Spark gap in a medium voltage transformer – a guardian that sometimes looks guilty

Imagine walking into a prefabricated transformer substation on a foggy, humid morning. The air is dense, and in the background you hear the soft hum of a fan. You open the door to the medium voltage compartment, and your eyes are immediately drawn to one component – the spark gap.

It has dark streaks, burn marks, and uneven electrode coloration. If you have only seen new equipment before, you might instantly think: “We have a failure.”

However, the reality might be the complete opposite.

These marks do not necessarily indicate damage – very often they are proof that the spark gap has operated and protected the transformer from a dangerous overvoltage.

Just as a seat belt after a collision bears the marks of the strain it has absorbed, a spark gap after operation shows traces of the electric arc that saved the winding insulation.

Why are we writing about this?

At Energeks we work with medium voltage transformers in a variety of environments, from industrial plants to municipal facilities.

Many operators and investors come to us asking: “Is it normal for the spark gap to look burnt?” The answer is often yes – it is normal and even desirable, provided that the marks remain within the limits allowed by the manufacturer.

Our goal is simple:

To explain what a spark gap is, how it works, when it requires intervention, and how to service it so that the installation is protected at the highest level.

In this material you will find:

What exactly a spark gap is and the functions it performs

How the operation process works, from the occurrence of overvoltage to the dissipation of energy

Why marks appear on the spark gap and what they mean

The differences between a spark gap and a surge arrester

Criteria for distinguishing normal operating marks from actual damage

Inspection and maintenance procedures

The impact of environmental conditions on the spark gap’s condition

When replacement is necessary

The importance of operator education

The outlook for the future of overvoltage protection

Reading time: approx. 15 minutes

1. What is a spark gap in a medium voltage transformer

A spark gap in a medium voltage transformer is an overvoltage protection element that works like a safety valve for the power system.

Its construction is based on two or more electrodes separated by an air gap or a gas-filled gap.

Principle of operation:

Under normal operating conditions, the working voltage is lower than the breakdown voltage of the air in the gap, so the spark gap does not conduct.

When a sudden voltage surge occurs in the network (for example, as a result of lightning, switching operations, or line faults), the voltage between the electrodes exceeds the critical value – the so-called ignition voltage.

An electric arc forms, conducting the energy to the grounding system and protecting the transformer windings.

Standards: According to PN-EN 60099 and IEC 60099, the parameters of the spark gap must be selected so that the ignition voltage is sufficiently higher than the network’s operating voltage but lower than the insulation withstand level of the transformer.

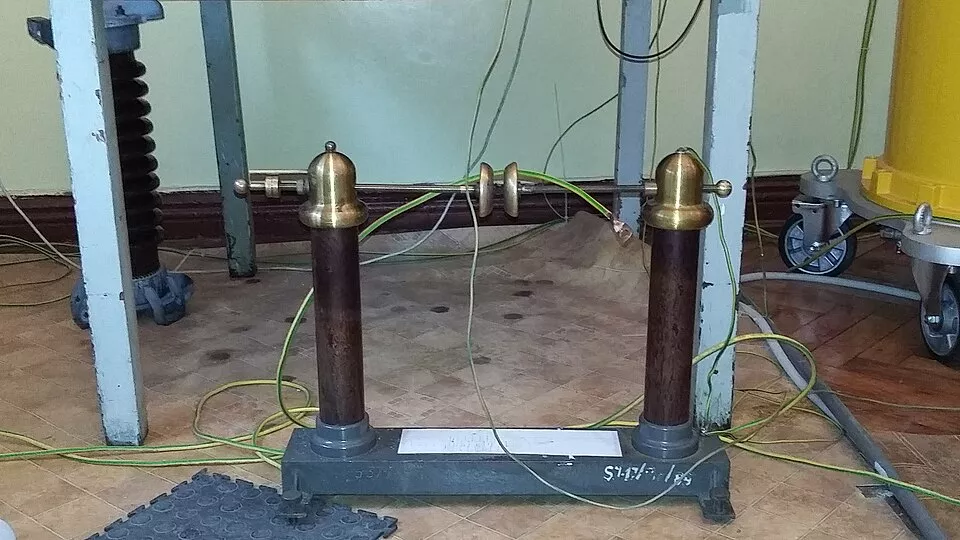

Laboratory spark gap with flat electrodes/CC: Wikimedia Commons

2. How the spark gap operates – from the occurrence of overvoltage to energy dissipation

The operation of a spark gap in a medium voltage transformer is an extremely dynamic phenomenon that unfolds within microseconds, yet it determines the safety of the device and often the entire substation.

It is worth following the process step by step to understand what actually happens in that small gap between the electrodes.

2.1. Occurrence of overvoltage

Under normal conditions, the network’s operating voltage is stable and remains well below the ignition voltage of the spark gap. Overvoltage occurs during a sudden rise in voltage, which may be caused by:

Lightning discharge (a lightning impulse can have a steep front of around 1.2 µs and an amplitude of hundreds of kV)

Switching operations in the network (switching large loads on or off, changing sections)

Short circuits in other parts of the network (back surge voltage spikes)

Ferroresonance in systems containing capacitances and inductances

When the voltage between the spark gap terminals increases and approaches the critical value, the initiation process begins.

2.2. Discharge initiation – ionisation of the medium

The medium between the electrodes (most often air or an inert gas in enclosed versions) acts as an insulator. However, after exceeding the so-called breakdown voltage, according to Paschen’s law, the gas molecules begin to ionise. Electrons accelerate in the electric field and, colliding with atoms, knock out additional electrons, creating an electron avalanche.

This is the moment when the resistance of the gap starts to drop rapidly. In practice, from the moment the ignition voltage is exceeded to full breakdown, only a few nanoseconds to several microseconds pass.

2.3. Breakdown and formation of the electric arc

Once the avalanche of ions and electrons forms a conductive path, breakdown occurs – an electric arc appears between the electrodes. The temperature in the arc channel rapidly reaches values of around 5000–6000°C.

In this state, the overvoltage current finds a path of minimal impedance toward the grounding system. Typical current values are:

For lightning impulses – tens of kiloamperes (e.g. 8/20 µs according to standards)

For switching surges – from several hundred amperes to several kiloamperes

2.4. Energy dissipation to grounding

The electric arc in the spark gap acts as a transport channel that carries the overvoltage energy from the medium voltage circuit to the grounding system. The quality and resistance of the grounding are crucial – high grounding resistance can cause dangerous step and touch voltages around the substation.

In professional installations, grounding with a resistance not exceeding 2–4 Ω is used for medium voltage substations, in accordance with PN-HD 60364 and PN-EN 50522 requirements.

2.5. Arc extinction and return to the idle state

After the excess energy has been discharged, the circuit voltage drops below the arc sustaining voltage. The plasma channel begins to deionise – ions and electrons recombine, temperature falls, and the gap between electrodes returns to its insulating state. The extinction time depends on factors such as:

Spark gap design (open, enclosed, tubular)

Pressure and composition of the medium

Cooling rate

2.6. Marks after operation – the “scars” of protection

After the entire process, the electrode surfaces bear the effects of the arc:

Localised burn marks at the initiation point

Microscopic material losses

Deposits of metal oxides and carbon

These are the very marks so often mistaken for signs of failure. In reality, in most cases they are evidence of effective protection.

3. Why marks appear on a spark gap and what they mean

Marks on a spark gap are a topic that often stirs discussion during transformer substation inspections. To the untrained eye, they may look like a sign of wear or damage. In reality, in many cases they are not only normal but even desirable – they indicate that the device has fulfilled its function and protected the transformer against overvoltage.

Where the marks come from

To understand why a spark gap bears “scars,” it is worth looking at the physical process that takes place during its operation. At the moment of overvoltage, the dielectric between the spark gap electrodes – most often air or a gas filling the housing – undergoes breakdown. An electric arc forms, and in its channel the temperature can reach 5000–6000°C.

Such high temperatures cause:

Microscopic evaporation of electrode material – metal atoms transition to a gaseous state and, after cooling, condense on nearby surfaces as a dark deposit

Metal oxidation – in the presence of oxygen and high temperature, dark-coloured metal oxides form

Pyrolysis of organic particles (if insulating materials are nearby), resulting in carbon deposits

Types of marks

Marks on a spark gap can take different forms – and their appearance provides valuable information about the device’s operating history.

a) Localised burn marks

These are small, dark spots where the electric arc was initiated. They can occur after just a single operation.

b) Extensive discolouration

Appears when the spark gap has operated several times in a short period. The electrode surfaces change colour due to repeated heating and cooling cycles.

c) Carbon or metallic deposits

Formed from particles torn from electrodes or contaminants present in the air. In substations located near industrial facilities or in coastal areas, such deposits may be more intense due to the presence of salt or dust.

d) Surface dullness

The effect of long-term operation, where many micro-damages alter the metal’s texture.

What the marks mean – interpretation

Not every mark is an alarm signal. In assessing the condition of a spark gap, it is important to distinguish between signs of normal operation and signs of actual wear.

Operational marks – proof that the spark gap has operated and fulfilled its function. These may include minor burn marks, discolouration, or a thin layer of deposit that can be easily removed.

Critical wear marks – cracks in the ceramic or polymer housing, deep electrode material losses, permanent conductive deposits that reduce the insulating gap and may cause uncontrolled flashovers at operating voltages.

Everyday comparison

A spark gap can be compared to brake pads in a car. Friction marks do not mean the pads need replacing – on the contrary, they prove the brake is working. Replacement is only necessary when pad thickness falls below the limit or structural damage occurs. Similarly, in a spark gap, discolouration and light burn marks are a normal “trace of action,” not a failure.

Impact of the environment on the appearance of marks

Marks may look different depending on the conditions in which the substation operates:

High humidity – promotes deposits with a more uniform, dark colour

Air salinity – in coastal areas, deposits may be thicker and more conductive

Industrial dust – causes grey or brown deposits, sometimes harder to remove

Why understanding mark interpretation is crucial

Misinterpretation can lead to two unfavourable scenarios:

Unnecessary replacement – generating costs and downtime even though the component still works correctly

Failure to replace – leaving a worn or damaged spark gap, which exposes the transformer to damage during the next overvoltage

We recommend documenting the spark gap’s condition during each inspection (photos, measurements).

4. Differences between a spark gap and a surge arrester

In the power engineering sector, these two terms are sometimes used interchangeably, which often leads to misunderstandings during inspections, spare part orders, or discussions with investors.

Although a spark gap and a surge arrester are functionally related – both are intended to protect equipment from the effects of overvoltage – their role, design, and operating scope are different.

Spark gap – a component, not a complete device

A spark gap is a single overvoltage protection component. It consists of two or more electrodes separated by an air gap or enclosed in gas. Its operation is simple and based on dielectric breakdown:

Under normal conditions, it does not conduct current.

When the ignition voltage is exceeded, a sparkover occurs and energy is diverted to the grounding system.

On its own, a spark gap cannot provide comprehensive protection against all types of overvoltage because it operates only when the ignition voltage threshold is exceeded. In medium-voltage transformers, it is most often used as an auxiliary element or in older designs.

Surge arrester – a complete overvoltage protection device

A surge arrester is a complete device that may include a spark gap as one of its components, but can also operate using other technologies – most commonly metal oxide varistors (MOV).

Types of surge arresters:

Spark gap type surge arresters – older designs where the spark gap is the main trigger element. Additional components (e.g. resistors) control current after operation and extinguish the arc.

Gapless surge arresters – modern designs based on zinc oxide varistors with a highly nonlinear characteristic: at operating voltage they conduct minimal leakage current, while during an overvoltage their resistance drops sharply, diverting energy.

Why spark gaps are still found in MV substations

Although new projects increasingly use gapless surge arresters, spark gaps are still present in:

Prefabricated transformer substations from the 1980s and 1990s

Systems undergoing phased modernisation (where the transformer has been replaced but not the entire MV equipment)

Installations with a limited budget, where simple protection is better than none

Cooperation between spark gaps and surge arresters

In some systems, spark gaps and surge arresters work together:

The surge arrester (e.g. MOV) responds to smaller, more frequent switching overvoltages

The spark gap acts as a “last resort” safeguard against very high overvoltages, for example from a nearby lightning strike

This tandem is particularly effective in environments with a high risk of lightning overvoltages.

Put simply – the spark gap is like a trigger, and the surge arrester is the entire protection system.

One is a component, the other is an integrated solution.

Understanding this distinction is essential for correctly interpreting equipment condition in a substation and making service decisions.

Spark gap and surge arrester, the difference explained in three sentences

A spark gap consists of two electrodes with an air or gas gap between them, which conduct only after a voltage breakdown and extinguish after the overvoltage ceases.

In the power industry, a surge arrester is most often a sparkless zinc oxide arrester in a polymer housing. It acts as a non-linear surge clamping element and returns to high resistance after a surge.

These terms should not be confused with “lightning rod.”

A lightning arrester protects equipment and lines, not the building itself.

5. Criteria for distinguishing normal operational marks from actual damage

During an inspection of a prefabricated transformer substation, many people, when seeing dark streaks, burn marks, or deposits on a spark gap, automatically assume the component is damaged. In reality, proper assessment requires looking not only at colour and appearance but also at geometric parameters, material condition, and operating history. In the power industry, several precise criteria are used to distinguish a “trace of operation” from a “sign of failure.”

Visual inspection – the first assessment filter

The basic step is to inspect the spark gap in good lighting, preferably using an inspection torch.

Normal operational marks:

Small, localised burn marks at arc initiation points

Slight discolouration of electrode surfaces

A thin deposit layer, easy to remove during cleaning

Damage indicators:

Cracks in ceramic or polymer housing components

Mechanical deformation of electrodes

Melting with visible depth to the naked eye

Electrode gap measurement

Each spark gap has a manufacturer-specified nominal distance between electrodes, which is critical for the ignition voltage.

Permissible tolerance is usually ±0.1–0.3 mm depending on the model

If the gap has decreased due to erosion or deposits, ignition voltage may drop below operating value, risking uncontrolled operation

If the gap has increased (e.g. due to mechanical damage), the spark gap may fail to operate in time, exposing the transformer to insulation breakdown

Condition of insulating surfaces

In open spark gaps, the insulation is air, but ceramic or polymer housing parts act as supports and spacers.

Normal condition:

Light surface deposit, removable

No visible losses or cracks

Failure condition:

Cracks running through the full thickness of the insulator

Traces of surface flashover (characteristic dark “tracking” marks along the insulator)

Type and structure of deposits

Deposit forms from condensed electrode material and airborne particles.

Safe deposit – thin, dry layer, non-conductive, easily removed with a dry cloth or antistatic brush

Risky deposit – thick, compact layer that may have conductive properties (especially in high humidity), potentially causing leakage currents and premature operation

Operating history and number of operations

Some spark gap models (especially in integrated arresters) are equipped with an operation counter. A value close to the maximum allowed indicates that the component is nearing end-of-life, even if it looks fine. In spark gaps without a counter, photographic documentation from previous inspections is essential to track deterioration over time.

Leakage resistance measurement

Advanced inspections may include measuring insulation resistance between electrodes at a DC test voltage (e.g. 500 V DC).

Values in the hundreds of megaohms are typical for a healthy component

A drop below several dozen megaohms may indicate conductive deposits or microcracks

Normative criteria – when to declare a failure

Standards such as PN-EN 60099 and IEC 60099 state that an overvoltage protection element should be considered defective when:

It fails to meet the declared ignition voltage in a control test

It has mechanical damage that may affect operational safety

It shows a permanent drop in insulation parameters

A practical rule often applied at Energeks:

If the mark can be removed and the component retains its geometric and insulation parameters – it is a normal operational effect.

If the mark is permanent and parameters deviate from standard – it is a sign for replacement.

6. Procedures for inspection and maintenance of a spark gap in an MV transformer

Regular inspection and proper maintenance of spark gaps in medium voltage substations is one of the simplest yet most effective ways to extend transformer lifespan and ensure continuity of power supply. Neglect in this area can result not only in costly failures but also in safety hazards for the operating personnel.

We recommend implementing a structured inspection procedure.

1. Preparation for inspection – safety first

Before performing any work on the spark gap, you must:

Disconnect the substation from the power supply in accordance with facility procedures.

Confirm de-energized status using a certified voltage detector.

Ground and short the MV circuits if required by DSO procedures.

Ensure the worker has personal protective equipment (electrical insulating gloves, safety glasses, helmet, flame-resistant clothing).

2. Visual inspection – the first stage of diagnostics

Check the condition of the electrodes for discoloration, burn marks and deformations.

Assess the insulator surface (ceramic, polymer) looking for cracks, scratches, or signs of surface tracking.

Analyse deposits to determine whether they are dry and easy to remove or compact and potentially conductive.

Energeks tip: use an inspection flashlight with a narrow beam to better spot microcracks and surface irregularities.

3. Measuring the electrode gap

Use a caliper or feeler gauge.

Compare the measurement with the value specified in the technical and operational documentation (DTR).

If the gap is smaller than the nominal value by more than 0.3 mm, cleaning or replacement is necessary.

An excessively large gap (for example after mechanical displacement) may prevent timely operation.

4. Cleaning

Perform cleaning only when the spark gap is dry and de-energized.

Use a dry, soft antistatic brush or a microfiber cloth to remove deposits.

For stubborn deposits, use isopropyl alcohol (IPA) applied to the cloth, never directly on the spark gap.

After cleaning, the element must be completely dry before re-energizing.

5. Photographic documentation

Take photos from three perspectives: front, side, and electrode detail.

Mark the date, substation number, and field number.

Compare with previous photos to determine the rate of degradation.

Why this matters: a visual history of the component allows predicting the replacement time before a failure occurs.

6. Measuring electrical parameters (optional)

For spark gaps sensitive to deposits, insulation resistance can be measured:

Set the meter to a test voltage of 500 V DC.

Above 100 MΩ – very good condition.

Below 50 MΩ – additional cleaning or replacement is required.

7. Replacement criteria

The spark gap must be replaced if:

it has cracks or mechanical damage,

the electrode gap deviates from the nominal value and cannot be corrected,

conductive deposits remain after cleaning,

insulation parameters have dropped below acceptable limits.

8. Inspection schedule

Substations in normal environments – inspection every 12 months.

Environments with high dust or salinity – inspection every 6 months.

Critical substations for power continuity – additional inspections after each storm or network failure.

9. Best practices

Maintain an inspection log with notes on condition, service actions, and measurements.

Use original spare parts in accordance with DTR.

Train personnel to interpret operational marks to distinguish them from faults.

7. Impact of environmental conditions on the condition of the spark gap

The effectiveness of a spark gap depends not only on manufacturing quality and correct installation but also on the environment in which it operates. A prefabricated transformer substation can be located in very different conditions – in the city center, next to an industrial plant, at a seaport, or near an open-pit mine. Each location presents different challenges for the spark gap.

Humidity and condensation

Mechanism of influence: High air humidity, especially combined with low temperature, leads to condensation of water on insulator and electrode surfaces. Water conducts electricity (especially with dissolved salts and contaminants), so a thin moisture layer can reduce the sparkover voltage.

Effects:

premature spark gap operation under normal working conditions,

formation of mineral deposits after water evaporation,

accelerated electrode corrosion.

Service recommendations:

regular inspections during periods of large temperature fluctuations,

checking substation ventilation,

use of hydrophobic coated elements in high humidity environments.

Saline air (coastal zones)

Mechanism of influence: Microscopic salt particles carried by sea wind settle on insulator and electrode surfaces. Salt is highly hygroscopic, attracting moisture from the air and forming a thin conductive layer.

Effects:

reduction in sparkover voltage by up to several dozen percent,

increase in leakage currents,

formation of persistent deposits that are difficult to remove.

Service recommendations:

clean spark gaps at least twice as often as in inland substations,

use enclosed or shielded designs,

periodically rinse components with demineralized water combined with drying.

Industrial dust

Mechanism of influence: Dust from industrial processes (cement plants, metallurgy, coal-fired power plants) settles on substation components, including spark gaps. Many of these particles have conductive or semiconductive properties.

Effects:

increased frequency of operation under moderate switching surges,

higher risk of surface tracking,

accelerated electrode wear from microscopic abrasive particles.

Service recommendations:

use air filters in substation ventilation,

clean spark gaps every 6 months or more frequently during intensive production periods,

inspect insulator surfaces for microdamage.

Agricultural environments and organic dust

Mechanism of influence: Near agricultural processing plants, grain dryers, or farms, the air contains organic particles. These may include fats or sugars that, once deposited on insulators, form a sticky layer attracting dust.

Effects:

formation of high-viscosity layers that are difficult to remove,

localized conductivity under high humidity conditions,

accelerated contamination of insulating surfaces.

Service recommendations:

perform chemical cleaning with mild degreasing agents (with caution),

carry out regular inspections during periods of intensive agricultural work.

Extreme temperatures

Mechanism of influence:

High temperatures may cause thermal expansion of components, slightly changing the electrode gap.

Low temperatures increase the risk of condensation and slow down moisture evaporation.

Effects:

in hot climates – potential accelerated aging of protective coatings,

in cold climates – higher risk of temporary drops in sparkover voltage.

Service recommendations:

adjust inspection schedules to seasonal weather conditions,

use materials resistant to UV and temperature fluctuations.

Why the environment must be considered in the service schedule

There is no single universal inspection interval for all substations – local conditions can shorten the required interval by as much as half.

We recommend the following approach:

Set the maintenance schedule after analysing location, history of spark gap operations, and grounding resistance measurements.

8. When to Replace a Spark Gap

A medium-voltage transformer spark gap can operate reliably for many years if it is correctly selected, installed, and maintained. However, like any electrical component, it undergoes aging and wear, and eventually its parameters will fall outside the manufacturer’s specified range. At that point, continued operation becomes a safety risk for the entire installation.

Most common reasons for replacement:

Mechanical damage – cracks in the ceramic or polymer housing, broken or deformed electrodes, or loosened mounting hardware. Such defects can lead to uncontrolled arc discharges or loss of mechanical stability.

Loss of geometric parameters – a change in the electrode gap beyond the tolerance specified in the technical documentation (typically ±0.3 mm) alters the ignition voltage. A smaller gap can cause premature operation, while a larger gap may prevent timely response to overvoltage.

Excessive electrode wear – repeated operation causes erosion and material loss, leading to pitting and rounding of sharp edges.

Permanent conductive deposits – industrial dust, salt, or corrosion products that continue to reduce resistance between electrodes even after cleaning. In humid environments, they can create conductive paths even at operating voltage.

Loss of insulating properties – insulation resistance dropping below the recommended value (e.g. <50 MΩ), often caused by microcracks or permanent contamination in the material structure.

Replacement criteria according to PN-EN 60099 and manufacturer documentation:

ignition voltage deviation greater than ±10% from nominal value during testing,

exceeding the maximum number of operations specified in the documentation,

mechanical damage affecting operational safety,

insulation parameters below acceptable limits.

Why service history matters

Two spark gaps may look identical but be in completely different technical condition. Keeping a maintenance log – including inspection dates, number of operations, measurement results, and photos – allows accurate prediction of the replacement point and avoids both premature and overdue replacement.

The economic rule is simple: the cost of replacing a spark gap is negligible compared to the potential cost of repairing or replacing a transformer damaged due to lack of surge protection.

Recommended replacement timing:

Immediately – in case of mechanical damage, visible cracks, or permanent conductive deposits.

During the next scheduled outage – if the electrode gap or insulation resistance is close to its limit values.

Proactively every few years – in environments with high overvoltage risk and heavy contamination, even if the spark gap appears to be in good condition.

9. The Importance of Operator Training – An Investment That Pays Off

Anyone who has been inside a prefabricated transformer substation during maintenance knows that the work of an operator or service technician is far from a desk job. Sometimes it means stepping into a cramped space in heat, frost, or after a storm, flashlight in hand, fully focused on details invisible to the untrained eye.

That’s why at Energeks we see operator training not as a “training expense,” but as a strategic investment in the safety and reliability of the installation.

Why knowledge is crucial

It helps distinguish normal spark gap wear marks from signs of failure.

It enables cleaning or replacement decisions without unnecessary downtime.

It supports accurate documentation of equipment condition.

The chain effect of good training

A trained maintenance team detects real threats faster, avoids costly “just in case” replacements, and takes care of equipment so that it stays fully operational for many years. It’s like a good car workshop – an experienced mechanic knows when a noise is part of normal operation and when it signals trouble, avoiding unnecessary repairs and costs.

Respect for people in the field

The best design and the most expensive transformer won’t stay safe if the operating team doesn’t have the skills, time, and tools to look after it. People are the first line of defense. The spark gap is the second.

Benefits for the investor

Training the team means lower failure and downtime risk, reduced long-term operating costs, and greater confidence that the infrastructure operates in compliance with standards and manufacturer guidelines.

Our approach

We combine theory with practice, show components in various conditions, explain phenomena in plain language, and answer every question – no matter how simple it may seem.

For us, education is not a lecture but a conversation, an exchange of experience, and the building of competencies that translate directly into real value in daily operations.

10. The future of surge protection – technology and people on the same team

Surge protection, with the spark gap as one of its elements, is a technology that combines engineering precision with human vigilance. It evolves alongside power networks, responding to the challenges of new renewable sources, operation in increasingly variable environments, and the need to ensure uninterrupted power supply in a world that doesn’t tolerate downtime.

In modern medium-voltage substations, spark gaps will increasingly operate in hybrid systems with MOV arresters, integrated into monitoring systems that record the number and parameters of operations, and housed in enclosures resistant to salt, moisture, and industrial dust.

If you are designing a new transformer substation, planning a network upgrade, or preparing for a compliance audit – we are here to help.

Visit our contact section if you need support in selecting, servicing, or documenting your surge protection systems.

We help you select, test, inspect, and prepare documentation so that your equipment operates without disruption – today, five years from now, and under conditions we cannot yet foresee.

Check our range of medium-voltage transformers – models compliant with PN-EN 60076, available off the shelf, with a full set of routine tests and optional special testing.

Join the Energeks community on LinkedIn. We share knowledge not to be in the spotlight, but to keep the grid running reliably.

Thank you for reading this text to the end.

We hope it has not only been a source of knowledge, but also an inspiration to ask more precise questions – because those questions are the fuel for every innovation.

SOURCES:

IEEE Xplore – “Spark Gap Devices for Surge Protection”

CIGRÉ Technical Brochure No. 549 – “Surge Arresters and Spark Gap Technologies”

IEC 60099-4: Surge arresters – Part 4: Metal-oxide surge arresters without gaps for a.c. systems –

Reviews

No reviews!