K-Factor is not just another number on the nameplate.

Imagine your switchgear is the heart of your facility, and the transformers powering it are its lungs. Now picture that with every new drive, inverter, LED power supply, or server... you are polluting that air.

Harmonic currents are the invisible smog in your system, and the transformer’s K-Factor is the oxygen mask that allows the system to function despite the pollution. The K-Factor relates to the operating conditions of a transformer and can be defined as a class of resistance to non-linear loads.

Sounds complicated?

We’ll explain everything in a moment! We provide transformers designed to withstand extreme harmonic saturation environments. We understand how costly improper transformer selection can be, which is why we share knowledge that can save your installation from unnecessary stress and your budget from unexpected costs.

If your devices operate in sync with harmonics, this article will help you understand how to choose a transformer that won’t burn out at startup.

In today’s publication, we will cover:

What is the K-Factor, and how is it determined?

Why are harmonic currents so dangerous?

Third-order harmonics (triplen harmonics) – the enemy of three-phase installations

What is a K-Rated transformer, and how is it built?

How to select the right K-Factor for your load type?

When is a K-Rated transformer not enough, and should you consider an HMT?

Standards and testing: UL, IEEE, CSA – what you need to know

Reading time: 14 minutes. The time spent reading this is a step toward a more reliable, efficient, and safer infrastructure. Thank you for being here with us – we share our expertise to help your systems perform at their best!

What is the K-Factor, and how is it determined?

The K-Factor is a key indicator of a transformer’s resistance to harmonic currents generated by non-linear loads. It determines the transformer’s ability to operate under conditions of a highly distorted current sine wave without overheating or accelerated wear. In short: the higher the K-Factor, the better the transformer can handle harmonics.

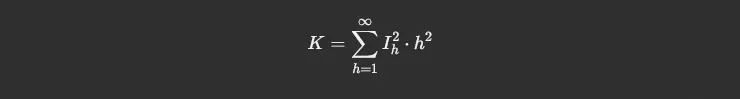

But where does this number come from? The K-Factor is not an arbitrarily assigned parameter—its value results from precise calculations based on the level of harmonics present in a given power system. It is determined using the following formula:

Where:

h – order of the harmonic (e.g., 3rd, 5th, 7th, etc.).

Ih – harmonic current in per unit (pu), meaning as a fraction of the rated current.

Each harmonic affects the total transformer load, particularly its operating temperature. Higher harmonics generate greater losses, which can lead to excessive heating of the windings and core. This is why standards such as IEEE C57.110 and UL 1561 define how the K-Factor should be tested and classified.

How does this work in practice?

For standard K-rated transformers, the K-Factor values fall into specific ranges:

K1 – General-purpose transformer, no need for harmonic resistance.

K4 – For applications with moderate levels of harmonics, e.g., AC drives.

K13 – For installations where non-linear loads dominate, e.g., LED lighting systems, offices, schools, hospitals.

K20 – Designed for data centers, laboratories, and server rooms, where strong harmonics are generated by IT equipment.

K30-K50 – For extreme environments, such as heavy industry and facilities with high harmonic content.

This classification allows power system engineers to precisely select the appropriate transformer based on operating conditions. Using too low a K-Factor in a high-harmonic environment can result in overheating, neutral wire overload, and reduced transformer lifespan.

The K-Factor is not a cure-all for harmonic problems, but when properly selected, it extends the transformer’s life and enhances efficiency in dynamic and harmonic-rich power networks.

Harmonics – what is really eating your transformer?

Harmonic currents are an invisible but potentially dangerous phenomenon for electrical installations. They arise as a byproduct of modern electronic devices—inverters, motor drives, LED lighting, and servers. Unlike standard sinusoidal currents at 50 Hz (Europe) or 60 Hz (North America), harmonics are multiples of the fundamental frequency: 150 Hz, 300 Hz, 450 Hz, and beyond.

Why is this a problem?

Because harmonic currents are not “pure” currents, but distortions that introduce additional loads on the installation, leading to several negative effects:

Excessive winding heating – Harmonics increase thermal losses, accelerating insulation aging and shortening transformer life.

Mechanical core vibrations – Variable electromagnetic forces caused by harmonics generate vibrations, increasing mechanical stress and potential damage.

Elevated neutral wire temperatures – Especially in third-order harmonics (triplen harmonics), which accumulate on the neutral conductor instead of canceling out.

Increased losses in the core and windings – Harmonics introduce additional eddy current and hysteresis losses, reducing transformer efficiency.

It’s like running an engine on contaminated fuel—it still works, but under greater strain and wears out faster.

Why are harmonic currents so dangerous?

Harmonics are not unusual, but their accumulation and long-term effects pose serious problems. In traditional installations where linear loads dominate (e.g., conventional electric motors, incandescent bulbs), harmonics are nearly nonexistent. However, in modern industrial plants, data centers, or hospitals, where inverters, UPS systems, and power converters are widespread, harmonic levels can reach 30-50% of the total load.

The consequences?

1️⃣ Excessive transformer heating – Standard transformers are designed for sinusoidal currents. When connected to harmonic-generating devices, effective power loss in the windings increases. If the transformer is not designed for this (does not have the appropriate K-Factor), its winding insulation deteriorates, leading to premature failure.

2️⃣ Neutral wire overheating – In three-phase systems, third-order harmonics and their multiples (triplen harmonics) have a unique property: instead of canceling out across phases, they accumulate in the neutral conductor. This means that if each phase carries 10 A of harmonic current, the neutral wire can carry up to 30 A. This overheats the conductor, raising the risk of insulation failure.

3️⃣ Electronic equipment interference – High harmonic content in the power network can cause unstable operation of sensitive electronics. This affects not only the transformer but also the devices it powers—from PLC controllers to medical and IT systems.

4️⃣ Lower efficiency and higher operating costs – Additional energy losses caused by harmonics lead to higher electricity bills and the need to oversize installations. Every percentage of harmonics represents extra energy wasted as heat, instead of being used for productive work.

That’s why general-purpose transformers are unsuitable for harmonic-rich environments. They must be replaced with K-rated units, specifically designed to withstand these distortions without overheating or failure.

Harmonics are the silent destroyer of power infrastructure. In modern installations, their levels are often so high that ignoring the problem results in serious consequences—overheating, performance drops, and increased maintenance costs.

Selecting the right K-Factor transformer is not optional—it’s a necessity.

Third-Order Harmonics – The Neutral Conductor as a Heating Element?

In a classic, ideal three-phase system, the currents in the phase conductors are shifted by 120 degrees relative to each other. This means that under normal conditions, if the load is symmetrical and free of harmonics, the sum of the currents in the neutral conductor should be close to zero.

The problem begins when third-order harmonics and their multiples (triplen harmonics – 3rd, 9th, 15th, etc.) appear in the system. Unlike higher-order odd harmonics (e.g., 5th, 7th), which mostly cancel out in a three-phase system, triplen harmonics add up in the neutral conductor instead of canceling out.

Why Are Third-Order Harmonics the Enemy of a Three-Phase Installation?

1️⃣ The Neutral Conductor Operates Under Unexpected Load

In a system without harmonics, the neutral conductor carries only small differences between the phase currents. However, when third-order harmonics are present, the current in the neutral conductor can be several times higher than in any individual phase.

Example:

If each phase contains 1 A of third-order harmonic current, the neutral conductor will carry not 1 A, not 2 A, but 3 A! And if more harmonics are present? The neutral wire can be overloaded beyond the total phase current, leading to overheating and potential insulation failure.

2️⃣ Overheating of the Neutral Conductor and Connections

Elevated neutral conductor temperature is one of the most dangerous effects of third-order harmonics. In standard installations, the neutral is assumed to carry a relatively low load. No one designs installations expecting the neutral conductor to carry such high currents!

If the neutral conductor is not designed to handle harmonics, it may result in:

Insulation degradation due to high temperature.

Damage to connection points and terminals (especially with repeated overheating).

Risk of fire in extreme cases.

3️⃣ Malfunction of Circuit Breakers and Protection Devices

A high level of harmonics in the neutral conductor can disrupt the operation of protection devices such as residual current devices (RCDs) and overcurrent protection. This may lead to:

False tripping of breakers (causing unnecessary power outages).

Ineffective protection against actual overloads, when the protection device fails to detect a real hazard.

4️⃣ Additional Power Losses and Reduced System Efficiency

Third-order harmonics not only overload neutral conductors but also increase total losses in the system. Additional energy is not used for useful work—instead, it turns into heat, leading to:

Higher electricity costs (since energy is wasted as heat rather than used by devices).

Increased transformer heating, which may shorten its lifespan.

Third-order harmonics are one of the most deceptive phenomena in three-phase power systems. Counterintuitively, they do not cause significant issues in phase conductors but instead concentrate their destructive effects on the neutral conductor, making it the weakest link in the installation.

Ignoring this problem can lead to:

❌ Overloaded and overheated neutral conductors

❌ Increased power losses and operating costs

❌ Malfunctioning electrical protection devices

❌ Risk of failure and fire hazards

How Does a K-Rated Transformer Solve This Problem?

A regular transformer is not designed to handle high harmonic currents. Therefore, K-rated transformers, such as K13, K20, or K30, have several key features that enable them to operate in high-harmonic environments, particularly third-order harmonics:

✔ Oversized neutral conductor bar – designed for currents equal to 200% of the full load current.

✔ Special winding and conductor geometry – to reduce harmonic-related losses.

✔ High-quality insulation materials – resistant to higher temperatures generated by harmonics.

✔ Cooling adapted to additional power losses – to prevent transformer overheating due to harmonics.

Example:

A K13 transformer rated at 75 kVA with a 208V secondary voltage must have a neutral bus designed for 720 A—twice the full load current!

By comparison, a standard transformer of the same power rating would have a neutral bar rated for only 360 A, which would be insufficient in the presence of third-order harmonics.

What is a K-Rated Transformer and How is it Built?

A K-Rated transformer is a specially designed unit built to operate in environments where current harmonics cause additional heating, overloads, and power losses. Unlike standard transformers, K-Rated models are engineered to handle nonlinear loads such as AC drives, server rooms, LED lighting, or industrial inverters without the risk of overheating or premature insulation degradation.

In practical terms, a K-Rated transformer must withstand extreme operating conditions while ensuring voltage stability, reducing power losses, and efficiently dissipating excess heat. This is why its construction differs significantly from that of traditional transformers.

What Does a K-Rated Transformer Look Like Inside?

If a standard transformer can be compared to a passenger car that performs well on smooth roads, then a K-Rated transformer is an off-road vehicle designed for the most challenging conditions. It is built to survive in environments full of harmonic disturbances without losing efficiency.

1️⃣ Reinforced Neutral Busbar and High-Capacity Connections

One of the key structural elements of K-Rated transformers is a neutral busbar with increased current capacity. Standard transformers are designed for a neutral path capable of carrying around 100% of the rated current. However, in K-Rated transformers—especially K13 and higher—the neutral busbar and its connections must handle 200% of full-load current.

This is crucial because high levels of harmonics, particularly third-order harmonics (triplen harmonics), accumulate in the neutral conductor. A poorly designed neutral path leads to excessive heating, which, in extreme cases, can cause insulation breakdown and system failure.

2️⃣ Special Winding Geometry – Reducing Harmonic Losses

Current harmonics generate additional power losses in the transformer, primarily in the form of heat dissipation in windings and the core. To minimize these losses, K-Rated transformers use optimized winding geometry, often employing:

Multiple parallel conductor windings, which reduce the impact of higher-order harmonics.

Special wire arrangements that decrease skin effect and eddy current losses.

Increased coil turns per voltage unit, which improves resistance to harmonic disturbances.

Thanks to these design enhancements, the transformer can operate under high harmonic saturation without exceeding permissible operating temperatures.

3️⃣ High-Quality Electrical Steel, Copper, or Aluminum

To reduce core losses, a K-Rated transformer is constructed using premium-grade materials. The cores are made from high-purity electrical steel, minimizing hysteresis losses and reducing heating caused by harmonics.

The windings can be made from either copper or aluminum, depending on application requirements. Copper provides lower resistive losses, but properly designed aluminum windings can also deliver high efficiency.

4️⃣ Larger Air Gaps Between Windings for Better Cooling

Operating in nonlinear load environments generates more heat. To counteract this, K-Rated transformers are designed to enhance airflow around the windings. Larger gaps between windings and additional cooling channels allow for better heat dissipation, increasing insulation lifespan and reducing the risk of overheating.

In some models, ventilated enclosures or forced air cooling (for larger units) further enhance resistance to excessive heating.

Standards and Testing – How is a K-Rated Transformer Evaluated?

Every K-Rated transformer undergoes strict industry standards and testing to ensure resistance to harmonics and long-term reliability in demanding environments. The most important standards include:

UL 1561 – The industry benchmark for dry-type transformers, defining harmonic resistance, thermal endurance, and operational safety.

CSA C22.2 No. 47-13 & C9-17 – Canadian standards that include low and medium voltage transformer testing, considering harmonic current impacts on durability.

IEEE C57.110 – Guidelines for engineers on designing and testing transformers for environments with nonlinear loads.

The testing process for K-Rated transformers includes:

Thermal tests – Assessing the transformer's ability to operate at high temperatures and under significant harmonic losses.

Voltage tests – Simulating real-world operating conditions to verify that insulation and windings can withstand overloads.

Dynamic load tests – Evaluating how the transformer responds to rapid load changes and sudden harmonic spikes.

Why is a K-Rated Transformer Essential for Modern Power Systems?

A K-Rated transformer is a critical component in electrical infrastructure where significant harmonics are generated by modern devices. Its design is optimized to withstand heating effects, neutral conductor overloads, and increased winding losses caused by harmonics.

Key construction features include:

✔ Neutral busbar rated for 200% of full-load current.

✔ Special winding configurations to minimize harmonic losses.

✔ High-quality core and winding materials.

✔ Enhanced cooling to prevent overheating.

Without K-Rated transformers, installations with high harmonic content are more prone to failures, energy losses, and reduced equipment lifespan. Their selection is not just about safety—it’s about cost optimization and ensuring the long-term efficiency of the entire electrical system.

How to Select the Right K-Factor for Your Load?

Selecting the correct K-Factor for a transformer is not arbitrary – it is a crucial aspect of power system design, especially in environments with high harmonic content. A transformer that is not properly matched to its load can overheat, lose efficiency, and fail prematurely, leading to increased operational and maintenance costs.

To properly determine the K-Factor, two main factors must be analyzed:

1️⃣ Load Characteristics – Do the devices connected to the transformer generate significant harmonic currents?

2️⃣ Level of Harmonic Saturation in the Network – What percentage of the total power consumed by loads contains harmonic distortion?

Linear vs. Nonlinear Loads

Not all equipment contributes to harmonic distortion in a power system. Linear loads are those that draw current in a clean, sinusoidal waveform – they do not introduce harmonic distortion and can be powered by standard transformers (K1-rated).

Examples include:

Traditional electric motors without electronic speed control.

Incandescent lighting and conventional HVAC systems.

Household appliances and basic industrial equipment.

On the other hand, nonlinear loads are devices that interrupt sinusoidal current flow, generating additional harmonic components. The higher their proportion in the system, the more the voltage waveform is distorted, requiring transformers with higher harmonic handling capabilities.

This category includes:

Variable Frequency Drives (VFDs, Inverters) – Generate 5th, 7th, 11th harmonics and beyond.

Switch Mode Power Supplies (SMPS) – Found in computers, servers, and medical equipment.

LED and fluorescent lighting systems – Produce 3rd and 9th order harmonics.

UPS systems and power converters – Cause significant harmonic distortion, necessitating K-Rated transformers.

When to Choose a Higher K-Factor?

If your electrical network consists mostly of nonlinear loads, the K-Factor must be carefully matched.

✔ Moderate Harmonic Levels (K4–K9) – If up to 50% of the load consists of nonlinear devices, such as AC drives and heating systems with electronic power control, a transformer with a K-Factor of K4 to K9 is recommended. This ensures proper heat dissipation in the windings and core, extending the lifespan of the transformer.

✔ High Harmonic Saturation (K13–K20) – If the system consists of 50–100% nonlinear loads, such as server power supplies, commercial building lighting systems, or IT infrastructure, choosing a K13 or K20 transformer is a necessity. In these cases, harmonics can overload the neutral conductor, and a K-Rated transformer with a neutral bus designed for 200% of rated current prevents overheating and failures.

✔ Extreme Operating Conditions (K30–K50) – If the load consists almost entirely of harmonic-generating equipment, such as heavy industrial systems, data centers running at full capacity 24/7, or research laboratories, a K30 or higher transformer is required to ensure reliable operation in extreme environments.

Why is Selecting the Right K-Factor So Important?

1️⃣ Prolonged Transformer Life – An improperly rated transformer may operate at temperatures exceeding acceptable limits, causing gradual insulation degradation and the need for costly replacements.

2️⃣ System Safety and Stability – High harmonic content can interfere with electrical protection devices, leading to unexpected system shutdowns. A K-Rated transformer reduces these risks, improving power reliability.

3️⃣ Optimized Operating Costs – Heat losses caused by harmonics increase energy consumption, directly impacting electricity costs. A properly selected transformer minimizes unnecessary losses and enhances system efficiency.

K-Factor Selection Guidelines

For predominantly linear loads (traditional motors, lighting without electronic drivers) → Standard K1 transformer is sufficient.

For systems with moderate harmonic content (inverters, AC drives) → K4–K9 transformers are recommended.

For environments with high harmonic saturation (server rooms, hospitals, offices with high electronic load) → K13–K20 transformers are required.

For the most demanding industrial installations (factories, facilities with extensive use of VFDs) → K30–K50 transformers are necessary.

Choosing the right K-Rated transformer is not just a technical decision – it directly impacts system reliability, energy efficiency, and long-term cost savings.

When a K-Rated Transformer Is Not Enough?

1️⃣ When harmonic levels exceed 30-40% of the total load current

A K-Rated transformer is designed to tolerate the heating effects caused by harmonics, but it does not eliminate their source. If the harmonic levels exceed 40% of the total current, even a K50 transformer will only withstand this load rather than reduce it.

2️⃣ When harmonics affect the operation of electronic equipment

Excessive harmonic distortion can cause voltage instability, leading to failures in PLC control systems, synchronization issues in devices, and random resets of sensitive electronics.

Examples of affected environments:

Precision industrial automation systems – Harmonic distortion can cause control errors and improper machine operation.

Laboratory and medical equipment – Harmonics can interfere with the sensitivity of measurement instruments.

Data centers and server rooms – Excess harmonics may cause voltage instability and increase UPS failure rates.

3️⃣ When neutral conductor overload becomes critical

As previously mentioned, third-order harmonics (triplen harmonics) accumulate in the neutral conductor rather than canceling out. A high concentration of these harmonics leads to excessive heating of the neutral wire and connections, which in extreme cases may result in system failure.

If your system experiences neutral overheating and a K-Rated transformer, despite its reinforced neutral bus, does not solve the issue, an HMT transformer will be a better solution.

4️⃣ When energy losses are too high

Harmonics not only overload conductors and transformers but also increase total system power losses. In large industrial plants or IT infrastructures, additional losses caused by harmonics can result in higher energy bills and increased cooling costs.

In such cases, a harmonic mitigating transformer (HMT) can significantly reduce harmonic levels, improving the overall efficiency of the system.

How Does an HMT Transformer Work?

A K-Rated transformer is like a protective shield – it allows the system to survive in difficult conditions but does not eliminate harmonics. An HMT transformer functions like an active filter – it not only protects but also reduces harmonic distortion, improving power quality throughout the system.

An HMT transformer achieves this through:

Optimized winding geometry that neutralizes specific harmonic orders.

Additional compensating circuits that actively reduce system disturbances.

Phase shifting techniques in windings to mitigate harmonic impact on voltage and current.

As a result, instead of merely enduring harmonics, an HMT actively eliminates them at the source, before they can cause disruptions.

When to Choose an HMT Over a K-Rated Transformer?

✔ If the system has extremely high harmonic levels (above 40% of the load).

✔ When harmonics are causing failures in control systems, servers, laboratory, or medical equipment.

✔ If the neutral conductor is overloaded and simply increasing its cross-section does not resolve the issue.

✔ When harmonic-related energy losses are significant enough that investing in a harmonic-reducing transformer is cost-effective.

If a K-Rated transformer is the first line of defense against harmonics, an HMT transformer is a comprehensive solution for eliminating the problem at its source.

In environments with extreme harmonic saturation, critical applications, and industries where the highest power quality is essential, a K-Factor transformer alone is not enough – active mitigation is necessary.

This is no longer just a matter of resilience, but of efficiency, cost savings, and system reliability.

Standards and Testing: UL, IEEE, CSA – What You Need to Know

It is not enough for a K-Rated transformer to simply be declared resistant to harmonics – it must undergo rigorous testing and verification according to strict industry standards. These standards define temperature limits, allowable power losses, and K-Factor calculation methods, as well as minimum construction requirements that manufacturers must meet.

1. UL 1561 – American Quality Standard for Dry-Type Transformers

One of the most critical documents in the industry, UL 1561, covers requirements for dry-type power transformers and general-purpose transformers, including those designed to operate under non-linear loads. This standard defines:

Maximum permissible transformer operating temperatures (taking into account heating caused by harmonics).

Minimum thermal resistance of winding insulation – crucial for K-Rated transformers that must withstand additional heating.

Neutral conductor design requirements – for K-Rated transformers, this means neutral connections capable of carrying 200% of the rated current.

Compliance with UL 1561 ensures that the transformer not only survives in high-harmonic environments but also meets long-term safety requirements.

2. IEEE C57.110 – Essential Guidelines for Transformers in Harmonic-Rich Environments

The IEEE C57.110 standard (Recommended Practice for Establishing Transformer Capability When Supplying Non-Sinusoidal Load Currents) is one of the most detailed documents describing the effects of non-linear loads on transformers. It provides:

Methods for determining the K-Factor – how to accurately calculate a transformer's resistance to harmonics.

Derating principles (reducing transformer capacity) – how to adjust the transformer's nominal power rating when it operates under high harmonic distortion.

The impact of individual harmonic orders on thermal losses – crucial for selecting the appropriate core and winding materials.

Compliance with IEEE C57.110 ensures that the transformer is designed not just to withstand harmonics but to operate efficiently under challenging conditions.

3. CSA C22.2 No. 47 & C9 – Canadian Testing Standards

The CSA C22.2 No. 47-13 and CSA C9-17 standards apply to both dry-type and oil-filled transformers. These regulations focus on:

Durability testing – ensuring transformers can withstand long-term stress.

Voltage tests – verifying insulation integrity under real operating conditions.

Thermal endurance testing – ensuring materials can handle the heat generated by harmonic-rich loads.

Importantly, Canadian CSA standards are often aligned with UL (U.S.) and IEC (international) standards, meaning a transformer that meets CSA requirements is ready for use in any power system, from heavy industry to commercial grids and IT infrastructure.

This Is Just the Beginning…

If you question whether your system is operating at maximum efficiency, it’s worth analyzing the issue at its source. At Energeks, we support our partners daily in optimizing energy consumption, simplifying power systems, and eliminating unnecessary costs. This allows us to not only deliver proven solutions but also share knowledge and real-world expertise.

Need a transformer available immediately?

We offer a wide range of units tailored to modern installations with high harmonic content. Check out our full product lineup and choose a transformer that ensures long-term, trouble-free operation for your infrastructure.

Join the Energeks community on LinkedIn!

We regularly share not only product updates but also practical insights, market analyses, and real-world case studies. If you’re modernizing your power network or looking to exchange knowledge with industry experts – let’s start a conversation!

Energeks is not just about products – it’s about the people shaping the future of energy. Contact us and find out how we can help support your project!

References:

Reviews

No reviews!