Power Systems

Winter rarely arrives with a bang.

It more often creeps in quietly.

First, a few chilly mornings.

Then dampness that doesn't disappear even at noon.

And finally, small, easy-to-ignore signals. The transformer is operating. Parameters are still within spec. Nothing is whining. Nothing is sparking. And that's precisely when the problem begins.

Water vapor condensation inside a transformer tank doesn't produce spectacular symptoms.

It doesn't shut down the grid in one day. It doesn't send an SMS alarm. It works like a slow corrosion of trust. Accumulating on the tank walls, in the paper insulation, and in the oil, it systematically reduces the electrical withstand strength of the system.

This is a topic that returns every winter. And almost always when it's already too late.

For years, we have worked with medium-voltage transformers in real operating conditions.

We have seen transformers that were correctly sized electrically, met EcoDesign Tier 2 requirements, had complete documentation, and new oil.

And yet, after two or three winter seasons, they started causing problems.

The common denominator was very often moisture.

Water vapor condensation is not a manufacturing defect. It's a physical phenomenon.

This text is for everyone who wants to understand what really happens inside a transformer tank in winter and how to prevent it before the quiet killer starts counting the losses.

After reading, you will know where the water in a transformer comes from, why the problem intensifies in winter, what the real consequences are for the insulation, and how to mitigate the risk through both design and operation.

Reading time: 12 minutes

Where does water vapor in a transformer tank come from

Air always contains water.

Even when it seems dry.

Relative humidity is not an abstract parameter from a weather forecast. It is the actual amount of water vapor that can condense when the temperature drops.

A transformer tank is a closed space, but it is rarely perfectly sealed in the physical sense. Even hermetic constructions have micro-phenomena of diffusion.

Add to this moments of opening, transportation, installation, oil filling, and maintenance work.

If air with a specific humidity enters the tank interior, and then the temperature of the tank walls drops, water vapor begins to condense.

The dew point is often reached faster than we expect.

In winter, this mechanism works mercilessly.

During the day, the transformer operates, the oil heats up, and the air inside increases its capacity to carry moisture.

At night, everything cools down.

The water vapor seeks the coldest surface.

Most often, these are the upper parts of the tank and structural components

Why winter acts as a catalyst for the problem

Winter is a season of large temperature amplitudes. A difference of several dozen degrees between day and night is not unusual. For a transformer, this means the cyclic breathing of the oil and air volume.

The key concept here is the dew point. This is the temperature at which air with a given relative humidity can no longer keep water vapor in a gaseous state.

For example, air with a relative humidity of 60% at a temperature of 20°C reaches its dew point at around 12 degrees.

This means that any surface colder than this threshold becomes a site for condensation.

The walls of a transformer tank in winter very often have a temperature significantly lower than the air inside. Especially the upper parts of the tank, the covers, and structural components protruding above the oil level. That is where water vapor condenses first.

In breathing transformers, every cooling cycle means drawing in air from the outside. If the air dryer is worn out, incorrectly sized, or simply forgotten, moisture enters the interior. At temperatures near zero, the air's capacity to store water vapor drops sharply, so condensation occurs almost immediately.

In hermetically sealed transformers, the phenomenon is subtler but still exists. Oil changes volume with temperature.

With a temperature drop of 20°C, the oil volume can decrease by about 1%.

In a tank with a capacity of several thousand liters, this means real changes in pressure and the performance of seals.

Moisture doesn't enter through the door, but it enters through the window of physics. The diffusion of water vapor through sealing materials is slow but non-zero. Winter gives it time and favorable conditions.

Additionally, in winter, the transformer often operates under a higher load. Heat pumps, electric heating, electric vehicle charging infrastructure. More heat during the day, more cold at night.

Ideal conditions for condensation.

What happens to water after it condenses

Water inside a transformer tank does not behave like a puddle on concrete. Its fate depends on many factors.

Some of the condensed water flows down the tank walls and enters the oil.

Transformer oil has a limited capacity to dissolve water.

At a temperature of around 20°C, this is in the range of several dozen ppm*.

*ppm = parts per million - equivalent to 1 milligram per liter of substance (mg/l) or 1 milligram per kilogram (mg/kg) of water.

Excess water migrates into the paper insulation. And electrical insulation paper acts like a sponge. Once absorbed, moisture is very difficult to remove from it.

Each percentage point increase in water content within the paper dramatically lowers its electrical withstand strength and accelerates aging. This is not a linear process. It's a curve that suddenly begins to spike.

Olej i wilgoć. Toksyczny duet

Olej transformatorowy pełni dwie kluczowe funkcje. Izoluje i chłodzi. Wilgoć uderza w obie naraz.

Rozpuszczalność wody w oleju transformatorowym silnie zależy od temperatury.

W temperaturze 20° C typowy olej mineralny jest w stanie rozpuścić około 30 do 50 ppm*

Przy 60° C ta wartość może wzrosnąć nawet trzykrotnie.

To oznacza, że w ciągu dnia olej wchłania wilgoć, a w nocy, gdy temperatura spada, nadmiar wody zaczyna się wytrącać.

Już niewielki wzrost zawartości wody w oleju powoduje spadek napięcia przebicia.

Przy poziomie 20 ppm napięcie przebicia może wynosić ponad 60 kV.

Przy 40 ppm spada często poniżej 40 kV.

To różnica, która w warunkach zwarciowych decyduje o przeżyciu lub porażce izolacji.

Zimą zdradliwy jest efekt pozornej poprawy.

Pobierając próbkę oleju w niskiej temperaturze, można uzyskać wynik wskazujący niższą zawartość wody rozpuszczonej. Część wilgoci znajduje się wtedy już w papierze lub w postaci mikrokropelek, których standardowe badania nie zawsze wychwytują.

Do tego dochodzi przyspieszone starzenie oleju.

W obecności wody i podwyższonej temperatury rośnie tempo reakcji chemicznych.

Tworzą się kwasy. Zwiększa się liczba kwasowa.

Olej traci swoje właściwości szybciej, niż przewiduje IEEE.

Oil testing in winter - 3 key methods

In winter, interpreting oil test results requires particular caution.

Three tools become crucial.

The first is determining water content using the Karl Fischer method.

The result must always be referenced to the oil temperature at the time of sampling and the transformer's operational history. A low ppm result from a cold sample does not mean moisture is absent. It may mean it has already left the oil.

The second tool is the analysis of Dissolved Gases (DGA).

Elevated concentrations of hydrogen and carbon monoxide in the absence of classic fault gases can be the first signal of insulation paper degradation caused by moisture.

The third element is observing trends, not single data points.

In winter, comparing results from different seasons is especially important.

Spikes in water content between summer and winter tell more than the absolute value.

Analysis of transformer oil allows for detecting the effects of water vapor condensation before it leads to degradation. This type of analysis helps identify insulation threats before winter failures occur. Photo CC: Freepik/13628

A transformer doesn't fail on the day it's tested. It tells a story that one must know how to read.

Paper insulation. The weakest link

At first glance, paper insulation seems like a secondary element.

It's not visible from the outside, it doesn't have parameters easily sold in a table, it doesn't impress like power or efficiency. And yet, it is very often what determines the real end of a transformer's life.

Electrical insulation paper ages by definition.

The process of cellulose depolymerization always occurs, even under ideal conditions.

The problem begins when moisture enters the game. Even a small increase in the water content of the paper acts as an aging catalyst. It is accepted that each doubling of the paper's moisture content significantly accelerates the degradation of cellulose chains.

What does this mean in engineering practice?

A drop in the mechanical strength of the windings. The paper ceases to serve as a stable spacer, and the windings lose their resistance to the electromechanical forces that appear during faults.

A transformer can operate correctly for years, until the first major grid test. Then, weak insulation doesn't fail spectacularly. It simply doesn't hold up.

Moisture is not a failure. It's a process.

A quiet killer that doesn't destroy immediately but systematically erodes the transformer's safety margin. And that's precisely why paper insulation is often the weakest link in the entire system.

Not because it is bad, but because it is merciless towards neglect.

Hermetic transformer or one with a conservator? Differences in moisture risk

In winter, a transformer quickly reveals which school of construction it comes from.

A hermetic transformer, by definition, limits contact with external air. The oil, gas space, and tank form a closed system. For moisture, this is a difficult situation. There are no revolving doors, no daily invitations for water vapor to enter. This is a huge advantage during the heating season.

But a hermetic transformer is not a magical vacuum capsule.

It's still steel, seals, and people doing the assembly. One poorly tightened connection, one gasket installed on a humid day, and moisture has a subscription for years. No dryer, no vent, no evacuation route. Silence, calm, and very long-term consequences.

Constructions with an oil conservator work differently.

Here, the oil volume is compensated by contact with atmospheric air.

This is a known, proven, and still common solution. However, in winter, it requires character.

An air dryer is not a decoration. It's the security guard at the gate. If it's asleep, moisture walks in without asking. And in winter, a dryer tires out faster than in summer. The gel loses effectiveness, indicator colors can lie, and every night's cooling cycle is another dose of moisture sucked inside.

In short, it looks like this. In a hermetic transformer, the design and installation are responsible. In a transformer with a conservator, operation is responsible. Physics is impartial, but very meticulous.

Therefore, the choice shouldn't start with the question which is better, but rather who will take care of it during winter.

We've already covered this topic in more detail here:

Transformer oil conservator – what it is, how it works, and when it is needed

Because water vapor doesn't have a favorite technology.

It simply checks where it can enter without knocking.

Common installation mistakes

Moisture is rarely the fault of the equipment itself.

More often, it's the result of small oversights:

✖ Opening the tank in humid conditions without protective measures.

✖ Leaving the transformer without oil for extended periods.

✖ Transport and open-air storage without protective covers.

✖ Lack of preheating before startup in winter.

Each of these elements seems harmless on its own. Together, they build the perfect environment for condensation.

Symptoms that are easy to ignore

The first signals of moisture presence are subtle:

✖ Slight changes in oil parameters.

✖ A gentle increase in the dissipation factor (tan delta).

✖ A minimal reduction in breakdown voltage.

They often end up in a periodic test report and remain there for years. Without any action (✖!) because, after all, the transformer is operating. The problem is that physics doesn't read reports.

How to reduce the risk of condensation

It's impossible to completely eliminate moisture.

But it is possible to manage it.

From a design perspective, it's worth opting for hermetic constructions.

Ensure appropriate oil volume reserves and solutions that minimize temperature fluctuations.

From an operational perspective, discipline is key.

Inspections, oil testing, responding to deviations.

In winter, the startup procedure becomes particularly important.

Gradual loading.

Avoiding sudden heating and cooling cycles.

A modern approach to MV transformers

Modern transformers are designed with such scenarios in mind.

Winter will always come.

Water vapor condensation doesn't make noise.

It doesn't flash red.

But it leaves a mark every season.

Conscious design, correct installation, and attentive operation allow you to erase that mark before it turns into a costly failure.

That's why the choice of a transformer is increasingly not just a decision about power and voltage.

It's becoming a decision about resistance to real operating conditions.

If you are considering purchasing or replacing a transformer, our current range of oil-immersed transformers has been designed precisely for scenarios where moisture, temperature variability, and seasonal load changes are the norm, not the exception.

They are complemented by dry-type transformers for where environmental conditions or the nature of the installation require a different approach.

We also invite you to the Energeks community on LinkedIn, where we regularly share knowledge from the power engineering industry.

SOURCES:

IEEE Power and Energy Society. Moisture effects in oil filled transformers.

CIGRE Technical Brochures on transformer insulation ageing.

IEC publications on insulating liquids and moisture management.

Cover Photo: Freepik/2148635097

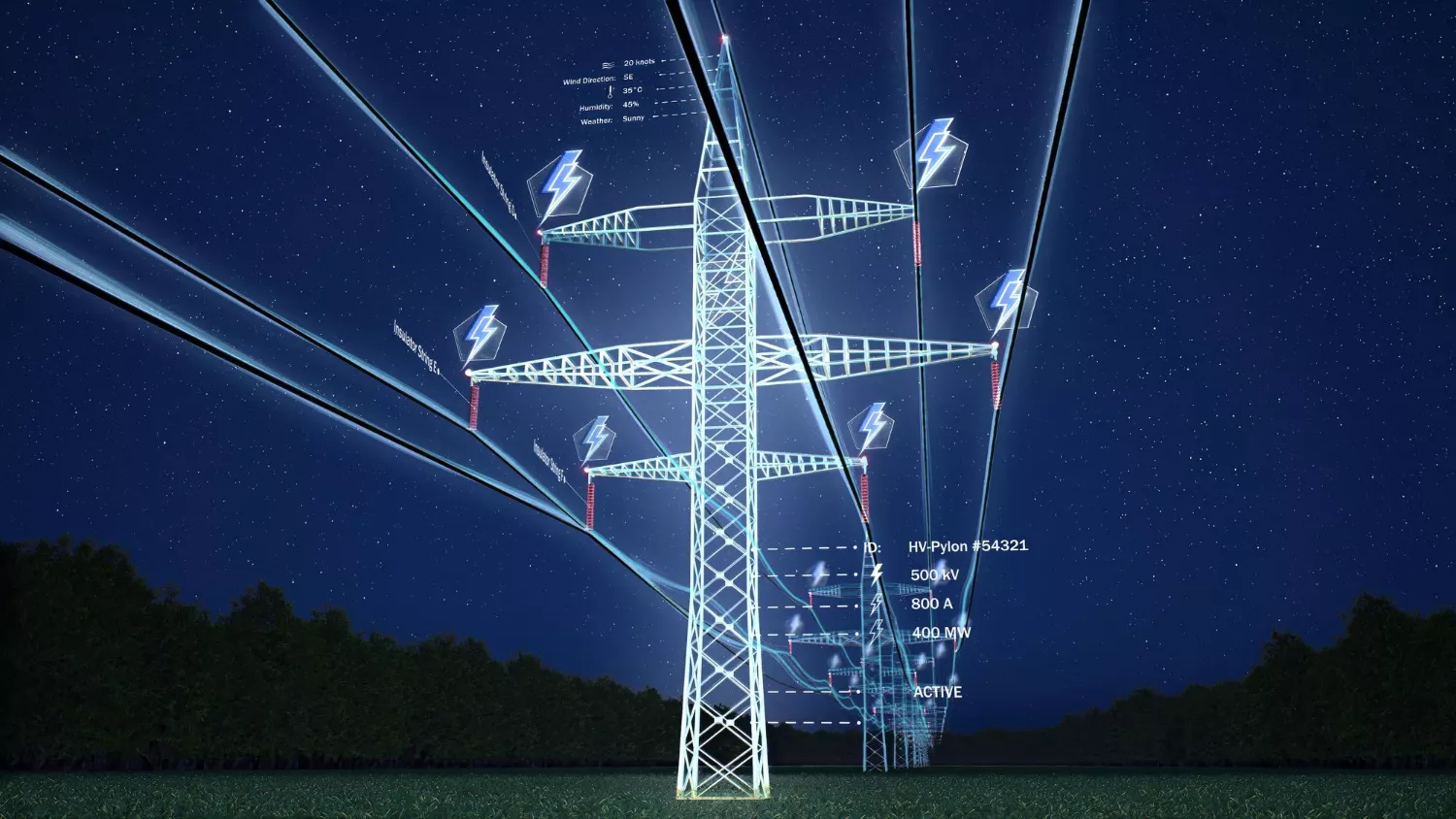

When voltage rises faster than expected

In the world of modern energy systems, the line between standard operation and serious risk is often razor-thin. Transient overvoltages, spikes caused by lightning strikes, overloads, or grid disturbances can occur within milliseconds and bring weeks of work to a halt.

At the same time, dynamic industrial installations, photovoltaic farms, and compact substations today demand much more than just voltage conversion. A transformer is no longer a passive link. It becomes an active participant in the power system.

It protects, it monitors, it communicates, and it adapts.

This article presents four specialized solutions applied in medium-voltage transformers. Each addresses a specific need: safety, control intelligence, resilience to environmental conditions, or ecological impact. While not every application requires all features, understanding them allows for better decision-making.

If you manage energy infrastructure, work in the industrial sector, operate PV farms, or are responsible for ensuring the uptime of distribution substations, this overview may help you avoid costly mistakes and optimize your equipment choices.

What you’ll find in this article:

How a transformer with surge protection works and when to use it

What sets a transformer with built-in automation apart and what it offers

Why TOGA terminals and MIDEL oil are a strong combination for modern installations

The benefits of a transformer in a metal enclosure with fire-resistant oil

Reading time: approx. 11 minutes

What does it mean when a transformer does more?

A standard transformer is just the beginning. Today’s energy systems demand solutions tailored to the environment: stormy weather, dynamic loads, the need for remote supervision, or limited installation space.

A modern transformer can now perform more functions than ever before. It can:

monitor and transmit data on load, temperature, and insulation condition

respond to voltage fluctuations or overloads

protect against disturbances, both from the grid and from consumers

minimize fire risk by using fire-safe oils and sealed enclosures

Let’s now take a closer look at the specifics.

Transformer with surge protection – when to use it and how it protects installations from lightning and grid spikes

Voltage spikes are among the most common and dangerous causes of failure in energy infrastructure. A surge protection device (SPD) has a single purpose: to immediately reduce excessive voltage to a level safe for the transformer's insulation and the rest of the system.

Integrating a surge arrester directly into the transformer enclosure is a solution increasingly seen across Europe’s medium-voltage installations, from industrial zones to rural distribution substations.

This approach minimizes reaction time, lowers installation costs, and reduces the number of components exposed to corrosion or mechanical failure.

The SPD works by redirecting the surge energy to ground.

It reacts within microseconds to sudden voltage increases, typically from lightning or switching large loads. Modern class B and C devices can withstand surges of several tens of kA while maintaining performance across repeated events.

Integrating an SPD into the transformer can be crucial where reliability and restoration time are paramount. In many European countries, this is now standard in high-risk facilities: hospitals, data centers, EV charging stations, and PV installations in open areas.

What does a surge protection device do?

It is a component that instantly diverts surge energy (such as from a lightning strike) to ground before it can damage the transformer's insulation.

In practice, it:

protects transformer windings and downstream components

extends the life of the entire MV system

prevents production downtime and losses

Key data:

response time: <25 ns

sparkover voltage: 15–45 kV (depending on grid design)

service life: >10 years under standard surge exposure

When to use:

substations installed in open terrain

areas with frequent lightning (e.g. mountainous or coastal zones)

grids with unstable voltage supply

mobile or temporary substations

Transformer with control automation – intelligent solutions for MV grids and modern industrial installations

The development of smart grids, industry automation, and the need for remote infrastructure management has led to transformers increasingly being equipped with built-in automation systems. These units do more than measure voltage and current – they also communicate with SCADA systems, enable dynamic reconfiguration, and detect faults in real time.

Transformers with built-in control systems are most commonly used in locations with high load variability – industrial plants, urban networks, EV charging hubs, and interconnection points for distributed energy resources.

The automation package can include energy quality meters, winding and oil temperature sensors, tap changer controllers (OLTC), and communication modules supporting protocols such as IEC 61850, Modbus TCP/IP, or DNP3.

This allows operators to adapt transformer operation to network conditions in real time, anticipate overloads, and optimize energy flow.

Additionally, built-in automation helps meet European efficiency and environmental regulations such as the Ecodesign directive and Regulation 2019/1783. Thanks to precise monitoring, transformers can operate with reduced losses and maintain performance for longer periods.

What does automation include?

integrated PLC controller

electrical parameter recorders

oil and winding temperature sensors

communication interface (Modbus, CAN, IEC 61850)

Typical functions:

oil and winding temperature control

remote switching

load analysis

predictive maintenance

Application example:

A 2 MW PV farm in western Europe reduced average winding temperature by 6°C using a transformer with automation. This extended service life by 4 years and eliminated the need for unplanned maintenance.

Where does it work best?

heavy industry (e.g. steelworks, foundries)

solar and wind farms

urban smart grids

temporary container substations

Transformer with TOGA terminals and MIDEL oil for photovoltaic installations

TOGA terminals (TO – touch-proof terminals) are a special connector format that enhances safety when connecting power cables. These terminals provide superior insulation, reduce the risk of accidental short-circuits, and simplify maintenance.

They are often selected where access to the transformer is limited or where operations are carried out in the field – such as PV farms, open-air industrial applications, or containerized solutions.

Even more important is the choice of insulating fluid.

Traditional mineral oil, while reliable, is increasingly being replaced by safer and more advanced alternatives. One of them is MIDEL – a synthetic ester with a very high flash point (over 300°C) and extremely low toxicity. It is biodegradable, fire-safe, and compliant with environmental regulations in many European countries.

Using MIDEL oil in transformers with TOGA terminals combines safety and sustainability. Such units are more resilient to environmental conditions, require less maintenance, and can be installed in protected areas – near water sources or in nature reserves.

A TO + MIDEL transformer is the ideal choice for those who refuse to compromise on operational safety or environmental impact.

TOGA terminals:

fast and safe plug-in cable connection

minimized short-circuit risk during installation and maintenance

better ergonomics in field and industrial setups

easier inspection and servicing

MIDEL oil:

fire-resistant – flash point above 300°C, far higher than mineral oil

biodegradable – over 98% breakdown within 28 days

non-toxic – safe for people and ecosystems even in case of leaks

compliant with EU norms – REACH, RoHS, approved for use near water protection zones and Natura 2000 areas

Applications:

ideal for PV farms where fast installation, safety, and environmental resilience are essential

effective in industrial contexts where installation space is limited and safety is a priority

Technical and environmental benefits:

reduced fire and contamination risk

high reliability under variable weather conditions

eco-conscious choice aligned with ESG and sustainability policies

Transformer in a metal enclosure with MIDEL oil – sealed, durable, and safe in a compact format

A compact design, easy transport, enhanced mechanical resistance, and full safety compliance – these are the main advantages of transformers housed in a metal enclosure and filled with MIDEL oil. These units are increasingly chosen for prefabricated transformer stations, urban installations, and critical infrastructure.

The metal enclosure offers protection against mechanical damage, moisture ingress, and environmental exposure. Combined with a well-selected cooling system – either natural or forced – it enables long-term, stable operation without frequent maintenance.

Using fire-resistant synthetic MIDEL oil increases installation safety, reducing the risk of fire in case of internal faults or overheating. The oil does not release toxic fumes and can be used safely even in highly regulated environments such as medical facilities or public infrastructure nodes.

The M + MIDEL transformer in a metal enclosure is a particularly attractive solution for investors planning grid expansion in confined or complex environments. Ready to connect and resistant to external influences, these transformers deliver uncompromised reliability.

Metal enclosure:

increased mechanical durability and sealed construction

protection against moisture, dust, and mechanical impacts

ideal for prefabricated substations and urban infrastructure

enables fast installation and simplified logistics

Applications:

container and prefabricated substations where quick setup and sealed housing matter

critical infrastructure – hospitals, public facilities, urban areas

environmentally sensitive locations – without risk of soil or water contamination

Technical and operational advantages:

low noise and vibration emissions

reduced failure rates and extended maintenance intervals

suitable for challenging environmental conditions

compliant with PN-EN 60076 and Ecodesign directive

When a transformer becomes more than a box

A transformer is no longer just an auxiliary device.

In the era of distributed networks, electromobility, decentralization, and rising environmental requirements, it becomes a strategic part of infrastructure. Choosing the right configuration – with surge protection, automation, safe terminals, or eco-friendly oil – directly impacts system reliability, safety, and operating costs.

Each of the solutions described has a valid purpose and application. The best decisions are those that consider not just today’s needs but also where your installation is heading in the years ahead.

We hope this article helped you see transformers from a new perspective.

If you are planning a project where long-term safety, clear documentation, and adaptability are essential, we are here to support you.

We help select, configure, and test transformers to meet PN-EN 60076 compliance, ready for commissioning, and built for decades of operation.

Check out our transformer range – available in versions compliant with PN-EN 60076, with full routine testing and optional special tests when required by your project or environment.

Planning a retrofit or new station? Get in touch – our engineers can help tailor solutions to your specific conditions.

Join our community on LinkedIn – we share hands-on knowledge from hundreds of real-world projects.

Thank you for reading to the end.

We hope this article offered not just information but inspiration for asking better questions – because better questions are what move the energy sector forward.

Sources:

Power Transformers - Ecodesign requirements apply to this product.

One decision that can eat away your solar ROI

It was supposed to be a quick return on investment.

A small 99 kW PV farm, set up by a farmer in a rural part of Europe, was expected to pay for itself within five years.

Everything checked out: the location, the panels, the inverters, the grid connection terms. Everything except one detail.

The transformer. A cheap, “universal” model that, on paper, could handle any system.

In reality? Excessive no-load losses, incompatibility with the medium-voltage grid, unstable voltage during peak hours, and months of frustrating back-and-forth with the distribution operator. Now, 18 months later, energy output still fails to meet expectations.

This blog is a remedy for mistakes like that. Written by engineers, for engineers — and for anyone building a PV farm with the help of a friend on the weekend.

If you're wondering which transformer to choose for a 50 kW, 100 kW or maybe 150 kW PV farm — you're in the right place.

You will learn which parameters actually matter, how to avoid mistakes that can cost thousands, and what questions to ask your substation designer before it's too late.

In this article, you’ll learn:

When 50 kW is still a micro-installation and when it becomes a professional PV plant

What parameters matter when selecting a transformer for 50, 100 or 150 kW PV systems

Why a standard transformer might not work well with solar

Whether it's possible to build a PV system without a transformer — and when

How to select a PV transformer step by step, using real examples

What mistakes investors and installers often make when choosing a transformer

Dry vs. oil transformers — what pays off in agricultural vs. industrial settings

How to stay compliant with your grid operator and deliver quality energy

Reading time: 12 minutes

What transformer for a 50, 100 or 150 kW PV farm?

It might not look like much — a PV installation rated at 50, 100 or 150 kW. It’s not a utility-scale solar plant, but it’s not residential either. Often it’s a private, agricultural or small business project with one goal in mind: not just to save money, but to earn it.

And this is exactly the power range where things often go wrong — in ways that are hard to reverse. The common denominator? One simple but high-stakes question: what transformer is actually right for a small PV farm like this?

On industry forums, in project documentation, in investor meetings, we keep hearing the same doubts:

Is a 100 kVA transformer enough for a 100 kW PV plant?

Should I oversize to 200 kVA “just in case”?

Can I just use a stock transformer from the warehouse?

And that’s where the trouble starts. Because when it comes to PV systems in the 50 to 150 kW range, a transformer cannot be an afterthought. It’s not just about power. It’s about compatibility with the MV grid, resilience to voltage fluctuations, and understanding that at 50 kW, you are already playing in the professional league — not at home.

Is 50 kW still just a “system,” or is it already a PV farm?

From an investor’s perspective, 50 kW might still feel “small” — a few panel strings on a warehouse roof or a field near the main building. But in the eyes of energy law and the distribution network operator (DNO), 50 kW marks a turning point.

In practice:

It is the upper limit of a micro-installation

Anything beyond falls under the category of “small-scale renewable installation” (MIOZE)

Which means:

No more simplified connection procedures

A full design and approval process is now required

Strict technical criteria apply, including harmonic distortion (THDi), voltage compliance, and galvanic separation

That’s why a transformer for a PV system in this category is not just a voltage adapter. It’s a fully integrated component of the electrical infrastructure. It must be compliant with MV grid specifications, resilient to variable load conditions, and designed with future upgrades or energy export in mind.Common mistakes? Unfortunately, all too familiar

Investors often limit the declared capacity to 49.9 kW to avoid the regulatory burden of MIOZE procedures. Yet they still order a 100 kVA transformer “just in case.” Or they install inverters that, at peak generation, push up to 110 percent of nominal power. The result?

Higher no-load losses – the transformer operates outside its optimal efficiency range

Increased harmonic distortion (THDi) – standard transformer cores are not designed to handle PV inverters

Voltage spikes on the MV side – without voltage regulation at ±2.5 percent, synchronization and compliance issues start to appear

What was supposed to be “extra headroom” becomes a bottleneck. Good intentions turn into unexpected faults, performance drops, and delayed settlement with the grid operator.

What parameters define a good transformer for a 50 to 150 kW PV system?

It depends on the configuration, but the core rules are consistent:

MV grid voltage – most commonly 15.75 or 20 kV, depending on region and local utility

Transformer ratio – typically 0.4/15.75 kV, though 0.8/15.75 kV is required for 800 V inverter outputs

Grounding – defined by the operator’s requirements: isolated neutral point, resistor grounded, or directly grounded

Usage profile – rooftop PV for five-day operations or ground-mounted for seven-day continuous exposure

A 63 kVA transformer is usually sufficient for a 50 kW installation. But if you plan to scale up, it is better to consider 80 to 100 kVA. The condition: proper insulation rating (at least class F), cooling method (ONAN or AN), and a matching voltage ratio for the inverters.

Conclusion

If you're asking yourself which transformer to choose for a 50, 100 or 150 kW PV system, remember there’s no room for guesswork. It’s like choosing the foundation for a building. It might not draw attention at first, but everything else will depend on it. And the cost of getting it wrong stays with you long after the invoice is paid.

What kind of transformer does a PV system really need?

At first glance, a transformer seems like a simple component. Two windings, voltage conversion, an iron core. What could possibly go wrong?

Plenty. That assumption is one of the most common reasons why PV systems underperform. Using a standard transformer for an application it was never meant for creates a mismatch that’s invisible until energy losses, overheating or grid compliance issues show up.

Because solar is not like industrial power supply. There is no steady consumption around the clock. Instead, there are rapid surges at noon, near-zero flow at night, and high levels of harmonic distortion caused by inverters. As a result, the operational environment for PV transformers is fundamentally different.

A PV transformer plays a different tune

So what sets a PV transformer apart from a conventional one?

Load profile

In solar, the transformer faces highly asymmetrical conditions. No generation at night, peak output midday. Standard units are not built for such swings.Power direction

In a PV system, power flows from the inverters into the grid – the opposite of traditional setups. This affects thermal behavior and winding design.Harmonics

PV inverters produce current distortion, typically 6 to 10 percent THDi, sometimes more. A transformer for PV must have a suitable core, larger winding cross-sections, and often oversizing to prevent overheating under harmonic load.No-load conditions

On cloudy days or low-irradiance periods, inverters may generate little to no power, but the transformer remains energized. In such cases, no-load losses become a real cost driver.

All this means that a standard transformer might "work" in theory, but in practice leads to reduced efficiency, higher bills, and frustrated technicians.

What are the minimum specs for a PV transformer?

Insulation class: at least F (155°C), ideally H (180°C), for thermal safety under overload

Cooling type: ONAN (natural oil and air cooling), ideal for outdoor transformers up to 250 kVA

Low-voltage winding: matched to the inverter output (0.4 kV or 0.8 kV) – the wrong ratio can trigger failures

Harmonic tolerance: windings and core must handle THDi levels up to 10 percent without excess losses

Example from the field:

A 150 kW PV farm using 800 V inverters was fitted with a 0.4/15.75 kV transformer. After just three months, problems emerged: overheating, inverter shutdowns, lost output. Diagnosis? A mismatch in voltage ratio. The transformer was replaced with a 0.8/15.75 kV unit with an amorphous core. Production rose by 11 percent, and the system finally delivered as promised.

Can a standard transformer be used in a PV system?

This question comes up surprisingly often. Can I use a regular transformer for a solar farm?

Technically, yes — if efficiency, durability and grid compliance are not your priority.

But if you expect your system to perform reliably for 15 to 20 years, the answer is simple: it’s not worth the risk.

Can you build a PV system without a transformer? When it works and when it’s asking for trouble

This is one of the most commonly searched questions among individual investors and small business owners. Does a PV installation really need a transformer? Especially in the 30 to 50 kW range, where the line between a micro-installation and a small PV plant is blurry and every additional component, including the transformer, adds to the cost. So the question arises — could you skip it?

PV without a transformer — wishful thinking or real option?

Let’s start with theory. A transformer in a photovoltaic system is not absolutely required from a physics standpoint. In certain technical conditions, it is possible to build a PV system without a dedicated transformer station. But those cases are the exception, not the rule.

When can a PV system operate without a transformer?

Installed capacity is up to 50 kW — still qualifies as a micro-installation, so direct low-voltage (LV) grid connection may be allowed

You have access to an internal LV switchboard (not part of the DSO infrastructure) — for example, expanding a factory’s existing internal grid

Low-voltage inverters (3x400 V) — so no galvanic isolation or voltage step-up is required

DSO accepts direct connection — which is often the most difficult part. Operators usually require isolation and voltage compliance with the grid

In such a configuration, instead of a transformer station, you must ensure:

proper protection devices

reactive power compensation

harmonic filtering (e.g. active filters)

continuous energy quality monitoring

But here’s the catch — very few installations meet all of these criteria simultaneously.

What could replace a transformer in a PV system?

In theory, a transformer can be "replaced" with a carefully configured system of inverters and filters. In practice, though, this is not really a substitution but a complete redesign. The inverters would need to ensure:

output voltage matches the grid (e.g. 3x400 V, ±10%)

harmonic distortion remains low (THDi < 4%)

operation without galvanic isolation (which requires DC-side grounding)

adaptation to variable load and reactive power demands

All of this increases the system’s complexity and cost. And often, it turns out that building a transformer station is actually the more economical choice. It’s not a paradox — it’s the result of the many roles a transformer plays in a PV system: voltage regulation, galvanic separation, harmonic filtering and protection against disturbances.

When is a transformer absolutely necessary?

When capacity exceeds 50 kW — the system qualifies as a small-scale installation and falls under strict grid rules

When connecting to a medium-voltage grid (15 or 20 kV) — a transformer is required, without exception

When galvanic separation is required by the operator — which is the case in most countries

When the system is far from the load center — for example, in a ground-mounted PV plant with no existing LV infrastructure

A transformer is not just a voltage step-up device. It is also a safety buffer that protects inverters from overvoltage and grid-side noise. It is what allows the system to meet the technical connection conditions — and without that, no grid agreement will be signed.

Conclusion — can you build PV without a transformer?

Yes, but only in specific setups. And usually only for smaller capacities, up to 30 to 40 kW. In every other case, a transformer is essential — not just because "rules say so," but because it determines:

user safety

grid operator approval

the quality of injected power

the long-term durability of your inverters

What transformer for a 50, 100 or 150 kW PV plant? Technical specs and real-life examples

You walk onto the construction site. PV tables are mounted, inverters are wired, the foundation for the substation is in place. Everything looks great — until you look at the transformer. It’s a stock 160 kVA unit with a 0.4/15.75 kV ratio. Sounds good? Maybe — but if your inverters output 800 V, that transformer could be a time bomb.

At Energeks, this is not theory. This is our daily reality.

What transformer for a 50 kW PV system?

For a 50 kW installation with 3x400 V inverter output, the typical transformer setup is:

63 kVA

0.4/15.75 kV or 0.4/20 kV ratio

ONAN cooling

Voltage regulation ±2 x 2.5%

Insulation class F

No-load losses up to 350 W

This configuration meets MV grid requirements, enables safe connection to the DSO switchgear, and helps compensate basic inverter-generated harmonics. And let’s be clear — even in small PV farms, the transformer is not just a “step-up box.” It stabilizes the entire system.

What transformer for a 100 kW PV system?

This is where things get serious — especially because of the increased peak current levels. For a 100 kW PV plant, we recommend:

125 kVA

0.4/20 kV or 0.8/15.75 kV ratio depending on inverter specs

Core rated for THDi up to 8 to 10%

Insulation class H for improved thermal endurance

No-load losses up to 600 W, load losses around 1.5 kW

A common question is: is 100 kVA enough for a 100 kW system? The answer is — only under ideal conditions. In practice, a 20 to 25 percent oversize margin helps maintain efficiency and system life, especially for projects expected to operate 15 to 20 years.

What transformer for a 150 kW PV system?

At this scale, any mismatch in specs can quickly compromise safety and grid compliance. A typical configuration:

160 to 200 kVA (most commonly 200 kVA)

0.8/15.75 kV ratio — necessary for 800 V inverters like SolarEdge or SMA CORE2

Amorphous or oversized conventional core

ONAN or AN cooling, depending on indoor or outdoor mounting

Voltage regulation ±2 x 2.5% or even ±5%

Harmonic resilience: THDi up to 12%

A frequent mistake? Using a 0.4/20 kV transformer with 800 V inverters. The result: inverter overheat alarms, voltage mismatch, and a drop in output by 8 to 10 percent versus expected production.

Does the transformer have to be bigger than the PV capacity?

This comes up almost as often as “can I save money on cables?”

In theory, the transformer can match inverter output exactly. In practice:

it should be oversized by 10 to 15 percent

account for cable losses

allow for short-term overloads on sunny days

give room for future expansion

So for a 150 kW PV plant, a 200 kVA transformer is not overkill. It’s standard good practice that ensures stability and compliance.

Step-by-step transformer selection for a PV farm

Check inverter output voltage — is it 400 V or 800 V?

Choose the right transformer ratio — based on grid voltage (15.75 or 20 kV)

Account for THDi — if above 8 percent, choose a unit with reinforced low-voltage windings

Verify short-circuit level of the MV grid — transformer withstand must match it

Select insulation and cooling — class H and ONAN are a solid baseline

This is not a spreadsheet. It’s a construction site. A transformer for a 50, 100 or 150 kW PV plant has to withstand 365 days of work per year, with variable loads, under real grid conditions. A poor choice can cost you not only your warranty — but the profitability of the entire system.

Why your PV transformer overheats: 5 mistakes that only show up after commissioning

On paper, everything looked perfect. Inverter output: 100 kW. Transformer: 125 kVA. Manufacturer efficiency: 98.4 percent. Sizing margin: 25 percent. Spreadsheet says the return on investment is five years. The investor is happy. The installer too.

Then comes real life. Inverters start disconnecting around noon. Voltage at the low-voltage busbar swings unpredictably. Transformer temperature hits 95°C on a warm afternoon — and that’s not even at full load. What went wrong?

A transformer is not a number — it’s a behavior in a system

A PV transformer is a dynamic component. It operates in a system where everything changes hourly — irradiance, load, grid voltage, harmonic content. And a spreadsheet knows nothing about clouds, surges, or inverter behavior.

Here are the five most common mistakes that do not show up on the drawing board — but appear after the PV plant goes live.

1. Transformer too small for real-world overproduction

A 100 kW PV system can easily generate 110 to 115 percent of its nominal power on sunny days. That’s normal — panels are often rated above STC and optimized for extra output. But a 125 kVA transformer with no headroom for overloads? That’s a bottleneck.

Symptoms:

inverter disconnections during peak sun

transformer overloads and thermal alarms

higher-than-expected load losses

What to do: if you’re asking should the transformer be larger than the inverter power, the answer is yes — smart oversizing (10 to 15 percent) is an industry standard, not a luxury.

2. Wrong voltage ratio

One of the most frequent field errors. Your inverters output 800 V, but someone orders a 0.4/15.75 kV transformer because “that’s what we always use.” The result? Voltage mismatch, inefficient operation, overheated windings, and inverter faults.

Fix: always verify your inverter AC output. SMA CORE2 and SolarEdge SE100K require 0.8/15.75 kV, not 0.4 kV.

3. No resilience to harmonics

PV inverters generate non-sinusoidal current. THDi levels can easily hit 8 to 10 percent, especially at partial load. Standard transformers rated for <3 percent THDi cannot handle this distortion.

Consequences:

overheating of core and windings

higher iron and copper losses

shorter insulation life span

What to look for: choose a PV-specific transformer with low-loss core material, reinforced windings, and thermal headroom for harmonics.

4. Ignoring the short-circuit level of the MV grid

Designers focus on transformer size and ratio but forget to check short-circuit levels at the point of connection. If the MV grid can deliver 16 to 20 kA and your transformer is only rated for 12.5 kA, it may fail on the first switching surge.

Risk: winding deformation or insulation breakdown due to undervalued withstand strength.

Pro tip: always ask your DSO for fault level data and confirm that your transformer’s mechanical and dielectric specs match.

5. No voltage regulation on the primary side

MV grid voltage is not a constant. It fluctuates — especially in regions with high renewable penetration. If your transformer has no primary-side regulation taps (±2 x 2.5 percent), matching inverter output to grid voltage becomes guesswork. Inverters do not play well with guesswork.

Outcome: inverters disconnect due to overvoltage, poor power quality, rejected compliance tests.

Recommendation: voltage regulation on the MV side is low-cost insurance for long-term grid compliance and uptime.

What to verify before you switch on your PV transformer

Is the transformer rated with enough margin for real-world peaks?

Is the voltage ratio compatible with the actual inverter output?

Can the core and windings handle high THDi?

Does the withstand rating match the fault level of the MV grid?

Is there voltage regulation on the MV side?

Because a PV transformer that looks fine on paper can fail in real life by week one. And instead of ROI, you’re looking at RMA.

Dry or oil transformer? What pays off — in the field, in a container, or inside a facility

If there is one question that keeps coming up in PV investment discussions, it is this one: “Should I go with a dry or an oil-immersed transformer for my solar farm?” It sounds simple enough. But the answer depends on many variables — and what seems cheaper at first is not always better in the long run.

Although datasheets for both technologies may look similar, real-life working conditions tell a different story. Ambient temperature, humidity, installation location, cooling capacity, and daily load profile all shape performance. And the wrong choice here? It will show up not on day one, but in year two — when your inverters start to complain.

Oil-immersed transformer — the workhorse of containerized and field-mounted PV

Let’s begin with the classic solution: the ONAN (Oil Natural Air Natural) transformer. This is the most common choice for containerized substations and pole-mounted systems used in open-air PV farms.

Why it works:

Superior cooling performance — the oil bath stabilizes temperature during sustained output

Better tolerance to overloads — ideal for high midday peaks

Lower cost at higher power levels — especially above 160 kVA

Greater harmonic resilience — oil-immersed cores handle non-linear loads more effectively

An oil transformer is a long-term, outdoor-ready solution, especially in regions with wide temperature swings from winter to summer. It fits perfectly in prefabricated container stations, ensures galvanic isolation, and allows for relatively easy servicing.

Field example:

A 150 kW ground-mounted PV installation using SMA CORE2 inverters (800 V AC) was paired with a 200 kVA ONAN transformer, 0.8/15.75 kV ratio, insulation class H. After two full seasons, the system remained stable, cool, and fully compliant — no shutdowns, no alarms, no complaints.

Dry-type transformer — clean, quiet, and safe for indoor solar systems

The dry-type resin-insulated transformer (AN) is the go-to choice when the substation is located inside a building — a warehouse, a manufacturing hall, or a commercial facility with rooftop PV.

Key advantages:

No oil, no risk of leakage — no containment basin needed

Environmental safety — easier to pass fire safety inspections

Lower noise levels — typically 50 to 55 dB, ideal near offices or equipment

Compact footprint — can be installed in technical rooms with limited space

However, dry transformers are not perfect. They do not handle overloads as well, are more sensitive to humidity, and rely entirely on passive cooling, which can be insufficient in higher power classes unless additional ventilation is installed.

Case study:

A rooftop PV system of 100 kW on a production facility used a 125 kVA dry-type transformer, 0.4/20 kV. Thanks to the quiet operation and lack of oil, the unit was installed just a few meters from occupied office space, with no special fire separation required. The result? Fast commissioning and zero complaints from facility management.

Oil or dry? Choose based on where it lives

Here is how to compare the two, not on paper — but where they will actually operate:

Installation site

Oil transformer: outdoors, in container stations

Dry transformer: indoors, in technical rooms or warehousesCooling performance

Oil transformer: very efficient, natural circulation

Dry transformer: moderate, passive cooling onlyOverload tolerance

Oil transformer: high

Dry transformer: mediumContainment needs

Oil transformer: yes — spill basin or protective barrier

Dry transformer: noneNoise levels

Oil transformer: 60 to 65 dB

Dry transformer: 50 to 55 dBHumidity resistance

Oil transformer: high

Dry transformer: lowerCost above 160 kVA

Oil transformer: lower

Dry transformer: higher

Don’t ask “which is better” — ask “where will it work?”

If your PV installation is located in an open field or a prefabricated container substation, an oil-immersed transformer is the better option. It offers flexibility, strength, and better thermal performance.

If you are building inside a facility or near office areas, and environmental or acoustic limits are a factor, then a dry-type transformer is often the only viable solution.

Both have their place. What matters is selecting the right one for your project’s specific context, not just what’s in stock.

A transformer is a strategic choice — not just an electrical detail

A transformer may not be the most visible part of your PV system. But it is one of the most consequential. It affects energy quality, uptime, compliance with the grid operator, inverter durability, and — ultimately — the financial performance of your investment.

Whether you are designing a 50 kW micro-installation or scaling up to a 150 kW rooftop or ground-mounted PV plant, choosing the right transformer is a decision that pays off for years. It is not just about matching ratings. It is about building a system that works — every day, every season, with zero surprises.

At Energeks, we work with designers, installers, and investors across Europe who want smart, field-tested energy solutions — not catalog copy.

If you want to:

consult a transformer selection with one of our engineers

check the availability of PV-ready dry or oil models

compare setups for rooftop, field, or container-based stations

visit our current offering here:

🔗 energeks.com/offer

And if you value honest engineering stories, real-life case studies, and technical wisdom that goes beyond datasheets — we’d love to connect with you on LinkedIn.

Let’s keep building solar the right way — with focus, care, and a long-term mindset.

Thank you for reading. If you found this helpful, feel free to share it or reach out.

We’re always happy to exchange ideas with those who treat energy like it matters.

Sources:

NREL.GOV: Inverters: A Pivotal Role in PV Generated Electricity

IEC 60076-1:2011, Power transformers - Part 1: General

Photo Cover: Trinh Tran pexels/191284110-14613940

How gas laws help understand DGA and predict problems before smoke appears (literally).

Dive into a world where gas tells the truth about the condition of multimillion-dollar investments. Discover the laws that are neither magic nor art—but pure physics.

If you work with transformer diagnostics, design substations, or manage energy infrastructure, understanding the basic gas laws can transform your approach to DGA—from intuitive to scientifically precise.

And that difference can save millions—not through "cost cutting" but through more accurate technical decisions.

Why are we talking about gas laws?

DGA (Dissolved Gas Analysis) is more than just “gut feeling and belief.” It’s the analysis of gases dissolved in transformer oil that can detect microscopic changes before a failure occurs.

But to truly understand what these gases are telling us, it’s worth starting with the physical laws that govern their behavior.

The ideal gas is not a myth. Even though reality is more complex, the ideal gas law equations provide a starting point for understanding diffusion, partial pressure, and equilibrium in the oil–gas system.

What exactly is Dissolved Gas Analysis (DGA)?

Dissolved Gas Analysis, or DGA, is a diagnostic method used in oil-immersed transformers. Its goal is to detect trace amounts of gases produced by thermal or electrical faults.

These gases dissolve in the insulating oil and serve as “fingerprints” of different types of degradation—before anything becomes visible to the naked eye.

Which gases are analyzed in DGA?

The most commonly monitored are seven key gases:

Hydrogen (H₂) – indicates early partial discharges and corona,

Carbon monoxide (CO;)

and carbon dioxide (CO₂) – linked to the degradation of insulating paper,

Methane (CH₄);

and ethane (C₂H₆) – signs of oil overheating,

Ethylene (C₂H₄) – higher temperatures, often associated with hot spots,

Acetylene (C₂H₂) – a marker of electrical arcing (the most dangerous type of fault).

What are the standards and gas tests?

ASTM D3612 is an international standard defining methods for extracting and measuring gases from transformer oil. It is complemented by standards like IEC 60567 and IEC 60599, which classify fault types based on gas ratios.

There is also frequent mention of the “three gas tests” in DGA:

Gas ratio test (Rogers Ratio or Dornenburg) – comparing ratios of selected gases,

Duval Triangle – a visual method for classifying faults based on three dominant gases,

Threshold test – assessing whether the concentration of a specific gas exceeds defined alarm limits.

1. The ideal gas law – the foundation of it all

In the world of transformers, where precision can mean millions, the ideal gas law is not just a school formula—it is the foundation upon which the entire logic of Dissolved Gas Analysis (DGA) is built.

The state equation:

PV = nRT

can be treated as the mathematical DNA of gas behavior inside a transformer. And although a transformer is not a vacuum flask in a lab, its interior—especially the oil–gas system—operates according to the same physical principles.

What do the symbols mean?

P – gas pressure: how strongly the gas "pushes" against its surroundings.

In a transformer, this refers to the partial pressure of individual gases, either dissolved or above the oil surface.

V – the volume the gas occupies. Even when gases are dissolved in oil.

Their molar volume plays a role when estimating the amount of gas produced.

n – number of moles of gas.

This is key to understanding how much hydrogen, methane, acetylene, or carbon oxides were generated in a reaction.

R – the gas constant. Constant, yet not to be ignored.

A universal value that connects all variables into one logical framework.

T – temperature. Often non-uniform in transformers.

"Hot spots" can locally reach up to 200°C.

How does it work in practice?

Let’s assume a microscopic amount of acetylene forms due to a short circuit. Measuring its concentration in the oil is one thing. But only by knowing the temperature in the affected area and the pressure conditions can we calculate how much gas actually formed.

More importantly—does the amount indicate temporary overheating, or long-term degradation of cellulose?

The ideal gas equation lets us "go back in time"—drawing conclusions about causes based on the effects, i.e., the detected gases.

The transformer as a chemical reactor

Think of a transformer as a closed system, where every change in temperature or volume affects the state of gases.

Overheating increases T, which—if the volume is constant—increases P.

That’s why gas measurements must be correlated with temperature data. Without that, interpreting DGA would be like forecasting the weather by looking at clouds—too many unknowns.

2. Henry: how much does a gas “like” to dissolve?

Imagine a cold Coca-Cola straight from the fridge.

You open it and hear a hiss—that’s carbon dioxide escaping from the liquid. Now leave that same bottle in the sun. The result? The gas escapes faster, and the drink goes flat.

Exactly the same mechanism works in transformers. It’s governed by Henry’s law, one of the most underestimated yet essential phenomena in DGA interpretation.

What does Henry’s law say?

In its simplest form:

C = kH ⋅ P

C – concentration of gas dissolved in the liquid (mol/m³)

kH – Henry’s constant, depending on gas type and temperature

P – partial pressure of the gas above the liquid

In practice, this means that the higher the gas pressure, the more will dissolve in the oil. But! That’s only half the story—because Henry’s constant decreases with temperature, meaning the warmer it gets, the less gas can remain in the liquid.

How does this work in a transformer?

Imagine local overheating of cellulose insulation—CO and CO₂ are generated. These gases partly dissolve in oil and partly rise into the headspace. If the transformer’s temperature increases even slightly, the oil’s capacity to retain gas drops. As a result, more CO escapes into the “head,” and its concentration in the oil seemingly decreases—even though the degradation process may be intensifying.

Caution! This is a trap in interpretation. A lack of gas doesn’t always mean no damage—it might simply mean the gas has already escaped.

Every gas “prefers” something different

Different gases have different kH values:

Hydrogen (H₂) – very poorly soluble, quickly escapes from oil

Carbon dioxide (CO₂) – relatively soluble, “sticks around” longer

Acetylene (C₂H₂) – short-lived, but detectable in arc faults

Knowing these properties allows engineers to better assess whether a gas has just formed or if the sampling system recorded it with a delay.

Interpretation with physics in the background

In day-to-day DGA practice, it’s not only about knowing threshold values, but also understanding the physical context:

Oil temperature – was it stable in recent days?

Time since the event – did the gas have time to dissolve or separate?

Do online readings differ from lab samples?

Henry’s law doesn’t give a ready-made answer, but it shows that gas isn’t just a number—it’s a physical phenomenon reacting to a dynamic environment. And that understanding builds an edge in transformer condition analysis.

3. What happens when temperature rises?

Temperature is not just the background to processes inside a transformer—it’s their primary catalyst. It determines whether chemical reactions ignite like a spark or remain dormant. For DGA interpretation, understanding the role of temperature is fundamental. It directly affects how many gases are formed, how quickly they move, and how long they remain dissolved in oil.

Heat as the trigger for gas formation

Inside the transformer, temperature conditions vary. Of critical importance are so-called hot spots—local points of elevated temperature, sometimes exceeding 200°C. This is where:

Pyrolysis of cellulose insulation occurs (producing CO, CO₂)

Thermal breakdown of oil takes place (producing CH₄, C₂H₆)

Ethylene and acetylene form at extreme temperatures (above 500°C in arcing faults)

Rising temperature not only initiates gas-forming processes but also amplifies their intensity.

According to the Arrhenius equation:

k = A ⋅ e − Ea/RT

where:

k – reaction rate

A – frequency factor

Ea – activation energy

R – gas constant

T – temperature in Kelvin

The higher the temperature, the smaller the value of the exponential denominator, hence the faster the reaction. This means that even a slight increase in temperature (e.g., from 120 to 150°C) can exponentially accelerate gas production.

Temperature vs. gas solubility

High temperature not only creates gas—it also affects its behavior in oil. Back to Henry’s law: higher temperature means lower gas solubility in liquids. In practice, when the system heats up:

More gas escapes from the oil to the headspace

The dissolved gas concentration decreases—which may falsely suggest the “situation is improving”

Partial pressure above the liquid increases—affecting further secondary reactions

Interpretation pitfalls

DGA performed while the transformer is operating (e.g., on a hot day) can yield different results than the same analysis done after cooling. That’s why each reading should be compared with temperature data: from online sensors, thermal history, or ideally—from hot spot temperature estimates (HST).

Without this, we risk a misinterpretation:

Low gas concentration at high temperature does not necessarily mean no risk

Sudden gas increase after cooling may reveal previously hidden processes

Relationships worth knowing

Effective DGA diagnostics requires knowing not only standards, but also physical interdependencies:

Gas generation rate – increases exponentially with temperature

Solubility – decreases with temperature

Partial pressure – rises with temperature at constant volume

These three phenomena together create a dynamic system that cannot be understood solely through an alarm threshold table.

Only by accounting for the role of temperature can we see the full picture and anticipate possible fault development scenarios.

4. Dalton and the gas mixture

Unlike in a laboratory, inside a transformer we never deal with just one gas. Degradation processes produce a whole spectrum of compounds—from light hydrogen to complex hydrocarbons.

That’s why, instead of analyzing each gas in isolation, it’s important to understand how they behave collectively. Here, Dalton’s law becomes one of the key gas laws in the context of DGA.

What does Dalton’s law say?

Ptotal = P1 + P2+ ⋯ + Pn

This means that the total pressure of the gas above a liquid (such as in the transformer headspace) is the sum of the partial pressures of all its components.

Each gas contributes its “share” to the total pressure—proportional to the number of moles present in the mixture.

Why is this important? Because in a transformer, it’s this very gas mixture—and its changing proportions—that reveals the type and intensity of the fault.

The mixture as a fault fingerprint

By analyzing the gas mixture composition, we can identify dominant degradation mechanisms:

A predominance of hydrogen (H₂) and methane (CH₄) suggests partial discharges,

The presence of acetylene (C₂H₂) is a clear sign of arcing,

High levels of CO and CO₂ indicate cellulose paper insulation degradation,

Increased ethylene (C₂H₄) is typical for overheating.

Dalton’s law allows us to model how partial pressures vary over time.

This in turn helps detect whether any particular gas is increasing rapidly—potentially indicating an escalation of the fault before it becomes apparent in summary charts..

Gas escape dynamics

Each gas in the mixture has a different solubility coefficient (see Henry’s law), but Dalton’s law determines which gas escapes the liquid first.

Those with higher partial pressures (e.g., hydrogen) will reach equilibrium between the oil and gas phases faster—and disappear from the system more quickly.

This explains why laboratory samples don’t always reflect the full spectrum of gases that were present moments earlier.

The absence of a gas in the sample doesn’t necessarily mean it’s no longer present in the transformer—it may simply have diffused or been vented out earlier.

IInterpreting gas ratio changes

In practice, diagnostics often rely on gas ratio tests, such as the Dornenburg or Rogers methods. It is thanks to Dalton’s law that these methods make sense: they allow us to evaluate not only how much gas formed, but how the various components relate to one another.

A noticeable shift in the ratio of, say, C₂H₂ to CH₄ may indicate a change in the fault type—e.g., from overheating to arcing.

If, on the other hand, gas ratios remain stable while concentrations increase evenly—this suggests the same fault is simply progressing.

Practical conclusions

Don’t analyze gases in isolation—the context of the mixture matters,

Watch for ratio changes—they're more revealing than absolute values,

If a gas disappears from the sample—check the pressure, temperature, and sampling history. It may have simply left the system.

Dalton’s law offers a holistic view of the gas system—not just as individual indicators, but as a dynamic system where every change has causes and consequences.

5. Diffusion – gas never sleeps

Gases in a transformer are not passive indicators of faults. They are active, mobile particles that—even after the fault processes stop—continue to “live their own lives”—slowly spreading through the system, reaching equilibrium, vanishing from samples or appearing where they weren’t before. This is governed by diffusion, precisely described by Fick’s first law.

What does Fick’s law say?

J = −D ⋅ dc/dx

Where:

J – diffusive flux (amount of moles moving through a surface per time unit),

D – diffusion coefficient (specific for each gas and medium),

dc/dx – concentration gradient (difference in gas concentration across space)

In short: gas moves from where there's more of it to where there's less—and the greater the difference, the faster the movement.

What does this mean in practice?

There is no such thing as a “constant gas composition” in a transformer—especially in systems with a large oil volume. Even if the fault occurs in a single spot (e.g., a local short), the generated gases will slowly spread throughout the entire system.

If a sample is taken from a different location than the fault origin—the results may be underestimated.

If analysis is delayed—the gas may have already escaped or diffused, blurring the alarm signal.

The importance of time – DGA isn’t always real-time

What we measure in a sample is a snapshot of the system at that moment. But diffusion means the system is constantly changing—even after the gas-forming reactions have ceased. In practice, this leads to several key recommendations:

A measurement taken immediately after the fault gives a different profile than one taken a week later,

The smaller the transformer, the faster diffusion equalizes concentrations,

Online systems allow for dynamic tracking—classic lab analysis shows only the “averaged effect.”

Why does diffusion matter for interpretation?

Imagine a transformer where ethylene (C₂H₄) was generated due to overheating. As soon as the temperature drops, the gas-forming process stops—but the ethylene continues to move through the oil. If sampling is delayed, the gas will already be partially dispersed or even vented into the headspace.

The result? The measurement shows a lower concentration than what actually existed at the moment of the fault.

The same goes for hydrogen—very light, poorly soluble, and prone to rapid diffusion. If the measurement is not taken in time, hydrogen may be incorrectly interpreted as absent—even though it was one of the first fault indicators.

Practical conclusions

Interpret DGA considering the time and location of the sample,

Use online systems wherever possible—they give a more complete picture of the dynamics,

Understand that the absence of gas doesn’t always mean no issue—it might be the result of diffusion or escape.

Fick’s law helps us better understand how the system “cleans itself” of gases—and how quickly fault information can fade.

It’s physics at work—continuously—even when everything seems to have returned to normal.

Let’s interpret the data that matters

In a world where the speed of decision-making matters more than the number of decisions made, access to reliable data becomes one of the most important advantages. But data alone is not enough.

Only proper interpretation—based on physics, process understanding, and real-world experience—creates value that allows us to protect, optimize, and plan the future of power infrastructure.

That’s why today, instead of asking whether DGA “shows something,” we ask: what exactly does it show, and how can we act smarter because of it?

At Energeks, we believe that every network device—from transformers to energy storage—deserves the same level of precision as the most advanced IT systems. Diagnostics doesn't have to be a guessing game—it can be science-based, predictable, and transparent. And that’s precisely what understanding gas laws enables.

As one of Europe’s leading suppliers of medium-voltage transformers and transformer stations, we support our clients daily in making decisions with long-term technical, financial, and environmental consequences.

That’s why our portfolio continues to grow:

➤ Modern transformers and complete transformer substations

➤ Energy storage systems, inverters, and EV charging infrastructure

➤ Technologies for photovoltaic farms and the renewable energy sector—efficient, safe, and future-ready

We proudly support investors, designers, municipalities, and technology integrators in creating solutions that work not only today—but also tomorrow.

Technology is the tool. People and values are the direction.

Get in touch with us if you’d like to discuss your challenge—we’re here to share our experience and find the best solutions together.

And if you’d like to become part of our knowledge and inspiration network—join us:

➤ Connect with the Energeks community on LinkedIn

Thank you for being with us—together we are building an infrastructure that not only works, but… learns, adapts, and grows alongside you.

Source:

Transformers Magazine vol.12

Silence. Calm. Safety.

A transformer that doesn’t smell of oil, doesn’t drip onto the floor, and doesn’t demand special maintenance rituals. A dry-type transformer is not an alternative. It’s a decision rooted in logic, in the demands of modern infrastructure, and in the awareness of today’s investors.

Who is this article for?

For designers, integrators, operators, and investors looking for reliable solutions in demanding environments — without compromise.

What will you find below?

Why dry-type transformers win in so many projects

Where oil-based technology can’t deliver

What you gain as an investor

A list of buildings where resin has replaced oil

Estimated reading time: 5 minutes

Reason 1: A dry-type transformer where oil fails

Picture a space where air doesn’t circulate freely, where fans have limited reach, and access to equipment is restricted. A multi-kilometer subway tunnel. A historic church with frescoes on the ceiling. A server room buried in the basement of a class A+ office building. All of these places share one critical challenge: zero tolerance for risk.

Add to that a relative humidity exceeding 80%, dust or suspended particles in the air, plus legal restrictions related to fire protection and a lack of space for oil-based safety systems. In such environments, is an oil-immersed transformer — requiring leak detection systems, retention tanks, and carefully managed ventilation — really the best choice?

Not always.

Oil transformer technology has its niche — primarily in open-air high-voltage substations (GPZ) or wind farms, where space and cooling conditions are favorable. In places where fire protection systems per PN-EN 61936-1 can be implemented, and a potential oil leak poses no threat to people or the environment.

But in many real-world projects — from hospitals and metro lines to heritage buildings and modern residential complexes — priorities shift:

Human and asset safety — especially where vulnerable populations or crowds are present. Even the smallest risk of oil ignition is unacceptable.

High reliability with no servicing — for locations that are difficult or impossible to access, long-term maintenance-free operation is essential.

Limited space and ventilation — where cooling systems can’t be installed or compliance with oil transformer norms is simply not possible.

Aggressive environmental conditions — like steam, salt (in coastal areas), or chemicals (in industrial zones) that can degrade traditional insulation systems.

This is where the dry-type transformer with resin insulation steps in. It doesn’t need oil-based cooling. It eliminates leak risks. It doesn’t require retention tanks. And it performs in environments where other technologies fail. Its sealed, durable design and low maintenance requirements make it the go-to engineering choice wherever traditional oil-filled models can’t keep up.

Reason 2: A dry-type transformer design built for advantage

In the engineering world, it’s not just about efficiency — it’s about reliability and adaptability. A dry-type transformer is like an athlete ready to compete without warming up — compact, focused, and ready to deliver from the start. Its biggest strength lies in a resin-based design that removes many of the typical weak points found in oil-filled units.

What does “dry” really mean?

It’s more than just oil-free.

A dry-type transformer uses no liquid insulation. Instead, it relies on epoxy or polyester resin applied directly to the windings. This not only eliminates the risk of fire — it redefines the way installations are planned. No retention basins, no leak detection systems, no emergency procedures needed.

In practice, this means:

No leaks — even in the event of mechanical damage

No vapor emissions — so no toxic fumes in enclosed spaces

No fire hazard from fluids — lowering fire protection requirements in the facility

A technology that breathes easy

Dry transformer windings are typically made from copper or aluminum wire, then vacuum-impregnated or cast with layers of resin (VPI – Vacuum Pressure Impregnation or CRT – Cast Resin Technology). The result is a build that is:

Moisture-resistant (up to 100% relative humidity)

Mechanically robust — won’t crack or deform

Electrically stable — with insulation strength up to 20–36 kV

Special versions are also available with anti-corrosion protection or electrostatic shielding, ideal for industrial environments with high salt or dust levels.

Silence that matters

Thanks to their compact build and vibration-dampening resin, dry transformers are significantly quieter than their oil-based counterparts. Noise levels typically stay below 50–60 dB, making them suitable for installations near people — in schools, offices, hospitals, or even museums.

This is a design that lets your building breathe — without noise, without oil smells, and without worries about system tightness.

A lightweight performer for demanding tasks

With a compact design and no need for external tanks or auxiliary systems, dry-type transformers weigh 20–30% less than oil transformers of the same rating. That’s a real advantage when installing on upper floors, inside vertical shafts, or in prefabricated energy containers.

Installation times can also be reduced by up to 40%, and fire safety approvals often become unnecessary.

Reason 3: What do you really gain?