about context versus coincidence.

A properly selected transformer reduces risk, costs, and the temperature of emotions during acceptance.

Who is this article for?

For designers, contractors, operators, and investors who want to select a transformer consciously, based on location, load profile, and maintenance policy. After reading, you will gain the knowledge needed to make better decisions, understand when an open oil circulation system makes sense, when a hermetically sealed unit is sufficient, how to plan diagnostics and maintenance, and how to avoid the most common mistakes.

Agenda

Oil conservator in a transformer: what it is and how it works

Transformer with an oil conservator: when to use it

Transformer with an oil conservator: when it is necessary

Selecting an oil-immersed transformer: service and operational best practices

Maintenance comparison: hermetically sealed transformer vs. transformer with conservator

Reading time: approximately 10 minutes

1. Oil conservator in a transformer – what it is and how it works

Imagine a transformer as the powerful heart of the electrical grid.

It pulses with current, responds to load fluctuations, heats up, and cools down. And like any heart, it needs space to beat in rhythm. For a transformer, that space is provided by the oil conservator – a modest cylindrical tank mounted above the main vessel.

It absorbs changes in the volume of oil as it expands in the heat and contracts in the cold.

Technically speaking, the oil conservator is a compensating reservoir connected to the transformer tank by a pipe through which the oil can flow freely. Inside, there is an air space, and between that space and the atmosphere operates a breather filter, also known as an air dryer – a small device filled with silica gel that removes moisture from the incoming air.

This setup allows the transformer to “breathe” without drawing in water, dust, or oxides.

It protects both the paper insulation and the oil from humidity, preventing premature aging.

If this description reminds you of anatomy, that is intentional.

A transformer with an oil conservator truly behaves like a living organism: during operation, it exhales heat and gases, and when it cools down, it inhales air. Without a conservator, it would also absorb moisture – and that moisture is to insulation what rust is to steel.

So, when someone asks “What is an oil conservator in a transformer?”, the answer is simple: it is a system that protects the oil from moisture and oxidation, extending its service life and maintaining stable electrical properties. In practice, the conservator often determines whether the oil will last thirty years or ten.

But its function doesn’t end with breathing.

The conservator also serves as a diagnostic indicator. It is equipped with a float-type oil level gauge, showing how the oil volume changes depending on temperature and load.

A sudden drop in oil level may indicate a leak, overheating, or an early sign of failure. For an experienced technician, this gauge is like the patient’s pulse – a small movement can reveal a great deal.

In higher-power units, the conservator also works together with a Buchholz relay, which detects gases generated by winding faults.

Thanks to this, the system can alert operators to a developing issue before it becomes critical.

In short: the conservator is the breath and the memory of the transformer.

And if someone asks, “When is a transformer with a conservator necessary?”, one might half-jokingly say: whenever you want your transformer to have healthy lungs and a long life.

A conservator is not always necessary

It is important, however, to maintain an engineering sense of balance.

A conservator is not a magical cure-all, and its absence does not signify a flaw in design.

Modern sealed transformers are not an inferior version; they represent an entirely different design philosophy.

Instead of the classic "breathing" provided by a conservator, their tank is completely sealed.

The changes in oil volume are compensated for by flexible corrugated walls or an internal elastic diaphragm.

This means the oil has no contact with the outside air whatsoever – it doesn't require a breather filter, it cannot absorb atmospheric moisture, and there is no need to monitor silica gel.

This solution proves its worth in environments that are clean and predictable: in indoor switchgear rooms, containerized substations, energy storage sites, and modern industrial facilities.

A sealed transformer requires less additional equipment, making it less susceptible to operator error and simpler to maintain. For many investors, this is a significant advantage – fewer inspections, fewer potential points for leakage, and lower operational costs.

Therefore, it is incorrect to claim that a transformer with a conservator is "better," and a sealed one is "worse."

They simply have different temperaments.

One is lik

e a marathon runner – built for endurance and resilience in changing conditions. The other is like a sprinter – compact and precise in a controlled environment.

A good engineer does not choose out of habit, but based on context: temperature, humidity, location, and the device's duty cycle.

So, if someone tells you a conservator is "mandatory," it's wise to smile and ask:

What is your actual operating environment?

Perhaps, instead of needing "lungs," what you truly need is a well-sealed construction that will operate reliably for its full 25-year lifespan in hermetic tranquility.

In the next part of this article, we will examine this with technical curiosity:

Where a transformer with a conservator truly makes sense.

Where a sealed design is the more rational choice.

We will compare how the two designs handle temperature, moisture, and oil aging.

We will also explore the real-world advantages of a conservator tank in practice and answer the question of when it is worth choosing one, and when a simpler sealed transformer will be the better option.

Because in engineering, as in life – more is not always better.

2. Transformer with an oil conservator – when to use it

The question “when to use a transformer with an oil conservator” is far from academic. In practice, the decision depends on the operating environment, the load profile, and the maintenance philosophy of the facility.

To clarify: the conservator is a compensating tank connected to the transformer vessel, allowing the oil to “breathe” as its temperature changes. The air entering from the outside passes through a silica gel breather, which captures moisture to prevent the degradation of insulation and the loss of dielectric properties in the oil.

Modern standards – including PN-EN 60076-1 and IEC 60076-7 – do not mandate a specific design type. Instead, they emphasize that the choice depends on operational conditions.

The selection criteria and the influence of environmental factors are discussed in detail in: IEC 60076-7: Loading guide for oil-immersed power transformers

And this brings us to the core of the matter: a conservator is neither better nor worse than a sealed design. It is simply a different method for managing the thermal expansion of the insulating oil.

Environments where a conservator makes sense

So, when is the environment favorable for a conservator?

Typically, in applications with significant temperature fluctuations—exceeding 50–60 °C annually—or where the thermal load changes dynamically. In these cases, the conservator acts as a pressure and temperature buffer, reducing mechanical stress on the main tank and enhancing the overall thermal stability of the system.

This solution is still commonly found in higher-power transformers (above 2.5 MVA) or those with on-load tap changers (OLTC), where easy diagnostic access and the use of classic Buchholz gas protection are important.

Furthermore, in locations with high humidity or significant microclimatic variability, a conservator can be beneficial—it helps limit moisture ingress into the system and slows down the oil aging process.

However, it must be emphasized: such a system requires oversight. If the breather filter is not regularly serviced, it can itself become a source of contamination, and its advantages are quickly lost.

Where a conservator is not needed

For the majority of modern installations, there is no longer a necessity to use a conservator.

Sealed transformers, with their corrugated tank walls or flexible diaphragms, compensate for oil volume changes without any contact with the external air. This reduces the need for servicing, eliminates breathers, and minimizes the risk of contamination. This is why in containerized substations, urban medium-voltage switchgear, at energy storage sites, PV farms, or within e-mobility infrastructure, the sealed design has become the default choice.

This is not a matter of trends, but of the operating environment.

In a temperate climate, with limited humidity and stable temperatures, a conservator offers no real advantage—it merely adds more components that require monitoring and maintenance.

In many contemporary projects, a standard transformer with a conservator is not so much an option as it is superfluous.

So when does a conservator come back into play?

When a project demands high thermal stability, easy diagnostic access, and compatibility with a Buchholz relay, the conservator remains a justified solution—not out of habit, but due to physics.

In high-power transformers, where the oil volume is measured in thousands of liters, temperature changes cause significant pressure differentials. The conservator then acts as a dampener—it absorbs the excess fluid during heating and returns it during cooling. It stabilizes internal pressure, relieves stress on seals, and slows the aging rate of the insulation.

The second area is diagnostics. A system with a conservator allows for easy visual or SCADA-sensor monitoring of the oil level, as well as simple oil sampling for Dissolved Gas Analysis (DGA). DGA is a crucial tool for assessing the condition of the paper-oil insulation, and in a sealed transformer, it can be more complicated as it may require breaking the tank's seal and risks exposing the sample to air.

The third aspect is gas protection—the Buchholz relay.

Mounted in the pipe between the main tank and the conservator, it reacts to gases generated by internal overheating or minor winding faults. Its operation is purely mechanical, requiring no external power—which is why it remains one of the most reliable protections for oil-filled transformers. In sealed transformers, where there is no gas cushion, the Buchholz relay simply has no place to function.

These requirements are found mainly in medium and large power network transformers, municipal infrastructure, and transmission substations, where durability, predictability, and rapid diagnostics are valued over absolute maintenance-freedom.

In these cases, the conservator is not a relic, but a functional element of the safety architecture.

In short then:

When to choose a transformer with a conservator?

When the project demands superior thermal stability and pressure management.

When full diagnostic control and easy oil sampling for DGA are required.

When compatibility with a classic, highly reliable Buchholz relay protection system is necessary.

And when to opt for a sealed transformer?

In the majority of modern projects located in temperate climates.

Where the top priorities are simplicity, cleanliness, and minimal maintenance.