Update: January 2026

Have you ever wondered what a transformer really is and why some are oil-filled while others are dry-type?

A transformer is an electrical device used to change the voltage level in power systems, enabling the safe transmission and distribution of electrical energy.

The two most commonly used types are oil-filled transformers and dry-type, resin-insulated transformers.

The fundamental difference between an oil-filled and a dry-type transformer lies in the cooling and insulation method. A dry-type transformer is air-cooled and contains no insulating liquid, whereas an oil-filled transformer uses transformer oil, which simultaneously cools and insulates the windings.

The choice between an oil-filled and a dry-type transformer depends on power rating, installation location, and safety requirements.

It is precisely this construction detail that influences where a given transformer can operate, what power levels it can handle, and how it will be maintained.

In the following part of the article, we show how these differences translate into real-world applications.

What is the difference between a dry-type and an oil-filled transformer?

The main difference between a dry-type and an oil-filled transformer stems from their internal construction and heat dissipation method. Dry-type transformers, as the name implies, do not use liquid substances for cooling. The windings are not immersed in any fluid, and the heat generated during operation is dissipated into the surrounding environment through natural or forced air circulation around the windings.

This type of construction means dry-type transformers are often used in locations where fire safety is of critical importance. This applies primarily to public buildings and indoor industrial installations where the presence of oil would be undesirable.

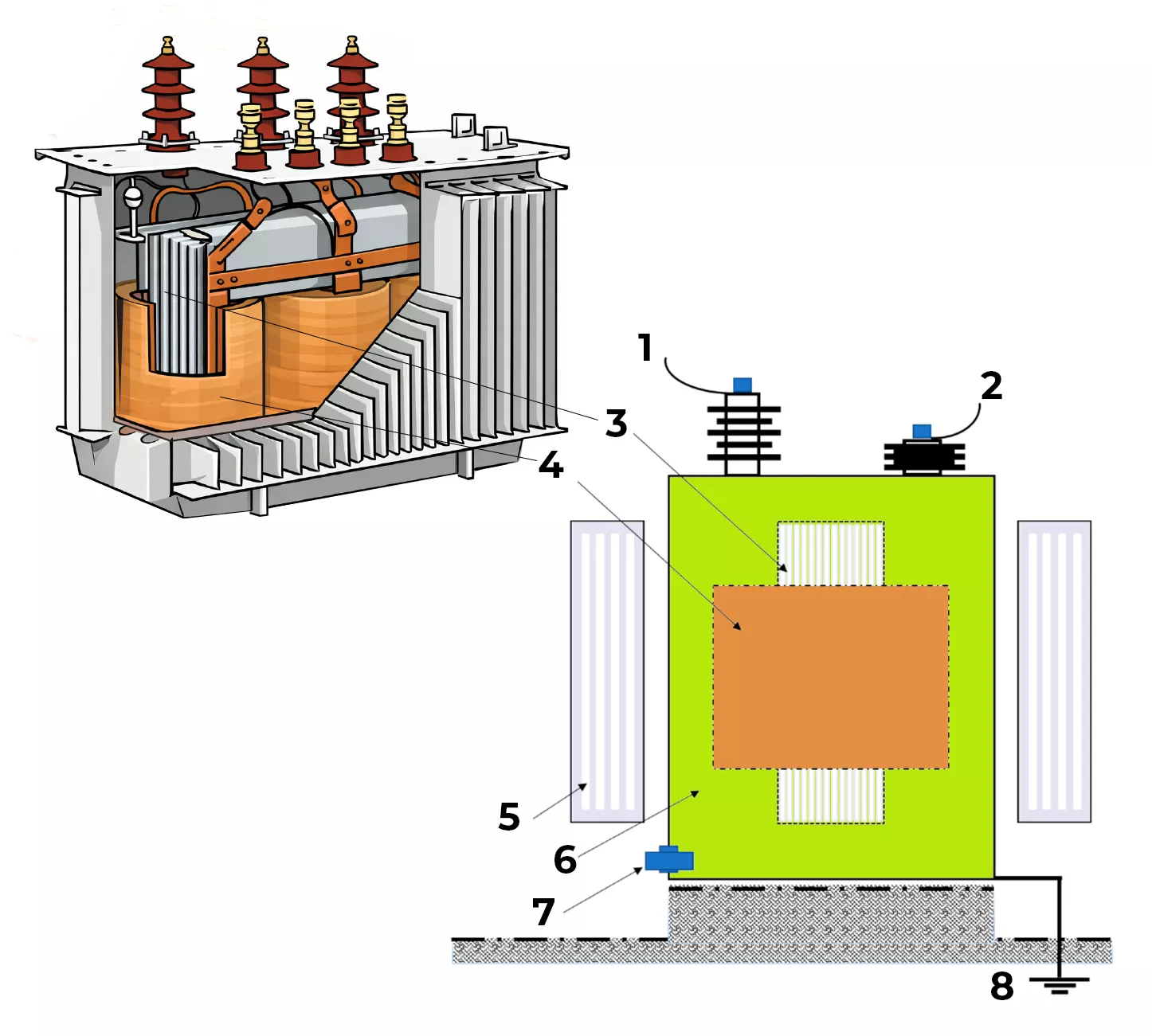

Oil-filled transformers operate on a different principle. Both the windings and the core are immersed in transformer oil, which circulates inside the tank, effectively absorbing heat and transferring it to the cooling system. The oil serves a dual function: it cools the transformer's active components and provides them with electrical insulation.

This allows oil-filled transformers to handle high loads and long-term operation at high power much more effectively, which is why they dominate industrial and distribution power systems. In practice, this means dry-type transformers are more often chosen for indoor installations, while oil-filled transformers are used where high power and long-term operational stability are fundamental.

Illustration 1: A schematic cross-section of an oil-filled transformer showing the windings, magnetic core, and oil insulation used in medium-voltage transformers.

The diagram indicates: 1). High-voltage side, 2). Low- and medium-voltage side, 3). Transformer core, 4). Windings, 5). Radiator, 6). Mineral oil serving insulating and cooling functions, 7). Grounding ensuring operational safety.

CC: Energeks / researchgate.net

What is a dry-type / cast-resin transformer?

In industry practice, the terms "dry-type transformer" and "cast-resin transformer" are used interchangeably and refer to the same manufacturing technology. This is not a linguistic simplification, but a precise description of the transformer's construction and the insulating material used.

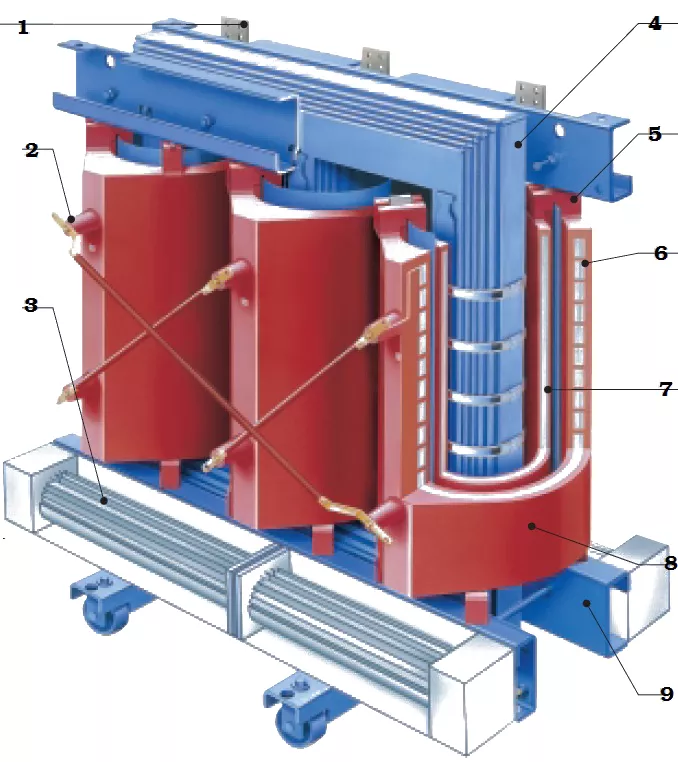

A dry-type transformer is a transformer that does not use a liquid insulating or cooling medium, such as oil. Its windings are cast in epoxy resin, hence the term "cast-resin." The resin creates a compact and durable structure that electrically insulates the conductors, protects them from moisture and contamination, and stabilizes the entire construction mechanically.

The term "dry" emphasizes the absence of liquid in the transformer, while the term "cast-resin" specifies the method of implementing the insulation. From a technical point of view, both concepts describe the same solution, and their parallel use stems from different reference points: construction and material.

Thanks to the use of epoxy resin, a dry-type transformer:

• presents no risk of leakage,

• is characterized by a low fire hazard,

• is resistant to moisture and dust,

• can be installed directly inside buildings.

This is precisely why dry-type transformers are increasingly being deployed where there is no room for chance or improvisation: in hospitals, data centers, public utility buildings, and modern industrial installations. There, safety and predictable operation are not an add-on, but a condition of entry.

If you want to see how these principles look in real operational scenarios, check out the article:

Dry-type transformer. 5 reasons why it wins in harsh conditions

where you will learn about specific applications, limits of capability, and situations where this technology truly makes sense.

Illustration 2: Cross-section of a dry-type transformer's windings cast in epoxy resin.

The illustration shows a cross-section of a dry-type transformer with windings cast in epoxy resin, featuring a visible magnetic core, an air-cooling system, and structural elements responsible for mechanical stability and safe operation. The diagram is labeled: 1). low-voltage terminals, 2). high-voltage terminals, 3). transverse fans, 4). three-phase core, 5). flexible spacing elements, 6). high-voltage winding, 7). low-voltage winding, 8). insulation in the form of an epoxy resin and quartz powder compound, 9). pressing frame and transport trolley.

CC: efxkits.com

What is an oil-immersed transformer used for?

The oil-immersed transformer is the standard in utility and industrial power. It is found in medium and high-voltage substations, industrial plants, photovoltaic farms, power plants, and distribution infrastructure.

Its greatest advantage is its ability to transfer large amounts of power while maintaining stable operating parameters. Transformer oil effectively absorbs heat from the windings and core, allowing for prolonged operation under high load without the risk of overheating.

In practice, oil-immersed transformers are chosen where:

• high rated power is required,

• the device operates continuously,

• the installation is located outdoors,

• high overload resistance is important.

The oil-immersed transformer is designed for long-term, stable operation in varying environmental conditions. The high thermal capacity of the oil allows for transferring large amounts of power with relatively compact dimensions, which is particularly important in outdoor installations where operating conditions are far from laboratory-perfect.

Photo: A pole-mounted substation with an oil-immersed transformer installed on a utility pole, used in medium-voltage distribution networks. This type of solution is used in distribution networks where the device operates in variable environmental conditions.

Photo CC: Energeks 2025

A good example is photovoltaic installations, where the transformer operates under conditions of variable load, large temperature fluctuations, and cyclic overloads resulting from the nature of power generation. In such applications, not only the rated parameters matter, but also the cooling method, resistance to prolonged continuous operation, and the predictability of energy losses over time.

For small and medium-sized PV farms, the choice of transformer often directly impacts the profitability of the entire project, not just its technical parameters. Differences in efficiency, ability to operate under partial loads, and maintenance requirements translate directly into operational costs and installation stability.

To learn more about how different types of transformers perform in installations of 50 kW, 100 kW, and 150 kW, and why in many cases the oil-immersed transformer remains the most versatile solution, check out the article:

What transformer for a small photovoltaic farm of 50 kW, 100 kW, or 150 kW? We answer

Oil-immersed or dry-type transformer? How to make the right choice

The choice between an oil-immersed and a dry-type transformer should not be an automatic decision or based solely on a single parameter. In practice, it is always an analysis of the device's operating conditions, required power, installation location, and expectations regarding safety and subsequent operation.

The modern oil-immersed transformer is no longer a device based on decade-old solutions. The development of insulating materials, cooling technologies, and core design means that today's constructions meet much higher efficiency and environmental requirements than before.

It will prove itself where high power, overload resistance, and stable operation in outdoor conditions are fundamental. This type of construction dominates in industrial and distribution power, where the device operates continuously and must maintain reliability for many years.

An example of this approach is the MarkoEco2 oil-immersed transformer, designed with long-term stable operation and compliance with current normative requirements in mind, including CE documentation and energy loss levels compliant with Tier 2.

In practice, this type of construction meets the needs of installations where the repeatability of parameters, resistance to variable load conditions, and predictability of operating costs over the entire device life cycle are just as important as the rated power.

The dry-type transformer cast in epoxy resin is increasingly ceasing to be perceived as a niche solution. Technological progress has made it possible to design dry-type transformers with ever-increasing power ratings, which maintain stable operating parameters and high reliability.

Therefore, the dry-type transformer will be a natural choice for indoor installations, where fire safety, low noise levels, and minimal maintenance requirements are of significant importance. Under such conditions, the absence of oil and resistance to environmental factors often outweigh the ability to handle very high power.

Constructions such as the TeoEco2 dry-type transformer demonstrate in practice that you don't have to compromise between safety and functionality.

The compact form, resin-cast windings, and limited maintenance needs mean that this type of solution fits well in facilities where both reliability and control of environmental conditions are valued. Resistance to moisture and dust means dry-type transformers are increasingly chosen for modern infrastructure and industrial installations.

Understanding the differences between transformers is worth supplementing with knowledge about their production process itself. The construction of an oil-immersed transformer is a complex, multi-stage process where every detail has a direct impact on the device's final reliability, durability, and parameter stability over time.

Stages such as core preparation, winding manufacturing, the drying process, or oil filling are not formalities, but the foundation of quality.

If you want to see what this looks like in practice, it's worth checking out the material:

How a transformer is made: 10 stages of oil-immersed transformer production

which step by step shows where the durability and predictable operation of these devices come from.

The right transformer – not the "better" one

The differences between an oil-immersed and a dry-type, cast-resin transformer do not boil down to a single technical parameter. They encompass construction, cooling method, safety level, and the very philosophy of designing the entire installation. In practice, the choice of a transformer is increasingly less a "typical" decision and more often an element of a consciously built energy strategy.

The best answer to the question "which transformer is better" is captured by a timeless quote from a classic: "it depends" ;-)

A much more sensible starting point, therefore, is the question of which transformer is right for a specific application and specific operating conditions.

Considering the location, required power, load characteristics, and reliability expectations allows for making decisions that pay off over time and reduce the risk of problems during operation. It is precisely at this stage that it is easiest to build an installation tailored to real needs, instead of later correcting it with costly compromises.

If you want to examine transformer solutions in a practical context and see how different approaches perform in specific applications, it's also worth checking out the full range of Energeks transformers.

If this text was useful to you, we probably look at the energy sector from a similar perspective.

On Energeks LinkedIn we continue these conversations without shortcuts or simplifications; you're also invited to get in touch.

Sources:

A scientific platform gathering technical publications and research in the fields of electrical engineering, power engineering, and transformer construction.

Reviews

No reviews!