Autumn-winter morning.

Dawn is just beginning to filter through the pine needles. On a white meadow, a transformer station stands alone, yet alive.

A light mist rises from the tank, like a breath in the frosty air. The engineer beside it looks up at the silvery vessel above the transformer. It is the oil conservator.

A metal safety shell that many mistake for an unnecessary accessory.

The question keeps coming back like a boomerang: does a transformer need an oil conservator?

In practice, the choice between an oil-immersed transformer with a conservator and a hermetically sealed design depends on the operating environment, load profile, diagnostic strategy, and requirements of the distribution system operator (DSO).

This article gathers both textbook knowledge and field experience in one place, clarifying concepts and showing the technical implications of each approach. We do not promote either option; instead, we compare them fairly so that the decision can be made predictably over the transformer’s entire life cycle.

At Energeks, we work with medium-voltage substations, transformers, and switchgears in diverse climatic and operational conditions. We see where hermetically sealed designs shine with simplicity and minimal maintenance, and where an additional compensating volume and traditional diagnostics provide operational peace of mind. This text distills those lessons into practical criteria.

The decision is not about conservator versus modernity.

It is about context versus coincidence.

A properly selected transformer reduces risk, costs, and the temperature of emotions during acceptance.

Who is this article for?

For designers, contractors, operators, and investors who want to select a transformer consciously, based on location, load profile, and maintenance policy. After reading, you will gain the knowledge needed to make better decisions, understand when an open oil circulation system makes sense, when a hermetically sealed unit is sufficient, how to plan diagnostics and maintenance, and how to avoid the most common mistakes.

Agenda

Oil conservator in a transformer: what it is and how it works

Transformer with an oil conservator: when to use it

Transformer with an oil conservator: when it is necessary

Selecting an oil-immersed transformer: service and operational best practices

Maintenance comparison: hermetically sealed transformer vs. transformer with conservator

Reading time: approximately 10 minutes

1. Oil conservator in a transformer – what it is and how it works

Imagine a transformer as the powerful heart of the electrical grid.

It pulses with current, responds to load fluctuations, heats up, and cools down. And like any heart, it needs space to beat in rhythm. For a transformer, that space is provided by the oil conservator – a modest cylindrical tank mounted above the main vessel.

It absorbs changes in the volume of oil as it expands in the heat and contracts in the cold.

Technically speaking, the oil conservator is a compensating reservoir connected to the transformer tank by a pipe through which the oil can flow freely. Inside, there is an air space, and between that space and the atmosphere operates a breather filter, also known as an air dryer – a small device filled with silica gel that removes moisture from the incoming air.

This setup allows the transformer to “breathe” without drawing in water, dust, or oxides.

It protects both the paper insulation and the oil from humidity, preventing premature aging.

If this description reminds you of anatomy, that is intentional.

A transformer with an oil conservator truly behaves like a living organism: during operation, it exhales heat and gases, and when it cools down, it inhales air. Without a conservator, it would also absorb moisture – and that moisture is to insulation what rust is to steel.

So, when someone asks “What is an oil conservator in a transformer?”, the answer is simple: it is a system that protects the oil from moisture and oxidation, extending its service life and maintaining stable electrical properties. In practice, the conservator often determines whether the oil will last thirty years or ten.

But its function doesn’t end with breathing.

The conservator also serves as a diagnostic indicator. It is equipped with a float-type oil level gauge, showing how the oil volume changes depending on temperature and load.

A sudden drop in oil level may indicate a leak, overheating, or an early sign of failure. For an experienced technician, this gauge is like the patient’s pulse – a small movement can reveal a great deal.

In higher-power units, the conservator also works together with a Buchholz relay, which detects gases generated by winding faults.

Thanks to this, the system can alert operators to a developing issue before it becomes critical.

In short: the conservator is the breath and the memory of the transformer.

And if someone asks, “When is a transformer with a conservator necessary?”, one might half-jokingly say: whenever you want your transformer to have healthy lungs and a long life.

A conservator is not always necessary

It is important, however, to maintain an engineering sense of balance.

A conservator is not a magical cure-all, and its absence does not signify a flaw in design.

Modern sealed transformers are not an inferior version; they represent an entirely different design philosophy.

Instead of the classic "breathing" provided by a conservator, their tank is completely sealed.

The changes in oil volume are compensated for by flexible corrugated walls or an internal elastic diaphragm.

This means the oil has no contact with the outside air whatsoever – it doesn't require a breather filter, it cannot absorb atmospheric moisture, and there is no need to monitor silica gel.

This solution proves its worth in environments that are clean and predictable: in indoor switchgear rooms, containerized substations, energy storage sites, and modern industrial facilities.

A sealed transformer requires less additional equipment, making it less susceptible to operator error and simpler to maintain. For many investors, this is a significant advantage – fewer inspections, fewer potential points for leakage, and lower operational costs.

Therefore, it is incorrect to claim that a transformer with a conservator is "better," and a sealed one is "worse."

They simply have different temperaments.

One is lik

e a marathon runner – built for endurance and resilience in changing conditions. The other is like a sprinter – compact and precise in a controlled environment.

A good engineer does not choose out of habit, but based on context: temperature, humidity, location, and the device's duty cycle.

So, if someone tells you a conservator is "mandatory," it's wise to smile and ask:

What is your actual operating environment?

Perhaps, instead of needing "lungs," what you truly need is a well-sealed construction that will operate reliably for its full 25-year lifespan in hermetic tranquility.

In the next part of this article, we will examine this with technical curiosity:

Where a transformer with a conservator truly makes sense.

Where a sealed design is the more rational choice.

We will compare how the two designs handle temperature, moisture, and oil aging.

We will also explore the real-world advantages of a conservator tank in practice and answer the question of when it is worth choosing one, and when a simpler sealed transformer will be the better option.

Because in engineering, as in life – more is not always better.

2. Transformer with an oil conservator – when to use it

The question “when to use a transformer with an oil conservator” is far from academic. In practice, the decision depends on the operating environment, the load profile, and the maintenance philosophy of the facility.

To clarify: the conservator is a compensating tank connected to the transformer vessel, allowing the oil to “breathe” as its temperature changes. The air entering from the outside passes through a silica gel breather, which captures moisture to prevent the degradation of insulation and the loss of dielectric properties in the oil.

Modern standards – including PN-EN 60076-1 and IEC 60076-7 – do not mandate a specific design type. Instead, they emphasize that the choice depends on operational conditions.

The selection criteria and the influence of environmental factors are discussed in detail in: IEC 60076-7: Loading guide for oil-immersed power transformers

And this brings us to the core of the matter: a conservator is neither better nor worse than a sealed design. It is simply a different method for managing the thermal expansion of the insulating oil.

Environments where a conservator makes sense

So, when is the environment favorable for a conservator?

Typically, in applications with significant temperature fluctuations—exceeding 50–60 °C annually—or where the thermal load changes dynamically. In these cases, the conservator acts as a pressure and temperature buffer, reducing mechanical stress on the main tank and enhancing the overall thermal stability of the system.

This solution is still commonly found in higher-power transformers (above 2.5 MVA) or those with on-load tap changers (OLTC), where easy diagnostic access and the use of classic Buchholz gas protection are important.

Furthermore, in locations with high humidity or significant microclimatic variability, a conservator can be beneficial—it helps limit moisture ingress into the system and slows down the oil aging process.

However, it must be emphasized: such a system requires oversight. If the breather filter is not regularly serviced, it can itself become a source of contamination, and its advantages are quickly lost.

Where a conservator is not needed

For the majority of modern installations, there is no longer a necessity to use a conservator.

Sealed transformers, with their corrugated tank walls or flexible diaphragms, compensate for oil volume changes without any contact with the external air. This reduces the need for servicing, eliminates breathers, and minimizes the risk of contamination. This is why in containerized substations, urban medium-voltage switchgear, at energy storage sites, PV farms, or within e-mobility infrastructure, the sealed design has become the default choice.

This is not a matter of trends, but of the operating environment.

In a temperate climate, with limited humidity and stable temperatures, a conservator offers no real advantage—it merely adds more components that require monitoring and maintenance.

In many contemporary projects, a standard transformer with a conservator is not so much an option as it is superfluous.

So when does a conservator come back into play?

When a project demands high thermal stability, easy diagnostic access, and compatibility with a Buchholz relay, the conservator remains a justified solution—not out of habit, but due to physics.

In high-power transformers, where the oil volume is measured in thousands of liters, temperature changes cause significant pressure differentials. The conservator then acts as a dampener—it absorbs the excess fluid during heating and returns it during cooling. It stabilizes internal pressure, relieves stress on seals, and slows the aging rate of the insulation.

The second area is diagnostics. A system with a conservator allows for easy visual or SCADA-sensor monitoring of the oil level, as well as simple oil sampling for Dissolved Gas Analysis (DGA). DGA is a crucial tool for assessing the condition of the paper-oil insulation, and in a sealed transformer, it can be more complicated as it may require breaking the tank's seal and risks exposing the sample to air.

The third aspect is gas protection—the Buchholz relay.

Mounted in the pipe between the main tank and the conservator, it reacts to gases generated by internal overheating or minor winding faults. Its operation is purely mechanical, requiring no external power—which is why it remains one of the most reliable protections for oil-filled transformers. In sealed transformers, where there is no gas cushion, the Buchholz relay simply has no place to function.

These requirements are found mainly in medium and large power network transformers, municipal infrastructure, and transmission substations, where durability, predictability, and rapid diagnostics are valued over absolute maintenance-freedom.

In these cases, the conservator is not a relic, but a functional element of the safety architecture.

In short then:

When to choose a transformer with a conservator?

When the project demands superior thermal stability and pressure management.

When full diagnostic control and easy oil sampling for DGA are required.

When compatibility with a classic, highly reliable Buchholz relay protection system is necessary.

And when to opt for a sealed transformer?

In the majority of modern projects located in temperate climates.

Where the top priorities are simplicity, cleanliness, and minimal maintenance.

This is not a competition between solutions, but a matter of matching the right technology to the specific context. For the engineer, the goal is not to champion one design over another, but to ensure that the transformer operates for a long time, reliably and safely, precisely in the environment where it is installed.

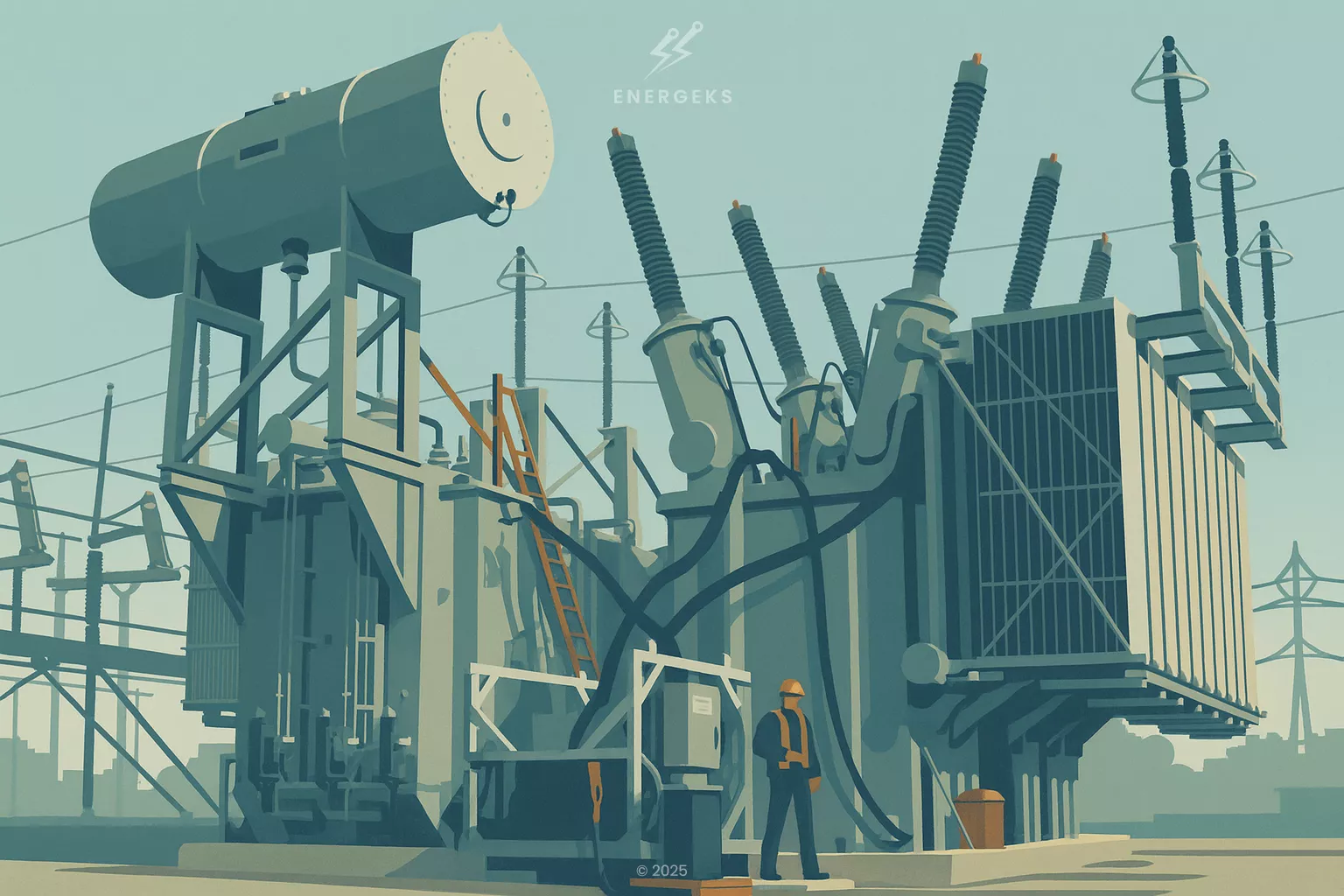

Transformer with conservator at a power station. The visible conservator tank is located above the vat, which allows for oil volume compensation and protection against moisture. The photo shows a robust industrial design used in medium and high voltage networks.

Photo Credit: Johann H. Addicks, via Wikimedia Commons (CC BY-SA 3.0).

3. A conservator for a transformer when is it necessary

There are certain scenarios where a conservator moves from being a simple option to an absolute necessity.

This isn't about a preference for classic designs or nostalgia for "old, reliable" solutions. It's about situations where the operating conditions, the specific demands of the operator, or the fundamental physics of the system mean that a sealed transformer simply won't suffice.

In this section, we will explore the circumstances that make a conservator a technical requirement, focusing on standards, operational practicality, and safety.

3.1 Requirements of distribution system operators (DSOs)

Distribution system operators across Poland and Europe are increasingly implementing technical specifications that clearly mandate the use of a conservator.

This typically applies to high power installations, with an operational lifecycle measured in decades think 30 years or more. For such critical assets, the focus shifts from the lowest initial investment to the total cost of ownership over the equipment's entire life. DSOs prioritize solutions that can be easily diagnosed, serviced, and whose behavior is predictable.

A conservator meets these criteria perfectly. With its oil level gauge, Buchholz relay, and the ease of drawing oil samples, it provides the operator with vital health information about the unit often before the alarm system is even triggered. It’s a design that offers transparency into the transformer's condition.

For a deeper dive into Buchholz relay systems and conservators, refer to the CIGRE Technical Brochure 445 – Transformer reliability survey

3.2 When the environment demands flexibility

The second category involves challenging climatic conditions significant temperature swings, prolonged periods of freezing cold or intense heat, substations without air conditioning, or those with limited ventilation. In these environments, a sealed transformer, while theoretically maintenance free, can be pushed to the limits of its mechanical resilience.

In a closed system, every rise in temperature causes a corresponding increase in internal pressure. Under sustained load, this continuous pressure cycling can lead to micro fractures or deformations in the corrugated tank walls.

In a sealed unit, even minor leaks are critical; they break the vacuum, expose the insulating oil to air, and trigger accelerated degradation of the paper insulation.

A conservator eliminates this core problem. Its function can be compared to a heart's atrium it acts as a buffer, absorbing the pressure pulsations and allowing the entire system to maintain a stable rhythm.

The oil is free to expand and contract without risking mechanical overload, and any air exchange with the atmosphere is carefully managed through a controlled, dry breather filter.

3.3 Longevity and parameter stability

In infrastructure projects like MV/LV distribution substations, industrial plants, municipal utilities, or large manufacturing facilities, the expected service life of the equipment can stretch to thirty years.

Over such a long time horizon, ease of diagnostics and long term thermal stability become far more critical than a minimal footprint or a "maintenance free" label.

A transformer equipped with a conservator enables planned oil quality checks, dissolved gas analysis (DGA), assessment of insulation aging, and a rapid response to the earliest signs of a fault. With a sealed transformer, many of these essential diagnostic activities require breaking the tank's integrity which is not only a costly procedure but also introduces the risk of human error during reassembly.

3.4 When simplicity is not enough

Seated transformer designs are excellent, but they do have their limitations.

In high temperature applications, where there are significant power losses and load cycles frequently approach maximum ratings, the lack of a pressure buffer becomes a genuine operational liability.

After several years, the cumulative effect of pressure differentials can weaken welds, cause distortions in the main tank, and lead to leaks that are, for all practical purposes, impossible to repair without replacing the entire unit.

A conservator serves as a straightforward mechanical safeguard against this exact scenario.

It is not needed for every installation but in applications where oil longevity and thermal stability are paramount to reliability, its inclusion is thoroughly justified.

3.5 Summary

A transformer with a conservator is necessary when:

The unit has a high power rating and a long expected service life.

It operates in an environment subject to large temperature variations.

It requires classic gas protection (Buchholz relay) or demands ongoing diagnostic capabilities.

The substation lacks air conditioning or active cooling systems.

The local distribution system operator (DSO) mandates a conservator system for safety and technical monitoring reasons.

Under these conditions, the conservator is far from an anachronism; it is a vital tool for stabilization a mechanical heart atrium that ensures the transformer continues to beat calmly and reliably for decades to come.

4. Oil transformer selection, service and good practices

Having decided, after analysing the conditions, requirements, and risks, that a transformer with a conservator is the right choice for our project, one question remains:

how do we use it to ensure it truly fulfils its purpose.

A conservator does not operate in a vacuum—it requires a measure of attention, regularity, and engineering discipline.

A well-maintained conservator is a guarantee of long oil and insulation life, whereas a neglected one is a source of predictable problems.

This section covers the four most critical areas that determine transformer reliability: maintaining the breathing system, monitoring oil level and quality, selecting the right conservator for the operating conditions, and day-to-day operation in the context of grid stability.

4.1 Maintaining the transformer's breathing

A conservator is an open system that interacts with the environment—this is why its breather, also known as an air filter with a dehydrating breather, is the first line of defence against moisture.

Filled with silica gel, it filters the air drawn into the transformer when the oil volume decreases due to a drop in temperature.

Over time, the gel gradually becomes saturated and changes colour—from blue or orange to pink. This is a simple but highly reliable indicator of when a replacement is needed.

Inspections of the dehydrating breather should be carried out every 6 to 12 months, and even more frequently in high-humidity environments. It is also important to check the condition of the connections and the cleanliness of the pipe connecting it to the conservator. Contamination can restrict airflow, which may lead to an increase in tank pressure and cause unwanted mechanical stress.

A good practice is to maintain a breather log—recording the dates of gel changes and its colour at the time of inspection.

In the long term, this helps identify correlations between seasonal operation and the saturation level of the desiccant.

4.2 Monitoring oil level and quality

The life of a transformer with a conservator follows the rhythm of its oil—the oil level and condition are the most transparent indicators of the system's health. Fluctuations in the level of around 5–10 percent are normal and result from temperature changes and load cycles.

Sudden drops, or a lack of change despite significant temperature differences, should raise concern—they could indicate a minor leak, a blockage in the pipe connecting the conservator to the main tank, or a damaged level indicator.

Once a year, it is advisable to conduct an oil test in accordance with the PN-EN 60422 standard. The key parameters are:

Dielectric strength

Water content

Acid number

Dissolved gas content (DGA)

If analysis indicates degradation, the oil can be processed through filtration or regeneration.

In cases of deep oxidation—a complete oil change will be necessary.

Regular testing not only extends the system's lifespan but also provides valuable diagnostic data for predictive maintenance.

For practical operational guidance on oil quality and replacement, an excellent resource is

IEEE Std C57.106-2015 – Guide for Acceptance and Maintenance of Insulating Oil in Equipment

4.3 Selecting a conservator for the environment and load

Not all conservators are the same.

In photovoltaic and electric mobility projects, the transformer load changes dynamically—in PV systems with sunlight intensity, and in EV charging stations with daily and nightly rhythms. Such variations cause frequent thermal cycles, which require a conservator with an appropriately selected capacity and air exchange efficiency.

In environments exposed to dust, salinity, or high humidity, breathers with a higher IP protection rating and replaceable filter cartridges should be used.

An alternative is conservators with an internal membrane or a nitrogen cushion system, which eliminate direct contact between the oil and air while retaining the ability to compensate for pressure.

Such solutions are increasingly used in infrastructure projects with heightened environmental requirements.

4.4 Good operational practices

The foundation of the system's longevity is routine observation—what one might call engineering common sense.

In practice, this means:

Checking the breather and the oil level indicator at least twice a year.

Inspecting the cleanliness of the conservator's housing and connections.

Measuring the top-oil temperature and comparing it with historical trends.

Documenting all inspections, even the most minor ones, in an operational log.

This is not bureaucracy—it is the life history of the equipment. This record allows for the prediction of component wear and the planning of replacements before a failure occurs.

4.5 Grid stability and smart maintenance

A transformer with a conservator does not require daily attention, but it thrives on rhythm and systematic care. Just a few minutes of observation and an annual review are enough to keep the system stable for decades. A well-maintained conservator is not a cost—it is an investment in peace of mind.

After all, its role is simple: to cushion thermal stress, maintain balance, and allow the entire installation to breathe.

Is a conservator a luxury or a necessity for grid stability? It's a question each medium-voltage substation answers for itself—usually at the moment when the network truly begins to breathe at full capacity.

5. Maintenance comparison: sealed oil transformer versus transformer with a conservator

At first glance, both devices look identical: a tank, bushings, radiators, and a thermometer.

Yet, their day-to-day operation represents two different worlds.

A sealed oil transformer is a closed, modern construction with corrugated walls that compensate for the thermal expansion of the oil. Everything happens inside—without air access, without gas exchange, and without a conservator. It is a solution designed with simplicity and operational cleanliness in mind.

The user does not need to check the machine's 'breathing'; they only monitor pressure, temperature, and the condition indicators for the oil.

The version with a conservator operates on a completely different rhythm.

This transformer breathes. The oil travels between the main tank and the expansion tank, and the air that enters the system passes through a breather filter filled with silica gel.

This seemingly minor detail acts as the transformer's lungs—it dries the air and prevents water vapor from condensing inside. However, it requires regular inspection, typically every 6 to 12 months, because moist gel loses its properties and can end up introducing contaminants into the system instead of protecting it.

A sealed oil transformer is, in essence, a self-sufficient system.

Temperature, pressure, and oil condition are all monitored by sensors like RIS2 or DGPT2.

The system signals anomalies but does not require "manual" oversight.

One could call it a minimalist transformer—designed for environments with stable operating conditions where cleanliness, a small service footprint, and the absence of air exchange are valued.

In contrast, a transformer with a conservator is a design for the engineer who likes to have everything under control.

The oil level indicator, the ability to take oil samples for DGA, the visible Buchholz relay float that reacts to the smallest amounts of gas—these are all features that allow for intervention before a fault fully develops.

In exchange for regular review, the conservator offers full transparency: the user sees how the oil behaves, knows its color, and can tell when something deviates from the norm.

The differences in maintaining these transformers are significant

A sealed transformer requires just one annual review, limited to reading key parameters and checking for leaks.

A transformer with a conservator needs a semi-annual ritual: assessing the color of the silica gel in the breather, checking the oil level, cleaning the housing, and potentially topping up the fluid.

But in return, it offers diagnostic depth—the ability to "read" the condition of the equipment almost like an EKG reading.

In summary, a sealed oil transformer is like a quartz watch: precise, sealed, and maintenance-free.

A transformer with a conservator, on the other hand, is like a mechanical chronograph: it requires care and attention, but it provides complete insight into its inner workings and rewards that care with longer, more predictable, and transparent operation.

Both solutions are excellent, each within its intended environment.

You choose the first when you prioritize peace of mind and minimalism.

You choose the second when you value a connection to the equipment, deep knowledge, and hands-on control.

After all, in power engineering—as in life—the goal isn't always to have less to do, but to know exactly what is happening beneath the surface.

Conclusions

After this journey through temperatures, humidity, and diagnostics, the conclusion is simple.

There is no inherently better or worse design in an absolute sense. It's all about selecting the right solution for the specific context.

A sealed transformer offers cleanliness and minimal maintenance for a stable environment.

A transformer with a conservator provides thermal flexibility, diagnostic insight, and classic gas protection where the elements can be unpredictable. The true advantage lies in a decision supported by data, lifecycle analysis, and an honest conversation about risks.

If you are facing this choice today, ask yourself three questions:

What are the temperature swings and humidity levels at the operating location?

How quickly and how often does the load change?

What diagnostic and protection strategy do you want to have for the years to come?

The answers will point you in the right direction more accurately than any marketing slogan.

Finally, a thought for the mind that appreciates concrete details:

What more reliably secures an investor's peace of mind?

Flawless installation of a sealed transformer where the climate is predictable?

Or a conservator with a well-executed maintenance plan where the weather and load profile dictate the rhythm?

This question will lead you to the right decision more often than a long list of arguments.

Collaborate with us!

For years, we have helped designers, contractors, and operators select solutions tailored to real-world operating conditions.

If you need support in the selection process, we will prepare a recommendation with technical justification and a risk calculation over the entire lifecycle.

Explore our offerings and check availability:

Oil immersed transformers Tier2, parameters and selection for environment and load profile

Energeks Oil Transformer OfferDry transformers, compliant with Ecodesign Tier 2, for facilities with high environmental requirements

Energeks Cast resin Transformers Tier 2 EcodesignOff-the-shelf delivery and an extended five-year warranty for selected models

Transformers Available Immediately, 5-Year Warranty

Want to stay updated with practical advice and case studies? Join our community.

Energeks LinkedIn Profile

We are grateful for your trust and the opportunity to be your partner in projects where safety, reliability, and sound judgment go hand in hand.

If you wish, we can refine this material for your specific investment or prepare an acceptance checklist for your chosen variant. We are here for you

References:

https://webstore.iec.ch/publication/2230 – IEC 60076-7: Loading guide for oil-immersed power transformers

https://www.e-cigre.org/publications/detail/642-transformer-reliability-survey.html – CIGRE Technical Brochure 445: Transformer Reliability Survey

https://ieeexplore.ieee.org/document/7442048 – IEEE Std C57.106-2015: Guide for Acceptance and Maintenance of Insulating Oil

Reviews

No reviews!