Silence. Calm. Safety.

A transformer that doesn’t smell of oil, doesn’t drip onto the floor, and doesn’t demand special maintenance rituals. A dry-type transformer is not an alternative. It’s a decision rooted in logic, in the demands of modern infrastructure, and in the awareness of today’s investors.

Who is this article for?

For designers, integrators, operators, and investors looking for reliable solutions in demanding environments — without compromise.

What will you find below?

Why dry-type transformers win in so many projects

Where oil-based technology can’t deliver

What you gain as an investor

A list of buildings where resin has replaced oil

Estimated reading time: 5 minutes

Reason 1: A dry-type transformer where oil fails

Picture a space where air doesn’t circulate freely, where fans have limited reach, and access to equipment is restricted. A multi-kilometer subway tunnel. A historic church with frescoes on the ceiling. A server room buried in the basement of a class A+ office building. All of these places share one critical challenge: zero tolerance for risk.

Add to that a relative humidity exceeding 80%, dust or suspended particles in the air, plus legal restrictions related to fire protection and a lack of space for oil-based safety systems. In such environments, is an oil-immersed transformer — requiring leak detection systems, retention tanks, and carefully managed ventilation — really the best choice?

Not always.

Oil transformer technology has its niche — primarily in open-air high-voltage substations (GPZ) or wind farms, where space and cooling conditions are favorable. In places where fire protection systems per PN-EN 61936-1 can be implemented, and a potential oil leak poses no threat to people or the environment.

But in many real-world projects — from hospitals and metro lines to heritage buildings and modern residential complexes — priorities shift:

Human and asset safety — especially where vulnerable populations or crowds are present. Even the smallest risk of oil ignition is unacceptable.

High reliability with no servicing — for locations that are difficult or impossible to access, long-term maintenance-free operation is essential.

Limited space and ventilation — where cooling systems can’t be installed or compliance with oil transformer norms is simply not possible.

Aggressive environmental conditions — like steam, salt (in coastal areas), or chemicals (in industrial zones) that can degrade traditional insulation systems.

This is where the dry-type transformer with resin insulation steps in. It doesn’t need oil-based cooling. It eliminates leak risks. It doesn’t require retention tanks. And it performs in environments where other technologies fail. Its sealed, durable design and low maintenance requirements make it the go-to engineering choice wherever traditional oil-filled models can’t keep up.

Reason 2: A dry-type transformer design built for advantage

In the engineering world, it’s not just about efficiency — it’s about reliability and adaptability. A dry-type transformer is like an athlete ready to compete without warming up — compact, focused, and ready to deliver from the start. Its biggest strength lies in a resin-based design that removes many of the typical weak points found in oil-filled units.

What does “dry” really mean?

It’s more than just oil-free.

A dry-type transformer uses no liquid insulation. Instead, it relies on epoxy or polyester resin applied directly to the windings. This not only eliminates the risk of fire — it redefines the way installations are planned. No retention basins, no leak detection systems, no emergency procedures needed.

In practice, this means:

No leaks — even in the event of mechanical damage

No vapor emissions — so no toxic fumes in enclosed spaces

No fire hazard from fluids — lowering fire protection requirements in the facility

A technology that breathes easy

Dry transformer windings are typically made from copper or aluminum wire, then vacuum-impregnated or cast with layers of resin (VPI – Vacuum Pressure Impregnation or CRT – Cast Resin Technology). The result is a build that is:

Moisture-resistant (up to 100% relative humidity)

Mechanically robust — won’t crack or deform

Electrically stable — with insulation strength up to 20–36 kV

Special versions are also available with anti-corrosion protection or electrostatic shielding, ideal for industrial environments with high salt or dust levels.

Silence that matters

Thanks to their compact build and vibration-dampening resin, dry transformers are significantly quieter than their oil-based counterparts. Noise levels typically stay below 50–60 dB, making them suitable for installations near people — in schools, offices, hospitals, or even museums.

This is a design that lets your building breathe — without noise, without oil smells, and without worries about system tightness.

A lightweight performer for demanding tasks

With a compact design and no need for external tanks or auxiliary systems, dry-type transformers weigh 20–30% less than oil transformers of the same rating. That’s a real advantage when installing on upper floors, inside vertical shafts, or in prefabricated energy containers.

Installation times can also be reduced by up to 40%, and fire safety approvals often become unnecessary.

Reason 3: What do you really gain?

For an investor, the key question isn’t “how much does it cost?” but rather “what does it give me?” A dry-type transformer doesn’t just align with modern infrastructure design philosophies — it increases your investment’s value, improves operational conditions, and elevates the technological appeal of the entire facility.

1. You gain greater design flexibility

A dry-type transformer doesn’t require special rooms with oil sumps or expensive leak detection systems. That gives you complete freedom in placement — it can be installed in an office basement, a school, a hospital, or beneath a stadium grandstand. This opens entirely new possibilities in how technical and usable spaces are arranged.

For a developer, that means: more square meters for lease or sale. For a designer: easier integration with existing infrastructure.

2. You gain a time advantage

Time is a resource you can’t get back. A dry-type transformer is a plug & power device — it doesn’t need extended startup processes, specialized leak tests, or long waits for fire protection approval.

In practice, that means you can:

bring your facility online faster,

shorten decision and commissioning chains,

ensure energy continuity during the finishing stages.

The sooner your transformer is installed, the sooner you can launch what comes next — production, leasing, or customer service.

3. You gain safety as a selling point

In hospitals, shopping centers, universities, or metro systems, the absence of oil leak risks and enhanced fire resistance are not just regulatory issues. They’re real advantages in the eyes of users and business partners.

Developers who use dry-type transformers can proudly highlight:

compliance with the highest safety standards,

the building’s eco-friendly profile (no insulating liquids, no soil contamination risk),

safe performance even under heavy load.

This translates to greater customer trust, a stronger reputation, and easier certification in systems like BREEAM or LEED.

4. You gain future-ready technology

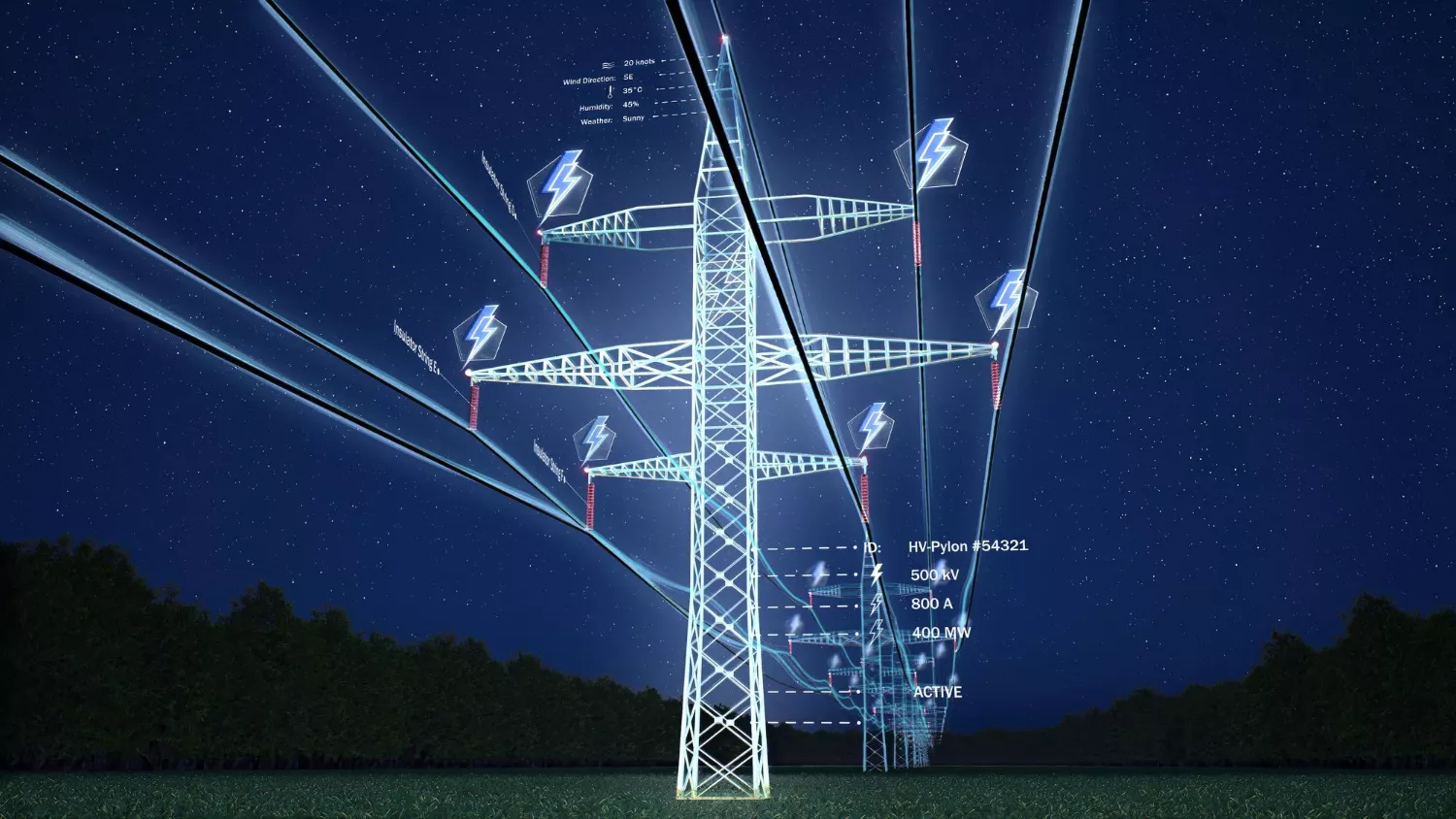

A dry-type transformer is not a cheaper workaround — it’s a leap forward in technology. Especially in versions with online monitoring, humidity and temperature sensors, or digital communication.

As an investor, this lets you:

build infrastructure ready for smart energy management (Smart Grid),

integrate with EMS, BMS, or SCADA,

boost long-term technical value without needing upgrades for years.

This is an investment that doesn’t just meet today’s standards — it anticipates tomorrow’s demands.

5. You gain peace of mind — and that’s priceless

A dry-type transformer runs quietly, reliably, and without needing regular inspections. It doesn’t leak. It doesn’t buzz. It doesn’t require a technician on call.

Thanks to that, you:

reduce the number of unexpected service calls,

improve system availability for users (zero downtime),

focus your time and resources where they matter most — on growing your business, not maintaining equipment.

Operational calm and technical stability — these are the foundations of long-term infrastructure peace of mind.

Reason 4: Where do we install dry-type transformers? Not just underground

Though many designers associate dry-type transformers with installations buried below ground — metro tunnels, stations, underground parking garages — their use goes far beyond technical infrastructure. With their versatile construction, environmental resistance, and refined operation, they’re now found wherever uncompromising reliability and human safety are required.

Public transport – the silent heart of the city

In metro lines, trams, and urban transport hubs, where every square meter matters and delays can paralyze the system, dry-type transformers are the perfect match. They operate close to traction systems, in low-ventilation areas, underground, often in humid and dusty environments.

No oil sumps. No fire risk. Minimal servicing. That’s why urban rail systems around the world are moving away from oil-based solutions in favor of resin-insulated units.

Hospitals – where reliability equals life

In healthcare facilities, downtime means more than financial loss — it can threaten lives. That’s why dry-type transformers are now standard in modern hospitals and clinics. They operate silently, require minimal maintenance, and pose no ignition risk. Most importantly, they can work in direct proximity to people and sensitive medical devices.

They’re an invisible but vital part of hospital infrastructure, keeping equipment stable and letting medical teams focus on patient care.

Shopping malls and A+ office buildings – comfort that sells

In high-end commercial spaces, every aspect of user experience matters: acoustic comfort, safety, clean air, and reliable power. Dry-type transformers meet all these needs. They can be installed in basements, technical floors, or even inside utility walls — quietly, safely, and without the need for fire zones.

For building owners, this means greater rental flexibility, less structural disruption, and better chances of earning green building certifications.

Heritage and sacred buildings – when fire would be a cultural tragedy

In museums, churches, archives, and other heritage sites, every second counts when it comes to fire prevention. Dry-type transformers minimize fire risks at the source — they contain no liquids, so they can’t spill or ignite.

Their compactness and quiet performance also mean they can be discreetly installed without interfering with the structure. This is technology that protects the past while seamlessly coexisting with the present.

Industrial sites – where conditions don’t forgive mistakes

In chemical plants, processing facilities, steelworks, or manufacturing halls, transformer conditions can be extreme: moisture, heat, dust, corrosive substances. An industrial-grade dry-type transformer — with shielding, anti-corrosion coatings, and extra protections — operates where others would fail.

It’s an investment that keeps production moving and ensures continuous power even in the harshest environments.

A dry-type transformer is neither a trend nor a compromise. It’s a conscious decision made by forward-thinking investors who know that not every space should smell like oil — and not every project should be constrained by outdated limitations.

Need a transformer for a unique site? You’re in the right place — we’ll match you with the right technology that works from the very first start-up.

Reason 5: A pillar of modern installations

It doesn’t make noise, doesn’t seek attention, and doesn’t show up in the maintenance log every week. A dry-type transformer works silently in the background, but it’s its reliability that determines whether a facility runs without interruptions. In a world where every second of uptime matters, this type of transformer is like a seasoned athlete — strong, resilient, and invisible to the end user.

Stability you can build on

Silent doesn’t mean passive. A dry-type transformer is an active part of the infrastructure, operating non-stop for years without the need to refill cooling media, without the risk of leaks, and without making noise. Its design, based on resin insulation with high dielectric and thermal strength, allows it to run for decades without intervention — even in challenging environments.

That means:

no downtime from cooling system failures

no need to replace or regenerate oil

minimal maintenance limited to visual checks and insulation resistance testing

As an investor, you’re not just buying a device — you’re buying peace of mind for years, knowing that even if you forget about the transformer, it will still do its job.

Ready to go – right away

Unlike oil-based systems, which often require long prep work after installation — including leak testing, oil filling, and safety system verification — a dry-type transformer is ready to operate immediately after connection. It’s the perfect solution for fast-track projects where timelines are measured in days, not weeks.

Thanks to its compact and sealed design, it can be transported and installed without risk of internal damage — eliminating last-minute surprises during commissioning.

An acoustic edge – more comfort, less noise

In today’s installations, where the transformer is often located close to people — in offices, schools, hospitals, or universities — every decibel counts. Dry-type transformers are known for their exceptionally low noise levels, often below 50 dB(A), making them leaders in their category for acoustic comfort.

This translates to:

better work and learning environments, free from hums and vibrations

more design flexibility — no need for special soundproof enclosures

a better user experience, which positively affects building perception

It runs nonstop, because it’s built not to fail

Investors who choose dry-type transformers often point to one standout experience: the silence that brings reassurance. It’s not just the lack of noise — it’s the absence of stress from servicing, permissions, inspections, and unplanned shutdowns.

This is a unit that simply runs — whether you’re powering a shopping mall, hospital, or metro line. It doesn’t demand attention. It doesn’t trigger alerts. It delivers energy — and stays out of sight.

Curious why the dry-type transformer is gaining ground in safety and environmental resilience? Check out this article too:

👉 Dry-type transformer for indoor applications: Safety and flexibility

Dry-type transformer. The future already in operation

At Energeks, we believe the best decisions are those that anticipate problems before they arise. That’s why we deliver solutions that not only meet today’s challenges, but lay the groundwork for the future of energy systems — calm, safe, and resilient to change.

If you’re designing infrastructure that must perform reliably regardless of location, environmental conditions, or service availability, the dry-type transformer is your ally. From hospitals and malls to metro systems and historic monasteries — its job isn’t to blink with LEDs, but to quietly ensure continuity and stability, day after day, for decades. See what we can offer.

Every one of our projects is a blend of engineering expertise, real-world implementation experience, and listening to what users actually need — from engineers to facility operators.

Want to talk about applying dry-type transformers in your project? Or maybe exchange insights on urban or industrial power distribution?

Join our community on LinkedIn — where we share knowledge, implementation stories, and practical tips to help you build systems that stand up to time, weather, and emergencies.

At Energeks, we don’t just design equipment. We create a future people want to help build. And we’re here to help you make it real — no matter what stage your project is in.

Sources:

Reviews

No reviews!