2025. The year theory stopped being enough

The year 2025 did not bring a single, great technological breakthrough.

No miracle material appeared. Physics didn't change. No new law of electrical engineering was discovered.

Instead, something much less spectacular but far more painful happened.

Reality started to test assumptions.

Those that had worked "well enough" for years suddenly stopped holding up.

Projects copied from previous years began to fall apart during the execution phase. Budgets that were supposed to balance on paper started to leak in areas previously considered safe. Schedules based on standard solutions had to be corrected mid-game.

And it quickly became apparent that the transformer was no longer just part of the background.

In 2025, the transformer became a topic of conversation on construction sites, in design offices, and at investors' tables. It appeared in questions about energy losses, compliance with Ecodesign Tier 2, real operating costs, dimensions, logistics, and acceptance procedures. Increasingly, not as an isolated problem, but as an element that could decide the success of an entire project.

This was the year theory was invited onto the construction site. And it didn't always come out unscathed.

This text is not a product summary. It is a summary of experiences.

It is an attempt to gather conclusions from a year that very effectively separated convenient assumptions from true ones. It is written with designers, contractors, and investors in mind who don't want to enter 2026 relying on memory or shortcuts. Only with greater peace of mind and better insight.

Because if 2025 taught the energy industry anything, it's that not everything that worked yesterday works just as well tomorrow.

We didn't ask which transformer is the best. We asked which one stopped being a problem.

We are not creating a ranking. We are not selling promises. We are looking at the tensions that emerged in 2025 between regulations, physics, and budgets. We examine where theory diverged from practice and what decisions began to win out in real projects.

This is a story about losses that suddenly started to matter.

About power that stopped being just a number in a table. About documentation that could either save or stall an investment. And about why, in 2026, the question is no longer "what is the most powerful," but "what provides predictability."

Reading time: ~11 minutes

Ecodesign Tier 2 Stopped Being Theory. It Became a Reality Filter

Just a few years ago, Ecodesign Tier 2 was mainly a future concept in the industry.

Something that would "come into effect," "be mandatory," "need to be considered." In 2025, this mindset stopped working.

Tier 2 ceased to be a clause in a directive. It became a very practical filter through which real projects either started to pass or began to fail.

On paper, everything looked simple.

Lower no-load losses, better efficiency, compliance with the regulation. In practice, 2025 showed that not every transformer that "almost meets" the requirements actually meets them in the context of a specific installation. Differences of a few watts in no-load losses, previously ignored, started to matter. Not because everyone suddenly fell in love with efficiency.

But because energy stopped being cheap background noise and became a real cost.

In many projects, Tier 2 exposed old design habits.

Selecting a transformer "by eye," based on previous projects, stopped being safe. Solutions that had passed acceptance for years without major questions began to raise doubts in 2025. Additional queries, clarifications, and corrections appeared. Sometimes at the design stage, sometimes during execution, which always hurts more.

The problem wasn't the regulation itself.

It was that Tier 2 forced a confrontation with the transformer's actual operating profile. No-load losses, previously treated as a "fixed and negligible" cost, began to be analyzed on a yearly scale, not just at the moment of acceptance. In installations where transformers operate at low load most of the time, it suddenly turned out that these very losses determined the economics of the solution.

2025 also showed that not every project is equally ready for Tier 2.

In new installations, it was easier to incorporate the requirements from the start. In modernizations and expansions, the situation was often more complicated. Space constraints, existing infrastructure, and previous design assumptions could clash with the new requirements in a very unpleasant way.

Added to this was the issue of availability.

Last year, the market felt very clearly that a Tier 2-compliant transformer is not always an "off-the-shelf" item. Lead times, logistics, and delivery planning began to have a real impact on investment schedules. Projects that didn't account for this in advance often had to make up for lost time in other areas or postpone deadlines.

Another interesting phenomenon was how the narrative around Tier 2 changed.

The question "do we have to?" disappeared, and the question "how to do it sensibly?" appeared. Conversations increasingly focused not just on meeting the standard, but on the consequences of choosing a specific solution.

How will it affect losses in the long term? What about servicing? And future load changes?

In this sense, Ecodesign Tier 2 did the industry a favor. It didn't simplify life.

But it forced thinking in holistic, not just formal, terms. And it quickly became clear that in 2026, Tier 2 will no longer be a topic for discussion. It will be the starting point.

We wrote about no-load losses in Tier 2 and their translation into specific financial figures here—it's worth familiarizing yourself with this knowledge:

No-load losses in Tier 2 transformers. How to calculate the real cost?

Nameplate Rating Versus Real-World Usage

If one assumption was tested with particular harshness in 2025, it was the belief that a transformer's nameplate rating tells you everything about it.

For years, it was treated as a safe anchor. There's the number. There's the margin. There's peace of mind. The problem is that reality very rarely operates according to the same chart.

In 2025, many projects painfully collided with the fact that a transformer doesn't operate in a vacuum. It operates over time. In daily cycles. With seasonal patterns. In an environment of loads that changed their character faster than most design assumptions.

The classic mistake looked innocent. "Let's take a larger transformer, it will be safer."

Or the opposite. "The load profile looks light, we can reduce the power." On paper, it all added up. In the spreadsheet too. On the construction site and in operation, problems began.

Oversizing in 2025 ceased to be neutral.

A transformer operating most of the time at a very low load generates no-load losses regardless of whether it's delivering power or not. With rising energy costs, this became noticeable not after a year, but after a few months. Investors, who not long ago would have waved it off, began asking questions. Where do these numbers come from? Why don't the bills look as projected?

On the other hand, problems with undersizing emerged.

Especially where the load profile was based on historical data that didn't account for changes on the consumer side. Heat pumps, electric vehicle chargers, inverters, irregular operating cycles. All this meant that momentary overloads, starting currents, and short-term power peaks began occurring more frequently than anticipated.

In 2025, many people truly saw, for the first time, the difference between the nameplate rating and the transformer's actual behavior over time. A transformer can have a power reserve, yet operate under conditions that cause excessive heating.

It can formally meet requirements, yet practically shorten its lifespan. It can "manage," but at the cost of losses and operational stress.

A common source of the problem was a simplified approach to the load profile.

The average power over a day or month says little about what happens at specific moments.

And it is precisely these moments that determine how the transformer behaves. Short but intense loads can do more damage than stable operation at a higher level.

The year 2025 also showed that the conversation about a transformer's power cannot end with the number in its name. Increasingly, questions about the nature of the loads, their variability over time, and plans for installation development came to the fore. Designers began returning to investors more often with questions previously deemed unnecessary.

What will the load look like in two years?

What will change after expansion?

Which scenarios are realistic, and which are only theoretical?

All of this meant that in 2025, selecting a transformer's power rating stopped being a "just-in-case" decision. It became a strategic decision. One that must consider not only what is today, but what is very likely tomorrow.

And that is precisely why, heading into 2026, fewer and fewer people ask which transformer has the highest power rating. More and more ask which one best fits the actual way it will be used.

And that is a change that makes a huge difference.

Energy losses stopped being abstract. They started to cost, truly

For many years, transformer losses were one of those topics everyone was aware of, but few truly calculated. Sure, they appeared in documentation. Sure, they were listed in catalog sheets. But in practice, they were treated as a background cost. Something that "just exists" and doesn't require deeper attention.

The year 2025 ended this comfortable stage.

At the moment when energy prices stopped being a stable reference point and began to fluctuate in reality, transformer no-load losses stepped out of the shadows.

And they did so in a very unpleasant way. It suddenly turned out that differences which previously seemed cosmetic began to be noticeable in the operational budget over the course of a year.

The biggest surprise for many investors wasn't the load losses. Those are intuitively associated with the device's work. The real discovery turned out to be the no-load losses. Constant. Independent of the load. Present always, even when the transformer is mostly just "waiting."

In installations with uneven or seasonal operating profiles, it was precisely these losses that began to play the leading role. A transformer that was formally well-matched spent a large part of the year operating far from its optimal point. And energy was leaking away. Day after day. Without noise. Without alarms. Without visible symptoms, except for one thing that cannot be ignored: the bill.

2025 was also the moment when more and more projects began to be analyzed in terms of Total Cost of Ownership (TCO), not just the purchase price. TCO stopped being a trendy acronym. It became a defensive tool. Investors began asking not what a given transformer would cost at the moment of acceptance, but after five, ten, fifteen years of operation.

This changed the dynamic of conversations.

Cheaper solutions began to lose in the long-term horizon. A difference of a few percent in efficiency, previously considered a detail, in the new calculations could determine the profitability of the entire investment. And interestingly, these conversations increasingly took place not at the tender stage, but after the first year of operation, when the data stopped being theoretical.

It's worth noting that 2025 coincided with a clear increase in energy awareness on the part of regulators and international institutions as well. Reports on energy efficiency increasingly pointed out that losses in transmission and distribution infrastructure are not a marginal problem, but one of the real areas for optimization.

In practice, this meant one thing. The transformer stopped being a one-time cost. It became an element that generates a constant stream of costs or savings. Depending on how it was chosen. And how it really operates.

This also changed the way designers and investors talk to each other. More questions appeared about long-term scenarios. About load changes. About installation flexibility. About whether the solution chosen today won't become a burden in a few years.

Heading into 2026, it's increasingly difficult to ignore the topic of energy losses. Not because someone requires it. But because the numbers have started to speak for themselves.

And with such data, as we know, you can't win with narrative alone.

What the IEA's "Energy Efficiency 2025" Report Really Says and Why It Matters for Transformers

The International Energy Agency's Energy Efficiency 2025 report clearly shows that energy efficiency has ceased to be an add-on to the energy transition. It has become its foundation. Significantly, the IEA is not talking about futuristic technologies here, but about devices already operating in power grids today.

According to the IEA, the pace of global energy efficiency improvement is still too slow to meet climate goals while maintaining the stability of energy systems. The agency points out that the global rate of efficiency improvement should be around 4 percent annually, while in recent years it has realistically hovered closer to 2 percent. This difference translates directly into greater energy losses, higher operational costs, and increased strain on infrastructure.

The report strongly emphasizes the topic of power infrastructure. The IEA stresses that reducing losses in energy transmission and distribution is one of the quickest and most cost-effective ways to improve the efficiency of entire energy systems. It does not require a technological revolution, but the consistent application of proven, more efficient solutions in equipment like transformers.

Particular attention is paid to no-load losses and load losses in devices operating continuously. The IEA indicates that even small differences in the efficiency of individual infrastructure elements, on a systemic and multi-year scale, translate into very tangible economic effects. This refers to savings counted not in percentages, but in real energy costs and reduced demand for its generation.

The report also notes the changing nature of loads in grids. The growing share of renewable sources, energy storage systems, electric vehicles, and the electrification of heating is causing greater variability in energy flows. In such an environment, devices with lower losses and better partial-load efficiency gain importance, as they operate efficiently not only at nominal points but also under loads far from maximum.

The IEA also emphasizes the cost aspect. Investments in energy efficiency are among the fastest-returning actions in the energy sector. Reducing losses in power equipment decreases the demand for primary energy, lowers operational costs, and reduces pressure to expand generation capacity. This is particularly important under the conditions of unstable energy prices that the market has faced in recent years.

In practical terms, the IEA report sends a very clear signal: the efficiency of infrastructure equipment is no longer an image-related or regulatory choice, but a systemic decision. How transformers are designed and selected directly impacts not only the balance of a single installation but the resilience and costs of entire power grids.

For the industry, this means one thing. In the coming years, it will be increasingly difficult to justify choosing solutions with higher losses based solely on a lower purchase price.

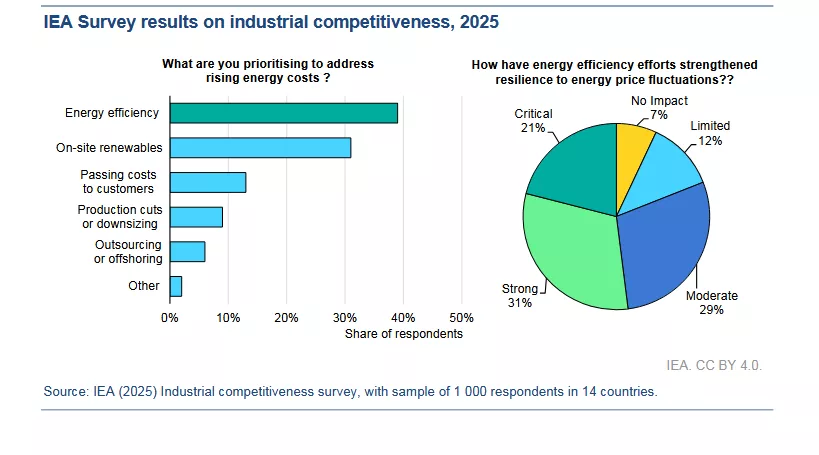

Energy Efficiency as Industry's Key Response to Rising Energy Costs | Source: International Energy Agency, Industrial Competitiveness Survey 2025.

An infographic based on a 2025 International Energy Agency survey shows how industrial enterprises are responding to rising energy costs and price volatility. The survey results from 1,000 respondents across 14 countries clearly indicate that energy efficiency is today the most important strategic priority, surpassing on-site renewable energy investments, passing costs to customers, or reducing production.

The second part confirms that energy efficiency actions genuinely increase companies' resilience to energy price fluctuations. Over 80% of respondents rate their impact as critical, strong, or moderate, with only 7% noticing no effect. This data shows that modernizing power infrastructure, reducing losses, and better energy management directly translate into the stability of operational costs and the continuity of plant operations.

The conclusions from the IEA study clearly indicate that in 2025, energy efficiency ceased to be an environmental add-on and became one of the key tools for building industrial competitiveness and resilience to energy crises.

Dimensions, Logistics, and Installation. Seemingly minor details that caused major pain

If anything consistently derailed schedules in 2025, it wasn't spectacular failures. It was the details. Dimensions. Weight. Site accessibility. The sequence of work. Things that seem obvious at the design stage but in the real world can dominate the entire process.

For a long time, a transformer was treated as an element that would "somehow fit in." In practice, 2025 showed this assumption is becoming less and less valid. Especially when talking about prefabricated transformer substations, modernizations of existing facilities, or projects in densely built-up areas.

The first flashpoint turned out to be dimensions.

Differences of a few centimeters in width or height, which don't raise eyebrows in a catalog, on a construction site could mean having to change the entire foundation concept. In 2025, many projects painfully felt that a substation designed for a "standard transformer" is not always compatible with the actual device available at a given time.

The second problem was weight.

Transporting a transformer stopped being a simple logistical operation.

Load-bearing limits of local roads, access to the construction site, the availability of a crane with specific parameters. All of this started to matter earlier than ever. Projects that didn't consider these aspects during the planning stage often had to make up for it frantically at the end.

In 2025, situations increasingly arose where the transformer was ready, but there was no physical possibility to install it safely according to the original schedule. Additional days of downtime. Additional costs. Additional negotiations. And the question that came too late: did it really have to be this way?

The third aspect is servicing and accessibility after commissioning.

More and more people started thinking not only about how to install the transformer, but how to access it in five or ten years.

In 2025, there were more questions about service space, the possibility of safely removing components, and access to inspection points. This isn't a topic that impresses in a sales presentation. But it's a topic that comes back very consistently in operation.

An interesting phenomenon was that in 2025, more and more logistical problems began to be seen as systemic, not accidental.

International reports on infrastructure project implementation clearly show that underestimating logistics and the integration of technical elements is one of the main causes of delays and cost overruns. In a McKinsey report on productivity in infrastructure construction, it was pointed out that a lack of coordination between design and actual installation capabilities is one of the most frequent sources of time and money losses in energy investments.

In the practice of 2025, this meant a change in approach.

Designers began asking more frequently about things previously taken for granted. Contractors began incorporating logistics into the planning process earlier. Investors began to understand that compactness and predictable installation are not a luxury, but a real saving.

Dimensions stopped being a secondary parameter. They became one of the selection criteria.

Not because someone suddenly started liking smaller devices.

But because in 2025, the market saw very clearly what a mismatch costs.

Heading into 2026, it is increasingly difficult to think of a transformer in isolation from the place where it is supposed to work. Physical reality has returned to design conversations.

And it's likely here to stay.

Documentation, repeatability, and peace of mind during acceptance

If there was one thing that could halt a technically ready investment in 2025, it wasn't a lack of power or equipment failure. It was documentation. Or more precisely, its absence, ambiguity, or a disconnect between what was written and what was actually on site.

For years, documents were treated as a formality to be checked off.

Something that "has to be there" but doesn't necessarily require particular attention. In 2025, this way of thinking stopped working. Distribution System Operators (DSOs), inspectors, and investors began looking at paperwork not as an add-on, but as proof of the entire project's coherence.

The most common problem wasn't the complete absence of documents. They existed. But they were inconsistent. Declarations that didn't fully match the actual execution. Technical data sheets current "at the moment of order" but not necessarily at the moment of acceptance. Operation manuals that resembled a generic product description more than real support for the user.

In 2025, questions that were rarely asked before began to appear more frequently.

Does this transformer actually meet the specific requirements of the grid operator?

Do the parameters stated in the documentation match what was delivered?

Did the manufacturer anticipate operating scenarios that are now the norm, not the exception?

Repeatability proved to be a particularly sensitive point. Serial projects implemented in different locations began to painfully feel the differences between successive deliveries. The same transformer model, but with minor changes in execution. Different component placement. Different documentation. For operation, this isn't a detail. It's a source of unnecessary questions, risk, and stress.

Many contractors admitted openly that in 2025, the greatest relief during acceptance procedures was simply when the documentation matched up. Without excuses. Without "it's similar." Without handwritten additions. Consistency between the design, execution, and paperwork began to be treated as a technical value, not an administrative one.

Operational documents also began to carry increasing weight.

Manuals that actually help the user understand how the transformer works, when to react, and what to watch for. In a world where technical staff are increasingly stretched thin, the clarity and readability of documentation ceased to be a luxury. They became a safety element.

This trend is not accidental.

According to reports from international institutions dealing with technical infrastructure safety, one of the main sources of operational problems is communication errors and a lack of unambiguous technical information. Studies on the reliability of critical infrastructure explicitly state that standardizing documentation and procedures significantly reduces the risk of downtime and unplanned interventions.

In the practice of 2025, this meant a shift in emphasis.

Solutions were increasingly chosen that may not have been the most impressive, but were predictable. Ones that wouldn't cause surprises at the next acceptance. Ones that could be easily compared, serviced, and integrated into existing procedures.

Documentation stopped being an add-on. It became part of the infrastructure. And the peace of mind during acceptance that results from it turned out to be one of the most underrated benefits of a well-chosen transformer.

What to Choose After All This for 2026, and Why Peace of Mind Became the New Currency

After a year like 2025, the temptation to ask directly is natural. If so many things went off track, if theory was verified by practice, if details turned out to be decisive, then what transformer should be chosen for 2026.

And here it's worth slowing down for a moment.

Because the biggest takeaway from the last twelve months is not that the market needs something new. The biggest takeaway is that the market needs something predictable. Solutions that don't cause unpleasant surprises. That fit not only in the documentation but also in the substation, the schedule, and the budget. That comply with regulations not at the edge of tolerance, but with a real safety margin.

In this sense, choosing a transformer for 2026 is less and less a choice of the "technically best" option. Increasingly, it is a choice of the most sensible option in the context of the entire system. Energy losses. Load profile. Logistics. Documentation. Acceptance procedures. Operation in 5, 10, 20... years. This is why the conclusions from 2025 naturally lead to solutions like the MarkoEco and Teo Eco Tier 2 lines in the Energeks offering.

Not because they are the most impressive.

Not because "you have to."

But because they respond precisely to the problems this year exposed.

Meeting Ecodesign Tier 2 requirements without interpretive gray areas.

Low no-load losses where the transformer operates most of the time away from its nominal load.

Predictable dimensions and construction compliant with Distribution System Operator requirements.

Documentation that doesn't require explanations during acceptance.

This isn't a story about a single product. This is a story about an approach. About the fact that after 2025, fewer and fewer people want to improvise. More and more want to know that the decision made today won't come back in two years in the form of a problem.

This entire analysis, from the first section to the last, stems from a very simple assumption: listen and respond to the actual needs of the market.

In the end, we want to say one thing. Thank you.

For the conversations on investment sites.

For the tough questions in projects.

For the exchange of observations and knowledge.

For the feedback that sometimes stings but always teaches.

And for the fact that we increasingly think about the energy sector not only in terms of power, but in terms of responsibility and long-term consequences.

A new year in the energy industry is rarely calm. And that's good.

We wish you for 2026 not an absence of challenges, because they drive progress…

but more predictability where it matters. Less firefighting. More decisions that stand the test of time.

If these topics are close to you, we invite you to our community on LinkedIn.

We share market experiences, implementation insights, and conversations that usually don't fit in product brochures, for people who want to see further than the next acceptance procedure.

2026 is coming fast. It's good to enter it with energy that works for you!

Sources:

Cover Photo: Juan Soler Campello/pexels

International Energy Agency (IEA) - Energy Efficiency 2025

McKinsey Global Institute - Reinventing construction through a productivity revolution

Reviews

No reviews!