When a transformer starts leaking...

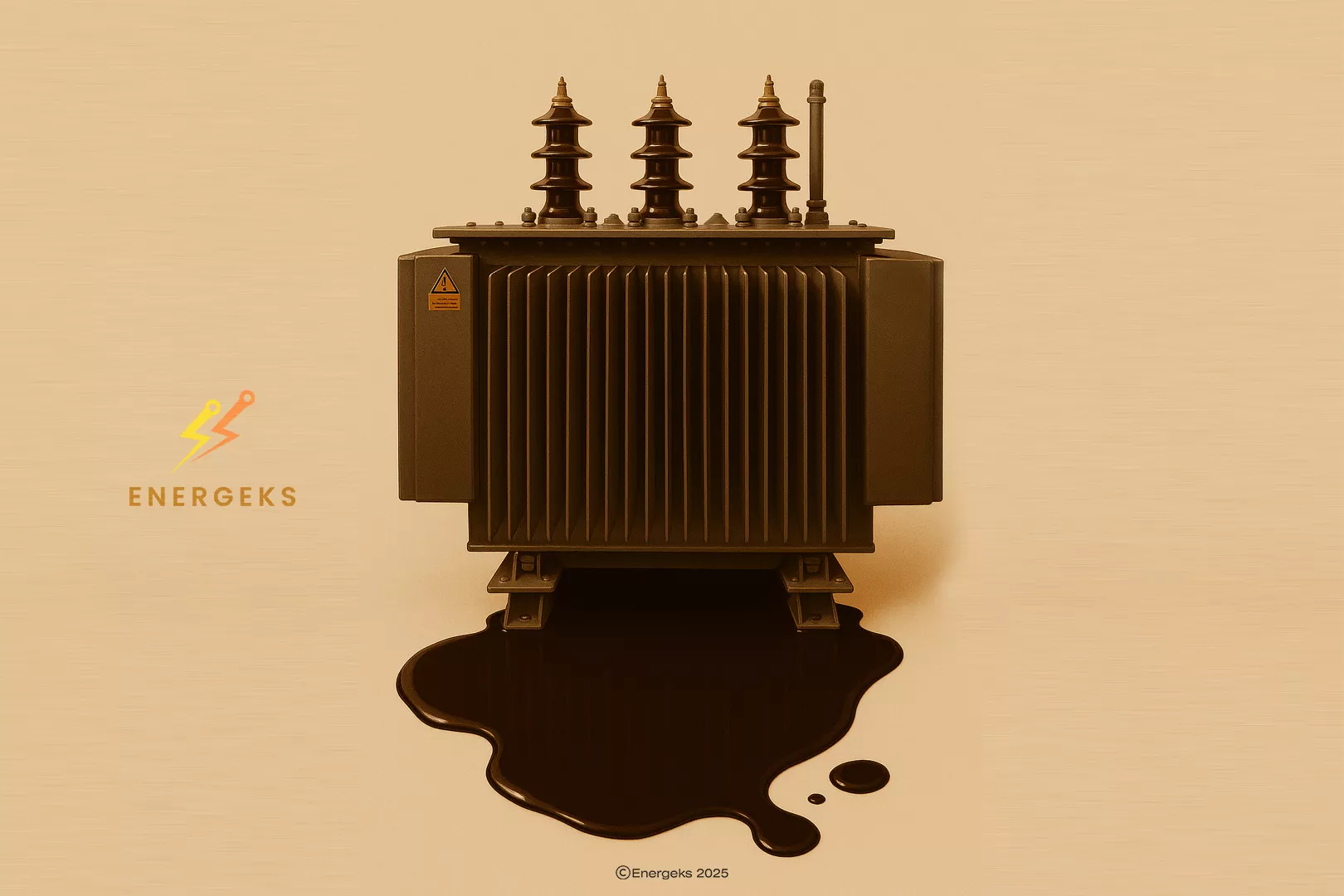

There it is. A stain. Seems small, but something about it feels off. Yesterday the floor was clean. Today it looks like the transformer... is sweating from nerves.

Don’t panic. Don’t wipe blindly. You’re not calling in the army yet. But if the very device meant to supply power starts losing something from within, that’s a sign. It’s time to stop and take a closer look.

This guide was made for moments like this.

With no pompous tone, just straight facts.

No fancy charts, but full respect for your work.

No fearmongering, but an honest view of what could happen.

Who is this guide for and what will you find inside?

For anyone who has ever seen a stain under a transformer and thought:

"I hope this isn’t something serious."

Here you’ll learn:

where leaks come from and what they might mean

when it’s still normal and when it becomes a risk

how to respond without making things worse

and finally, whether you can handle it yourself or need expert help

Reading time: 7 minutes

Why is oil leaking from the transformer?

An oil stain under a transformer is never just random.

If you notice a damp spot or drips under the unit, don’t count on it drying up on its own.

The oil inside a transformer plays a critical role. It’s responsible for cooling and insulation. When it starts escaping, it’s like a car engine losing oil. It might still run, but not for long.

What can cause a leak?

The most common sources of leaks include:

Gaskets and joints that wear out, harden or loosen over time, especially if the transformer has been in service for several years

The oil tank which might develop micro-cracks or show signs of corrosion, especially near the base

Cooling pipes and radiators where welds can become weak and allow oil to escape

Bushings that operate under electrical and thermal stress and may develop material fatigue

Excessive internal pressure due to rising temperatures, which can push oil through breathers or safety valves

In modern units, oil level and pressure sensors are often installed. But many older transformers lack them. And those are the ones most likely to surprise you with a stain.

Is it always serious?

Not every leak is a disaster in the making, but every leak must be taken seriously. Even a few unnoticed drops per day can, over time, reduce the oil level below its safe minimum.

And what happens then?

Cooling capacity drops, windings start to heat up

Insulation weakens, increasing the risk of flashover

Oil oxidizes when exposed to air and loses its dielectric properties

Deposits, acids, and other contaminants may begin to form

It’s like running an engine on dirty, degraded oil. It might work for a while, but everything starts clogging up.

Or is it just “sweat” from the breather?

Some operators ask: “Could this just be condensation or vapor from the breather?”

And yes, sometimes on hot days, light moisture may appear on the surface. But it should not leave a greasy mark or discoloration. If something is on the floor and leaves a stain after wiping, it’s most likely oil. And it means it’s time to act.

What’s the biggest threat here?

Long-term negligence. Because a leaking transformer won’t heal itself. With every passing day:

oil quality deteriorates

the risk of failure increases

repair costs grow

you’re exposed to environmental liabilities — in Poland, as per 2022 regulations, petroleum-based leaks must be removed and documented without delay

If it’s leaking, don’t panic, but don’t ignore it either.

This isn’t about cosmetics. It’s a sign of a process that can be stopped before it requires a full teardown and expensive regeneration.

The most common mistake? Waiting and watching.

Better to check once than pay ten times later.

Oil stain under the transformer – what to do?

You spotted a stain. You checked... it's not rainwater, not the technician’s coffee, not dirt from someone’s shoes.

It’s oil. Greasy, dark, maybe slightly oxidized.

What now?

The worst thing you can do is nothing.

An oil stain under a transformer is not something to leave for later. It’s an alarm signal that demands a specific response.

Step 1: Mark the spot and take photos

We're not playing detective here, but documentation is essential.

A stain may look small today, but in three days no one will remember if it was 10 or 50 centimeters wide.

Take a photo, measure the stain, mark the location – ideally with the date and time. This way:

you’ll see if the leak is growing

you’ll help the service team locate the issue faster

you’ll have evidence in case of an environmental incident report

Step 2: Check if the stain is “alive”

Meaning, is the leak still ongoing. You can check this by placing an absorbent mat (or even white technical paper) underneath and seeing after an hour if a new mark appears.

If yes, it's an active leak. If not, it might have been a one-time spill, but it still needs verification.

Step 3: Notify the responsible person

Sounds obvious? And yet, how many operators actually report these things? Too many assume “someone else will notice.”

Report the leak to the maintenance department, a technician, HSE inspector, or the facility manager.

According to regulations (e.g. the Polish Ministry of Climate and Environment’s 2022 ordinance), any petroleum-based oil stain is a potential environmental hazard.

Step 4: Conduct an oil quality analysis

The best way to assess a transformer’s condition after a leak is to take an oil sample and run lab tests. Key indicators include:

moisture content

acid number

breakdown voltage

color and smell

solid particles and sediment

It’s like a blood test – it helps detect issues before symptoms get serious. If the oil is contaminated, topping it up won't help. It must be filtered or replaced.

Step 5: Check oil level and pressure

Most modern transformers have oil level indicators (often with remote alarms), but if your model doesn’t, you'll need to check manually.

If the level drops below the minimum, overheating may occur.

Step 6: Remove the stain according to regulations

It’s not enough to mop it up and forget. Mineral oils are hazardous substances – they must be collected with absorbents, properly disposed of, and removal must be documented.

Ignoring this can result in fines or serious environmental consequences.

What do you gain by reacting quickly?

Lower costs – sometimes all it takes is a gasket replacement before things escalate

Less paperwork – better to file one report than face an inspection from the environmental authority

More peace of mind – knowing the situation is under control

The takeaway? A stain is not just dirt. It’s data. And data without action... is a loss.

Transformer is “sweating” – fault or normal?

You look at your transformer. You see droplets. Sometimes it’s just moisture. Sometimes something greasy. And then comes the classic question:

"Is it just sweating, or is it already leaking?"

So, where does normal end and trouble begin?

What does “sweating” mean anyway?

It’s a common expression among operators. It usually refers to:

moisture on the housing

condensation near breather valves

slight oiliness around connectors

In standard operating conditions, temperature differences inside and outside the transformer may cause water vapor to condense – especially in spring and autumn.

That doesn't necessarily mean something is broken.

What could be considered “normal”?

Water vapor – condensed moisture from the air, especially in cold mornings

Fogging of the breather – the breather system might “exhale” water vapor that condenses on cold surfaces

Greasy marks from dust and air particles – may look like oil but are really just residue

BUT – and this is important – none of these should leave greasy stains on the floor, soak into the concrete, or turn yellowish brown.

What is NOT normal?

A greasy mark that keeps growing

A mineral oil smell in the air

Oil streaks on the tank, radiator, or terminals

A falling oil level on the indicator

If the “sweat” leaves a mark after wiping with a cloth, it’s not moisture.

It’s oil. And that means you need to act.

How to tell sweat from a leak?

Here’s a quick five-step test:

Wipe the suspicious area with a clean, white cloth

Check for greasy residue

Smell it – does it have a “technical” oil scent?

Observe if moisture appears in the same spot every day

Look under the unit – if something is dripping, it’s not sweat, it’s a leak

Why take action even if it’s “just” sweat?

Because sweat may be the first sign of:

a damaged breather membrane

poor oil quality (prone to oxidation)

thermal overloading

ventilation issues in the tank

It’s like with people – we sweat before we get a fever.

Better to catch it early than battle a breakdown later.

What do we recommend?

Regular equipment inspections – at least once a week

Cleaning the casing – makes it easier to spot new leaks

Monitoring indicators – oil level, pressure, temperature

Checking gaskets and valves – especially after winter

Modern stations use sensors that trigger alarms when something changes.

But in older models, your best tools are: your eyes, your nose, and your experience.

A transformer may “sweat” slightly, but it should not be “weeping oil.”

If in doubt, check. The line between normal and risky is thin. And it usually starts with a single drop.

Oil is leaking from the transformer – repair or replace?

You have a transformer, it is leaking oil, and now comes the question worth several (or tens of) thousands:

can it be fixed, or do you need a new one?

Luckily, not every stain is a death sentence for the unit. But you do need to know when a gasket kit is enough, and when a tow truck and a full regeneration process are required..

What does the decision depend on?

the scale of the leak – is it a few drops a day, or a puddle after every shift?

the source of the leak – is it a cover gasket or a microcrack in the tank?

the transformer’s age – the older it is, the harder it is to repair in the field

the type of construction – some models (like hermetically sealed ones) require special procedures

the condition of the oil – sometimes the oil quality is no longer acceptable

downtime and cost – can you afford disassembly and transport?

What can be fixed on site?

Surprisingly, quite a lot:

replacing gaskets and sealing rings

tightening joints and bushings

cleaning the system and topping up the oil

removing contaminants and sludge (for example through filtration)

installing external tanks or emergency trays

Service teams often arrive with mobile equipment and within a few hours can restore tightness and even improve the oil quality, provided it has not degraded too far.

When is it no longer worth patching up?

if the leak comes from a corroded tank – the fix is temporary, the rust will return

if the transformer is over 30 years old and parts are no longer available

if the oil fails tests (e.g. breakdown voltage below 20 kV, acid number above 0.5 mg KOH/g)

if the unit has already experienced several leaks – that’s a sign of material fatigue

if the repair cost exceeds 40 to 50 percent of the value of a new unit

In such cases, it is wiser to invest in regeneration or replacement. Not only is it safer, but in the long run – simply cheaper.

On-site repair costs

The typical cost for on-site transformer repairs in 2025 ranges from €400 to €1,000 These services usually include replacing gaskets, tightening bushings and connections, topping up transformer oil, and performing basic sealing and leak prevention tasks. This option is cost-effective and suitable for small leaks or minor component degradation.

Transformer oil regeneration costs

Regenerating transformer oil—removing water, sludge, and acidic compounds—can cost between €7,400 and €11,100, depending on oil volume and contamination level (for example, 10,000 liters of oil). This procedure restores the oil’s dielectric and cooling capacity and is significantly less expensive than full oil replacement or full transformer overhaul.

New 400 kVA oil transformer cost

The purchase of a new 400 kVA oil-immersed transformer in 2025 costs anywhere to €27,000, depending on the manufacturer, technical specifications, insulation materials, and additional options such as monitoring sensors or custom design. Lower-cost models are typically manufactured in Asia, while high-performance variants with extended warranties are more expensive.

Practical insights

An on-site repair is often the most economical solution for minor leaks or sealing problems. If the oil is still in good condition and the structural integrity of the transformer remains intact, it is wise to act early and restore proper sealing.

Oil regeneration becomes the preferred option when the transformer is still functional, but the oil has degraded due to oxidation, contamination, or prolonged exposure to moisture. It can extend the operational life of the transformer by several years and prevent more serious failures.

If the transformer is over 30 years old, has had multiple past leaks, or if the cost of repair exceeds 40–50 percent of the price of a new unit, replacing it entirely may be the more sustainable long-term choice.

By responding early, you can minimize downtime, reduce repair costs, and avoid environmental penalties associated with oil spills and non-compliance with national environmental regulations.

What about time?

Time is often the deciding factor.

On-site repair – 1 to 2 days

Oil regeneration – up to 2 weeks

Ordering a new unit – anywhere from 3 weeks to 3 months

That’s why it’s worth making a decision early, before a small leak escalates into a failure that shuts down the entire production line.

Repair it yourself or call the service team?

If you’re a trained operator, with oil testing equipment, spare parts and clear safety procedures, you can begin with some basic steps:

Identify the leak location

Check oil levels

Document the event

But any attempt to intervene without certification may not only be dangerous, it could also be illegal, especially when medium-voltage insulation systems are involved.

That’s why we recommend: if in doubt – call the service team.

It’s better to spend €100 on a diagnosis than €10,000 on a failure.

If you're facing a decision between repairing or replacing an aging unit, check out our in-depth article:

Refurbish or replace? Last chance for your transformer!

– a must-read for anyone managing transformers over 30 years old.

Trust the stain - it knows what it’s doing

A transformer has no mouth, but it knows how to speak.

Through a greasy stain. A sharp smell. A strange humming.

Not because it wants to cause trouble, but because it gives you a chance to act before things spiral out of control.

You don’t need to know everything right away.

It’s enough to notice, name it, and check it.

And if you’d rather do it with someone who truly knows their stuff, we’re right here on the other end of the wire.

See what we’ve got ready, what we can deliver fast, and how we can help get your station back in shape:

→ Solutions for transformer stations

→ Transformers in stock – browse available models

→ Full range of MarkoEco2 oil-immersed transformers

And if you’d like to join a community that shares good energy – in every sense of the word – come visit us on LinkedIn.

You’ll find knowledge, support, and people who genuinely get it.

Thanks for being here with us.

When you’re ready, we’re back in the game!

Sources:

IEEE: Suppression of Transformer Oil Surges Caused by External Short-Circuit Faults Using an SFCL

Reviews

No reviews!